Preparation method of high-corrosion-resistance protective coating on surface of neodymium-iron-boron magnet

A protective coating, NdFeB technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of difficult control of reactive sputtering process, reduction of film-forming particle energy, brittle breakage and falling off, etc. , to achieve the effects of eliminating target poisoning, improving corrosion resistance, and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

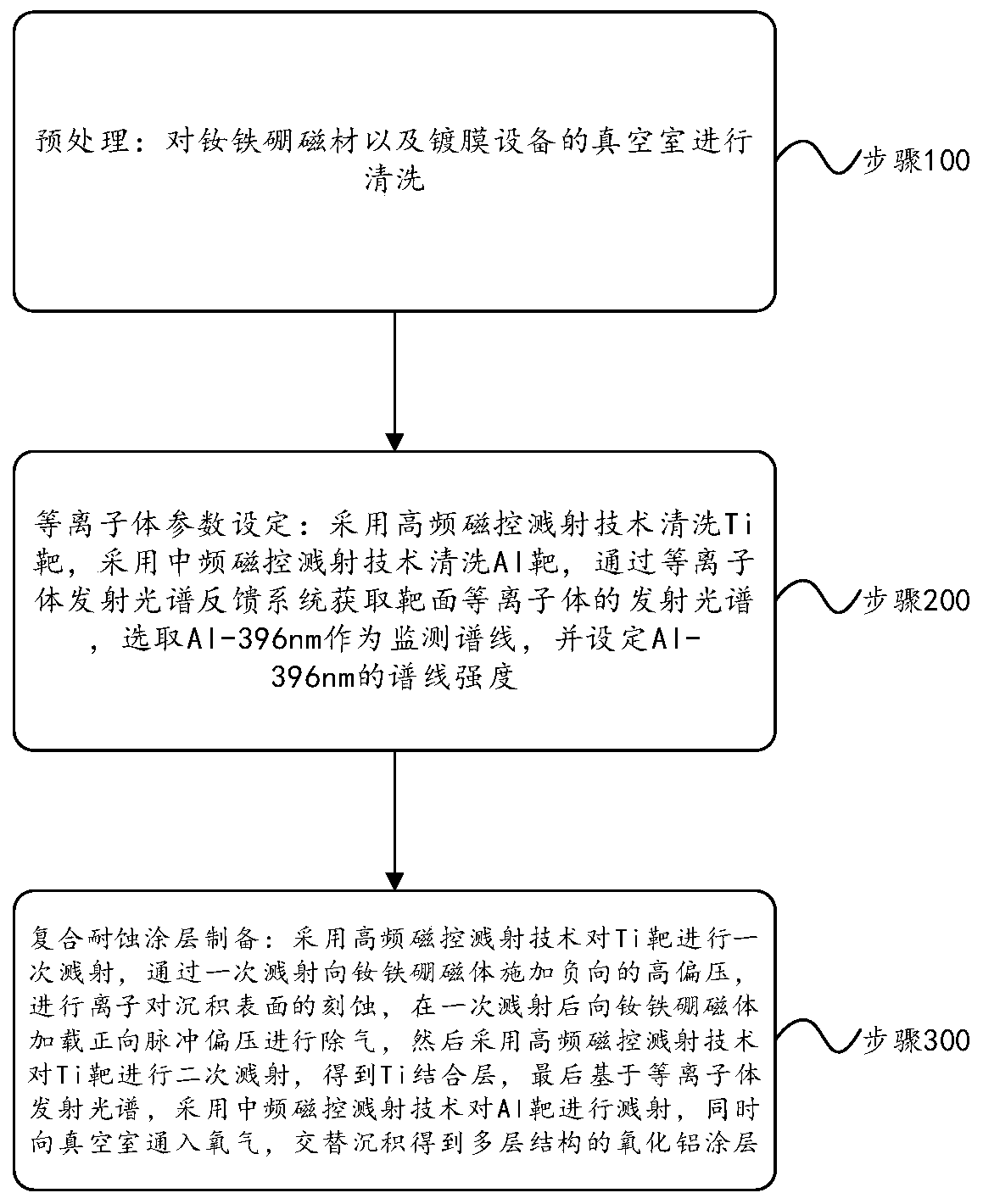

[0036] figure 1 A flow chart of a method for preparing a high corrosion-resistant protective coating on the surface of an NdFeB magnet provided in an embodiment of the present application, as shown in figure 1 As shown, the embodiment of the present application provides a method for preparing a high corrosion-resistant protective coating on the surface of an NdFeB magnet, including:

[0037] Step 100, pretreatment: cleaning the NdFeB magnet and the vacuum chamber of the coating equipment, this step specifically includes:

[0038] Step 101. Magnet pretreatment: Chamfering the NdFeB magnet and putting it into a vibratory grinder to obtain an NdFeB magnet with a corner arc not less than 0.5mm, followed by sandblasting and ultrasonication of an acid-base solution Cleaning, use the air pump to dry the surface of the magnet and put it into the vacuum chamber of the coating equipment;

[0039] Step 102, air path cleaning: pump the air pressure of the vacuum chamber to 1.0×10 -3 Be...

Embodiment 2

[0071] This embodiment is a method for preparing a high corrosion-resistant protective coating on the surface of an NdFeB magnet. In this embodiment, the spectral line intensity at Al-396nm is 60% to prepare a high corrosion-resistant protective coating on the surface of an NdFeB magnet. The method includes the following steps:

[0072] (1) Pretreatment:

[0073] (1) Magnet pretreatment: chamfering will be carried out, and put into a vibrating grinder to obtain NdFeB magnets with corner arcs not less than 0.5mm, followed by sandblasting and ultrasonic cleaning of acid-base solutions, using air The pump dries the surface of the magnet and puts it into the vacuum chamber of the coating equipment;

[0074] Wherein, the size of the NdFeB magnet in this embodiment is 60*60*10 mm.

[0075] (2) Gas path cleaning: pump the air pressure of the vacuum chamber to 1.0×10 -3 Below Pa, pass argon and oxygen into the vacuum chamber to clean the gas path.

[0076] (3) Ion source bombardme...

Embodiment 3

[0103] This example is a method for preparing a high corrosion-resistant protective coating on the surface of an NdFeB magnet. In this example, the spectral line intensity at Al-396nm is 65% to prepare a high corrosion-resistant protective coating on the surface of an NdFeB magnet. The method includes the following steps:

[0104] (1) Pretreatment

[0105] (1) Magnet pretreatment: chamfer the NdFeB magnet (size 30*10*5mm), put it into a vibratory grinder, obtain NdFeB magnets with corner arcs not less than 0.5mm, and then carry out For sandblasting and ultrasonic cleaning of acid and alkaline solutions, the air pump is used to dry the surface of the magnet and put it in the vacuum chamber of the coating equipment.

[0106] (2) Gas path cleaning: pump the air pressure of the vacuum chamber to 1.0×10 -3 Below Pa, pass argon and oxygen into the vacuum chamber to clean the gas path.

[0107] (3) Ion source bombardment cleaning: close the front baffle of the cathode target and ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com