Light emitting diode lamp 3-dimentional phase transition heat dissipation method and device

A technology of light-emitting diodes and heat sinks, which is applied in the direction of lighting devices, cooling/heating devices of lighting devices, light sources, etc., to achieve the effects of reducing system thermal resistance, reducing the complexity of production processes, and reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

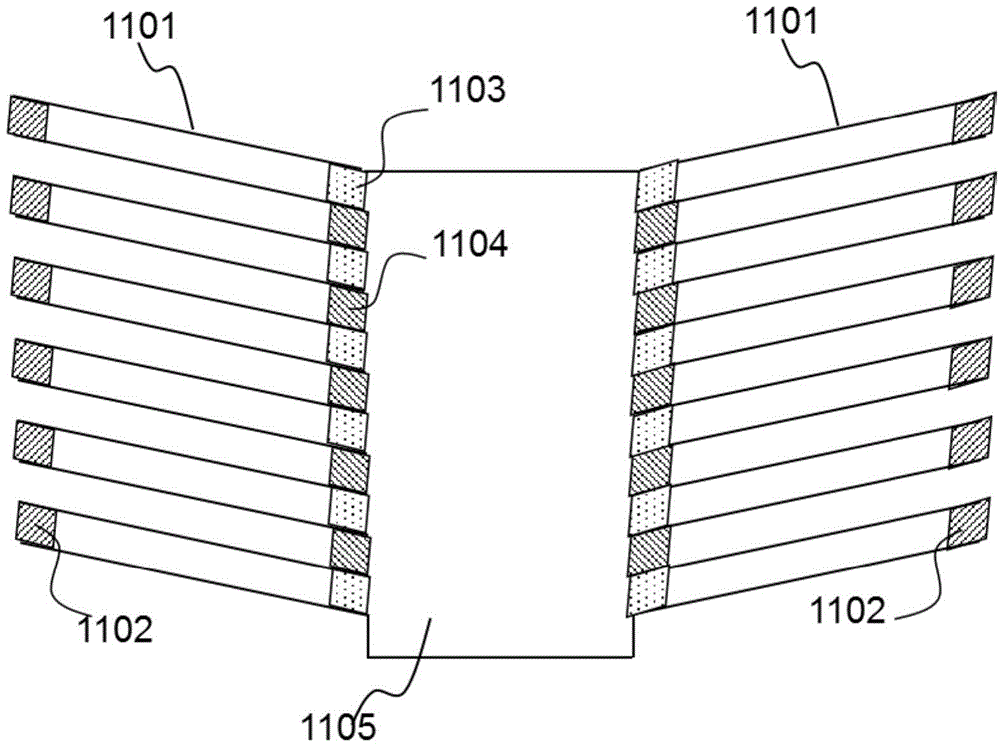

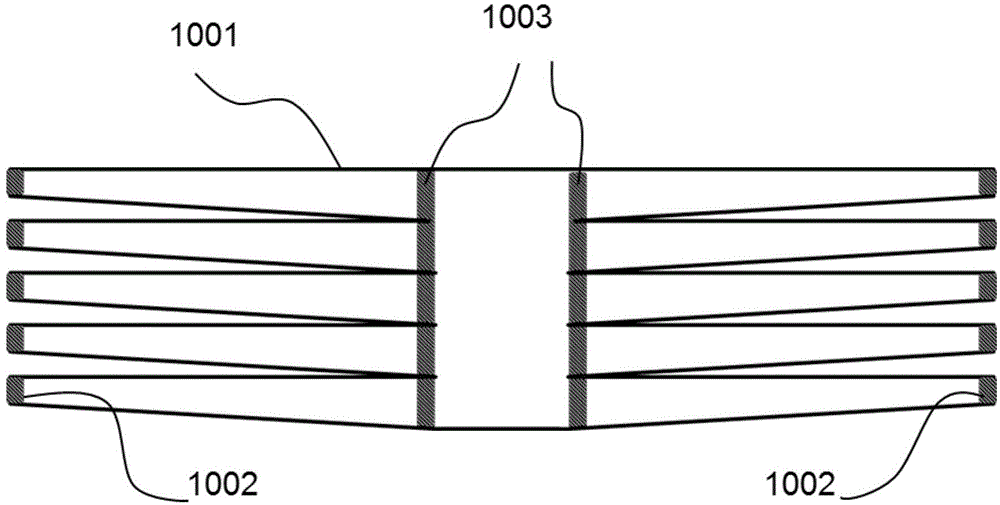

[0058] Embodiment 1 of the 3-dimensional phase change heat dissipation method and device for light-emitting diode lamps provided by the present invention is as follows: figure 1 As shown, the multi-layer fin structure constitutes a condenser 105 , which is sequentially connected with a liquid storage tank 104 of a storage liquid-gas phase change working medium 103 and an evaporator 102 to form an airtight hollow cavity 110 .

