Multiple-effect hot air seed drying device

A technology of drying device and hot air device, which is applied in the direction of drying gas arrangement, drying solid materials, local agitation dryer, etc., can solve the problems of affecting seed germination rate, high energy consumption, high labor intensity, etc., so as to avoid poor drying effect Good, reduce operating cost, use safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

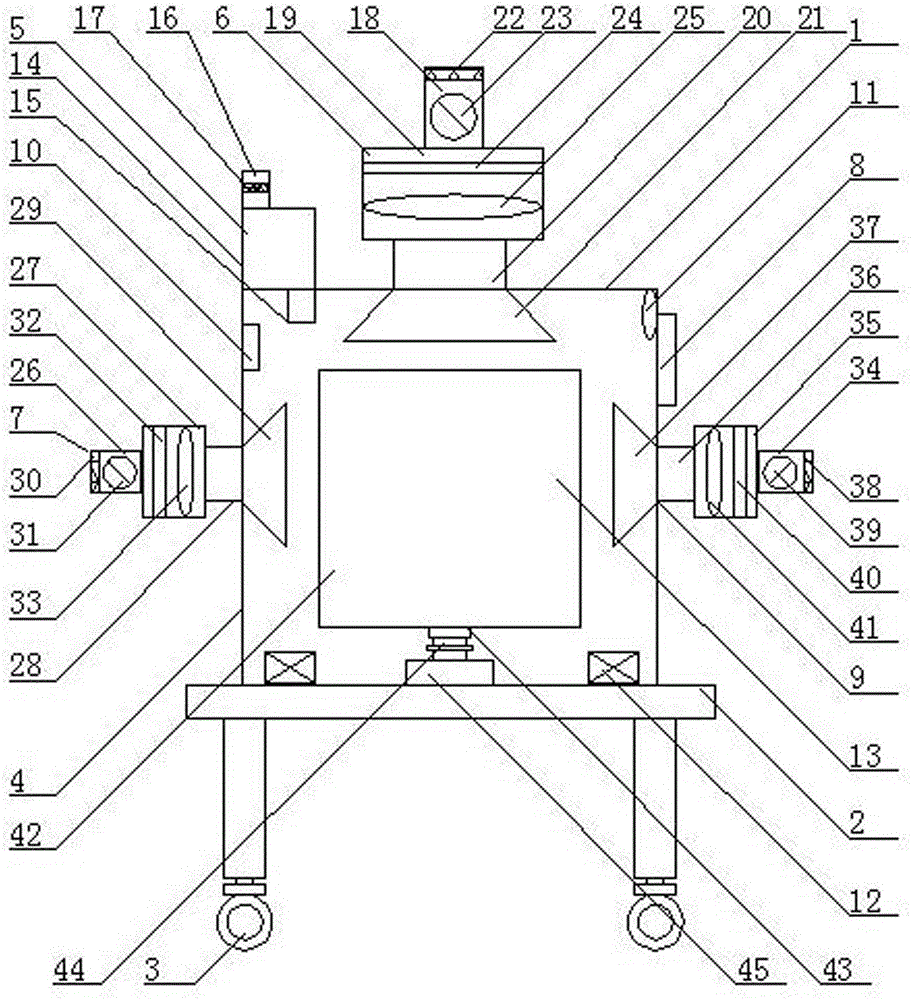

[0017] As shown in the figure, a multi-effect hot air seed drying device includes a fuselage 1, a frame 2 is installed at the lower end of the fuselage 1, casters 3 are installed at the bottom end of the frame 2, and a drying box is installed at the upper end of the frame 2 4. The dehumidifying device 5 is installed on the left side of the top of the drying box 4, the first hot air device 6 is installed in the middle of the top of the drying box 4, the second hot air device 7 is installed on the left side of the drying box 4, and the drying box 4. A controller 8 is installed at the upper end of the right side, a third hot air device 9 is installed at the middle end of the right side of the drying box 4, a temperature sensor 10 is installed at the upper left side of the inside of the drying box 4, and a humidity sensor 10 is installed at the upper right end of the inside of the drying box 4. A sensor 11, a circulation fan 12 is installed on the left and right sides of the inne...

Embodiment 2

[0019] As shown in the figure, the dehumidifier 5 is composed of a dehumidifier 14, an air suction pipe 15, and an exhaust pipe 16. The air suction pipe 15 is installed at the bottom of the dehumidifier 14, and the air suction pipe 15 is installed at On the left side of the top of the drying box 4, an exhaust pipe 16 is installed on the left side of the top of the dehumidifier 14, and an activated carbon filter screen 17 is installed inside the exhaust pipe 16.

Embodiment 3

[0021] As shown in the figure, the first hot air device 6 is composed of a first air suction pipe 18, a first hot air chamber 19, a first air inlet pipe 20 and a first air inlet duct 21. The top end of the first hot air chamber 19 is Install the first suction pipe 18, the bottom end of the first hot air chamber 19 is connected to the first air inlet duct 21 through the first air inlet pipe 20, and the first air inlet duct 21 is installed in the middle of the top inside the drying box 4 The first filter panel 22 is installed at the mouth of the first suction pipe 18, the first suction fan 23 is installed inside the first suction pipe 18, and the first ultraviolet extinguisher is installed at the upper end of the first hot air chamber 19. Bacteria lamp tube 24, the first heat exchanger 25 is installed at the lower end of the first ultraviolet sterilizing lamp tube 24.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com