Sludge layer filtering and settling pond and method thereof

A sludge layer and sedimentation tank technology, applied in the field of sludge layer filtration sedimentation tank, can solve the problems of large area of sedimentation tank, large horizontal area of sedimentation tank, complex structure of filter tank, etc. Operation management, good effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

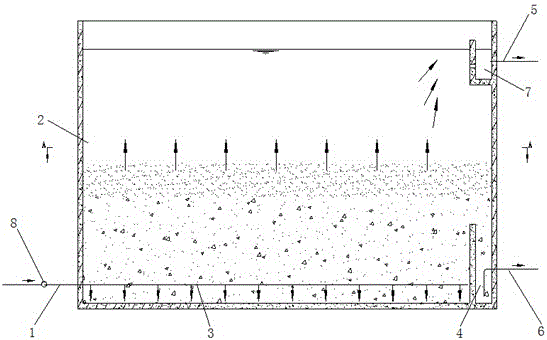

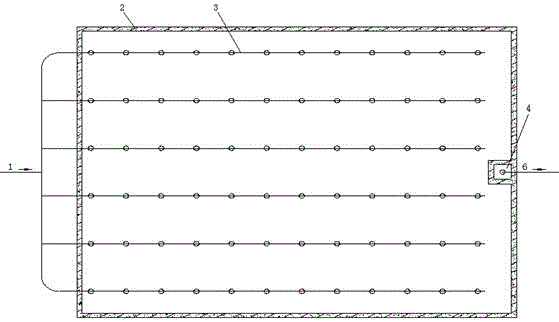

[0030] As shown in the figure, the sludge filter sedimentation tank includes a tank body 2, an inlet pipe 1, an outlet pipe 5, and a mud discharge pipe 6. A mud discharge pipe 6 and a water outlet pipe 5 are arranged on the top. Around the mud outlet of the mud discharge pipe 6, an upper opening enclosure is formed to form a sludge bucket 4. An upper opening is arranged around the water outlet of the water outlet pipe 5. The slag separation plate forms a clear water bucket 7; the water inlet pipe 1 is also connected to the water distributor 3 arranged in the pool body 2, so that the incoming water can be evenly filtered after being distributed. The water distributors 3 are several arranged in parallel; a pump 8 is also arranged on the water inlet pipe 1 to control the upstream flow rate of the muddy water to be treated.

[0031] The method for sludge l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com