Processing technology of fermented walnut milk

A processing technology and technology of walnut milk, applied in the field of processing technology of fermented walnut milk, can solve the problems of poor taste, impure taste, unstable system and the like of walnut milk, and achieve hard and crisp texture, good peeling effect and better taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

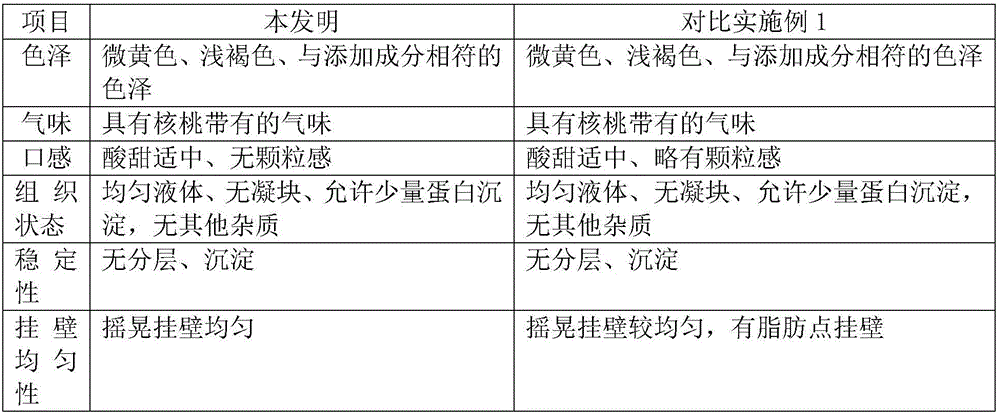

Examples

Embodiment 1

[0040] 1. Degreasing of walnut kernels: degreasing by low-temperature cold rolling process;

[0041] 2. Peeling: including the following steps,

[0042] (1) walnut kernels are degreased to obtain walnut meal, and the walnut meal is passed through a 50-mesh sieve;

[0043] (2), preparation of lye: mix sodium hydroxide with pure water, configure it into a sodium hydroxide solution with a concentration of 0.1%, and heat it to above 90°C;

[0044] (3), soaking: soak the walnut meal to be peeled in the sodium hydroxide solution of step (2), soak for 3min, and start stirring during the soaking process;

[0045] (4), discharge lye, discharge walnut dregs: after soaking completes, discharge soaking lye, after lye discharges, soaked walnut dregs are discharged;

[0046] (5), peeling and cleaning: the soaked walnut meal is washed with a high-pressure water gun to clean the walnut meal skin and impurities, and after cleaning, the impurities are removed;

[0047] (6), preparation of peel...

Embodiment 2

[0060] Further, before the refining operation, the peeled walnut kernels are toasted to further ensure the flavor of the fermented walnut milk, as follows:

[0061] 1. Degreasing of walnut kernels: degreasing by low-temperature cold rolling process;

[0062] 2. Peeling: including the following steps,

[0063] (1) walnut kernels are degreased to obtain walnut meal, and the walnut meal is passed through a 50-mesh sieve;

[0064] (2), the preparation of lye: sodium hydroxide is mixed with pure water, is configured into the sodium hydroxide solution that concentration is 0.2%, and is heated to above 90 ℃;

[0065] (3), soaking: soak the walnut meal to be peeled in the sodium hydroxide solution of step (2), soak for 2min, and start stirring during the soaking process;

[0066] (4), discharge lye, discharge walnut dregs: after soaking completes, discharge soaking lye, after lye discharges, soaked walnut dregs are discharged;

[0067] (5), peeling and cleaning: the soaked walnut m...

Embodiment 3

[0082] 1. Degreasing of walnut kernels: degreasing by low-temperature cold rolling process;

[0083] 2. Peeling: including the following steps,

[0084] (1) walnut kernels are degreased to obtain walnut meal, and the walnut meal is passed through a 50-mesh sieve;

[0085] (2), preparation of lye: mix sodium hydroxide with pure water, configure it into a sodium hydroxide solution with a concentration of 0.15%, and heat it to above 100°C;

[0086] (3), soaking: soak the walnut meal to be peeled in the sodium hydroxide solution of step (2), soak for 2.5min, and start stirring during the soaking process;

[0087] (4), discharge lye, discharge walnut dregs: after soaking completes, discharge soaking lye, after lye discharges, soaked walnut dregs are discharged;

[0088] (5), peeling and cleaning: the soaked walnut meal is washed with a high-pressure water gun to clean the walnut meal skin and impurities, and after cleaning, the impurities are removed;

[0089] (6), preparation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com