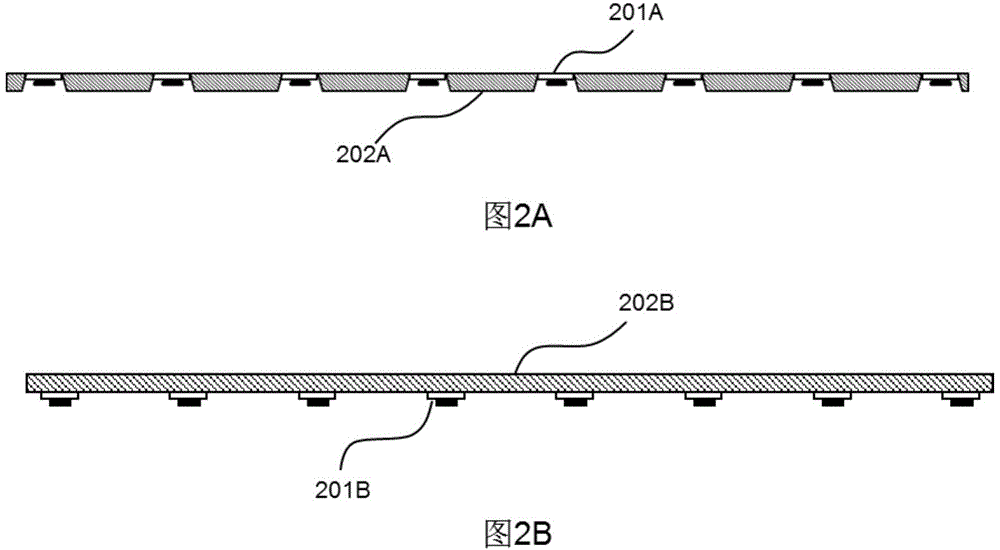

[0059] Each fin structure in the condenser 105 is composed of two ring-shaped high thermal conductivity material sheets. The high thermal conductivity material can be copper, aluminum or high thermal conductivity plastic. The thickness of the hollow space between the ring-shaped high thermal conductivity material sheets is about 1-20mm. The plane where each fin structure is located is parallel to the surface of the evaporator.

[0060] The liquid-gas phase change material can be selected from water or alcohol, and is stored in the liquid storage tank 104...

Embodiment 2

[0066] Embodiment 2 of the 3-dimensional phase change heat dissipation method and device for light-emitting diode lamps provided by the present invention is as follows: Figure 4 As shown, when the actual working environment temperature is higher than the expected working temperature of LED lamps, this structure can be adopted. and figure 1 The structure of the shown embodiment 1 is similar. The multi-layer fin structure constitutes a condenser 405, which is sequentially connected with the liquid storage tank 404 of the reserve liquid-gas phase change working medium 403 and the evaporator 402 with the LED chip 401 packaged on the outer surface, forming airtightness. The hollow cavity 410, together with the transparent mask 411, the LED chip driving circuit 406, and the electrical connection structure 407 constitute the second embodiment of the 3-dimensional phase change heat dissipation method and device for light-emitting diode lamps.

[0067]The difference between this embo...

Embodiment 3

[0069] Embodiment 3 of the 3-dimensional phase change heat dissipation method and device for light-emitting diode lamps provided by the present invention is as follows: Figure 5 shown. and figure 1 The structure of the shown embodiment 1 is similar, and the multi-layer fin structure constitutes a condenser 505, which is sequentially connected with the liquid storage tank 504 of the reserve liquid-gas phase change working medium 503 and the evaporator 502 with the LED chip 501 packaged on the outer surface, forming airtightness The hollow cavity 510, together with the transparent mask 511, the LED chip driving circuit 506, and the electrical connection structure 507 constitute Embodiment 3 of the 3-dimensional phase change heat dissipation method and device for light-emitting diode lamps.

[0070] The difference between this embodiment and Embodiment 1 is that the plane where each fin structure is located is perpendicular to the surface of the evaporator. The upper part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com