High-reliability thermoelectric refrigeration sheet and packaging method thereof

A technology of thermoelectric cooling sheets and thermocouples, which is applied in the manufacture/processing of thermoelectric devices, parts of thermoelectric devices, and thermoelectric devices that only use the Peltier or Seebeck effect, etc. It can solve the problems of crack formation and affecting thermoelectric transport performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] The invention provides a preparation method of a thermoelectric refrigeration sheet, comprising the following steps:

[0079] 1) preparing a nano metal needle cone structure on the surface of the copper structure layer of the copper clad substrate to obtain a copper clad substrate with nano metal needle cones on the surface;

[0080] A nickel metal barrier layer is deposited on the surface of the semiconductor material, and a nano-metal needle-taper structure is prepared on the nickel metal barrier layer to form the package connection surface A;

[0081] 2) compound porous graphene on the nano metal needle cone of the copper-clad substrate with the nano metal needle cone on the surface obtained in the above steps, to form the encapsulation connection surface B;

[0082] After the package connection surface A and the package connection surface B are butted together, a package connection layer is formed by hot pressing and packaging, and a thermoelectric cooling sheet is ...

Embodiment 1

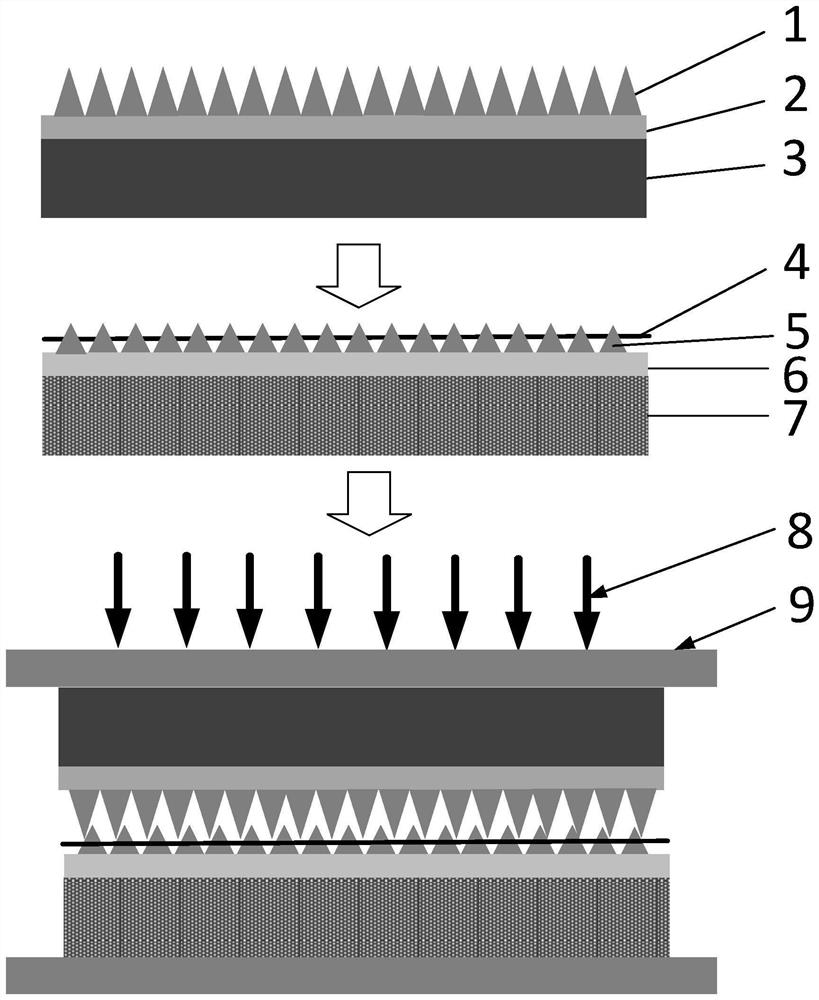

[0109] see figure 1 , figure 1 It is a schematic diagram of the structure and packaging process of the thermoelectric refrigeration sheet prepared in the embodiment of the present invention.

[0110] Among them, 1 is the nano-nickel needle cone structure, 2 is the metal nickel layer, 3 is, 4 is, 5 is, 6 is the copper surface layer of the copper-clad ceramic substrate, 7 is the copper-clad ceramic substrate, 8 is the applied pressure, 9 for the hot plate.

[0111] like figure 1As shown, the encapsulation method of the thermoelectric refrigeration sheet of the present invention includes:

[0112] (1) The bonding surface of the thermoelectric element 3 is cleaned by a standard RCA process, then metal nickel 2 (Ni) is deposited on the substrate by a sputtering process with a thickness of 1 μm, and finally a nano-nickel needle-cone structure 1 is prepared on the nickel layer. Method Including: the raw materials used are nickel chloride hexahydrate (200g / L), boric acid (35g / L), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com