A twin-tower meda landfill gas treatment system

A landfill gas and tower-type technology, which is applied to the separation of dispersed particles, waste fuel, chemical instruments and methods, etc., can solve the problems of different rates, differences in reactions, etc., and achieve the effect of no pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

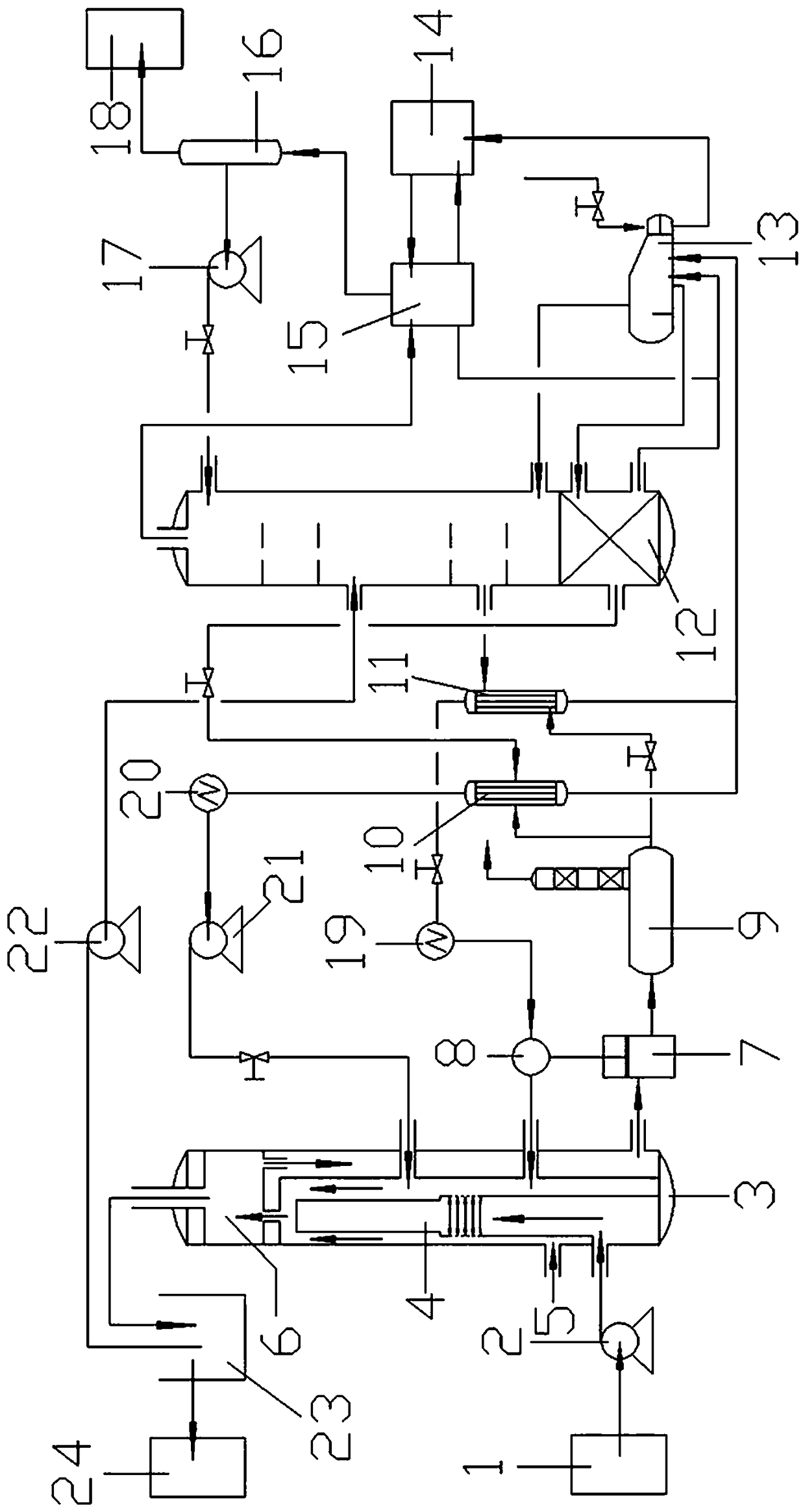

[0024]As shown in the figure, the present invention includes a feed gas tank (1), a feed gas booster pump (2), an absorption tower (3), a casing microreactor (4), an activator piperazine inlet (5), a gas-liquid Separator (6), hydraulic turbine (7), circulating pump (8), flash evaporator (9), lean-rich liquid heat exchanger (10), semi-lean liquid heat exchanger (11), regeneration tower (12 ), reboiler (13), cooling water tank (14), heat pump (15), separator (16), acid water reflux pump (17), acid gas recovery tank (18), semi-lean liquid aftercooler (19 ), lean liquid aftercooler (20), MDEA circulation pump (21), washing tank reflux pump (22), water washing tank (23), treated gas collection box (24), casing microreactor (4) In the cavity on one side of the absorption tower (3), the piperazine inlet (5) of the activator is connected to the outer cavity of the casing microreactor (4) and is arranged at the lower part of the cavity, and the inlet at the lower end of the casing micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com