Modular efficient homothermal energy-saving steam engine system

A steam engine and modular technology, which is applied in steam boilers, control systems, steam generation, etc., can solve the problems of uncontrollable steam water content, short hot gas burning time, slow steam speed, etc., and achieve fast, stable, efficient and improved steam output. Effect of heat utilization rate and improvement of heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

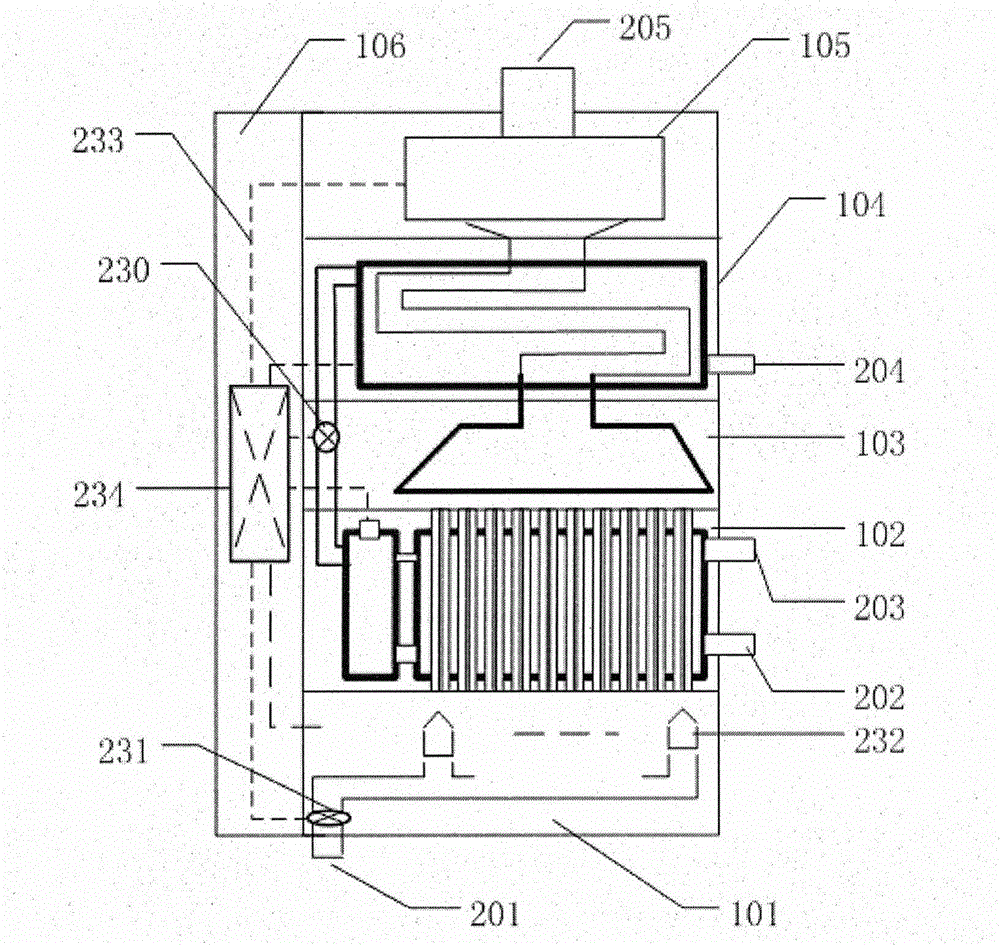

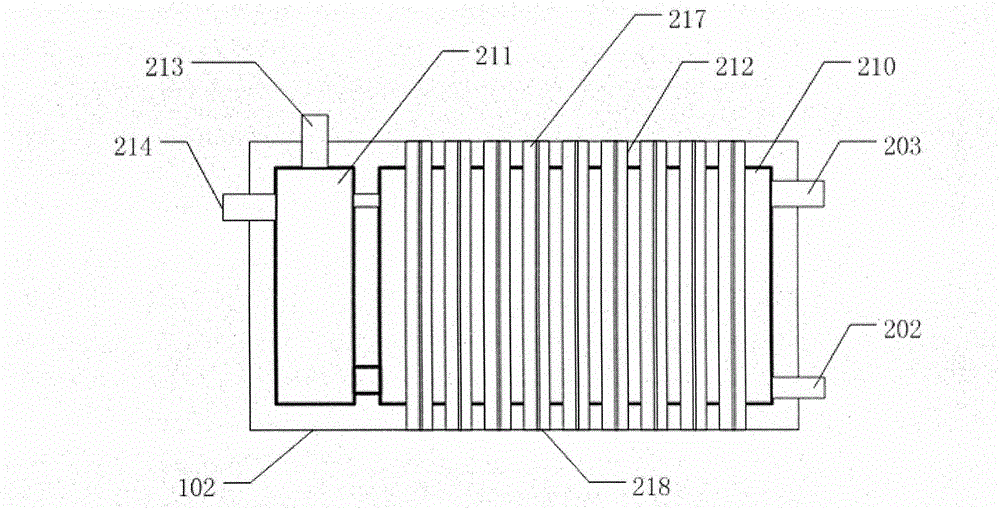

[0021] exist figure 1Among them, it can be clearly understood that the minimum system of the present invention has six functional modules on the frame, and the combustion chamber (101), steam generation chamber (102), waste heat concentrator (103), preheating Chamber (104), suction device (105), and the corresponding control cables of intelligent controller (106) are connected in the remaining five parts. The system also has five external interfaces, which are the air inlet (201) connected to the combustion chamber (101), the steam outlet (203) and the sewage outlet (202) connected to the steam generation chamber (102), and the preheating port (202). The water inlet (204) communicated with the chamber (104), and the exhaust port (205) communicated with the suction device (105). The air inlet (201) is connected to gas through pipelines, the water inlet (204) is connected to tap water, the steam outlet (203) is connected to facilities requiring steam, and the exhaust port (205)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com