A straw board production and processing system

A technology of processing system and production system, applied in the direction of wood processing equipment, manufacturing tools, layered products, etc., can solve the problems of unstable production quality, loose straw, low production speed, etc., and achieve reasonable equipment collocation and good straw looseness. , to prevent the effect of poor looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

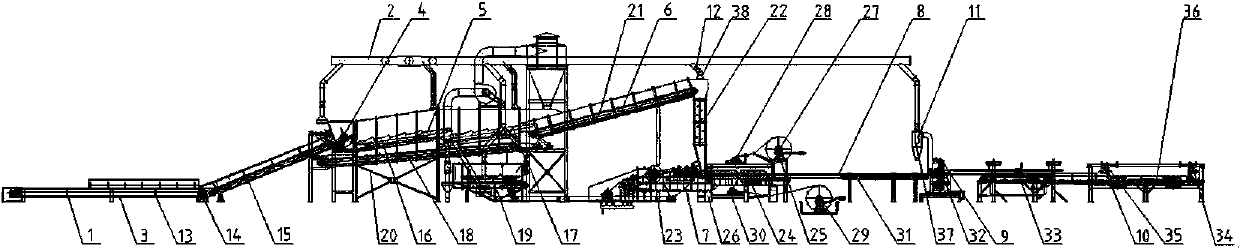

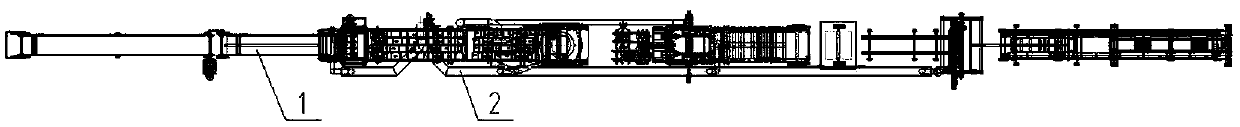

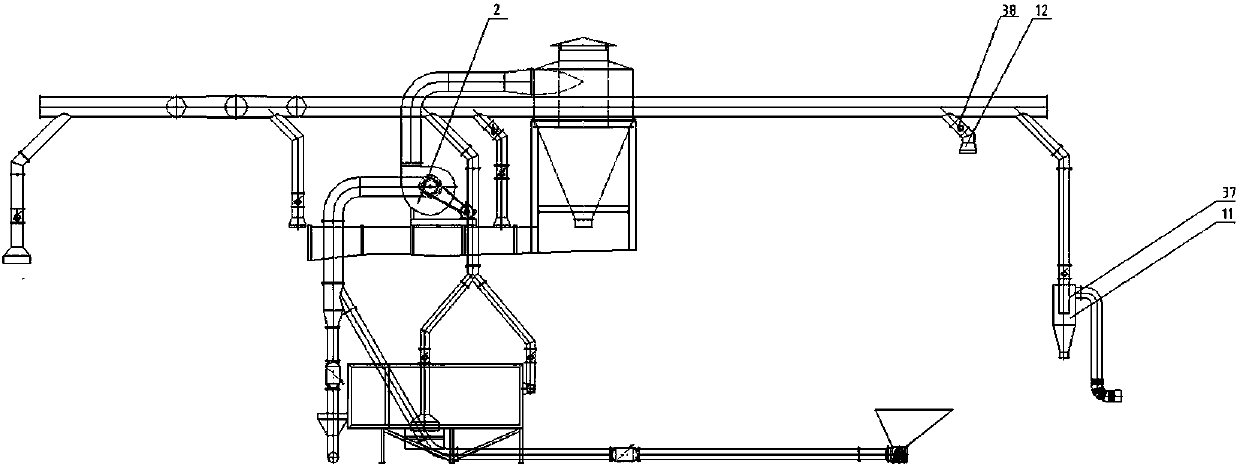

[0038] As shown in the figure, a straw board production and processing system includes a main production system (1), a material recovery and dust removal system (2), and the material recovery and dust removal system (2) is installed at the upper end of the main production system (1); The main production system (1) consists of a grass feeding module (3), a beam opening module (4), a stepping and separating module (5), a straw conveying module (6), a forming module (7), and a conveying module (8 ), a cutting module (9), and an end-capping module (10); the material recovery and dust removal system (2) is composed of a material recovery module (11) and a dust removal module (12); the grass feeding module (3 ), opening module (4), stepping separation module (5), straw conveying module (6), forming module (7), conveying module (8), cutting module (9), end-sealing module (10) from the left Connect to the right in turn; the material recovery module (11) is connected to the dust remova...

Embodiment 2

[0040] As shown in the figure, the grass feeding module (3) is composed of a roller feeder (13), a planetary cycloid reducer (14), and an accumulation chain conveyor (15). The roller feeder ( 13) The right end is connected to the accumulating chain plate conveyor (15) through the planetary cycloid reducer (14); Composed of throwing rods, curved throwing rods, and a support frame; the mowing wheel device is on the upper right end of the accumulation chain conveyor (15), the bottom of the driving wheel is supported by the supporting frame, the mowing wheel is connected to the driving wheel, and the driving wheel is connected to the accumulation chain Plate conveyor (15); the three-phase asynchronous motor and the rolling end cylinder are installed on the support frame, and are installed on the right end of the grass wheel, and the rolling end cylinder is equipped with a plurality of straight throwing rods and a plurality of curved throwing rods , The three-phase asynchronous mot...

Embodiment 3

[0042] As shown in the figure, the step separation module (5) consists of a first step motor (16), a second step motor (17), a waste conveyor (18), a screening machine (19), a support frame (20 ) form; the first stepper motor (16), the second stepper motor (17), and the waste conveyor (18) are all installed on the support frame (20); the first stepper motor (16) device On the left side of the top of the support frame (20), the second stepping motor (17) is installed on the lower side of the right end of the first stepping motor (16), and the waste conveyor (18) is installed on the first stepping motor (16), the second The bottom of the second stepper motor (17), the screening machine (19) is installed on the right side of the bottom of the waste conveyor (18); the right end of the second stepper motor (17) is connected to the straw delivery module (6); the straw The conveying module (6) is composed of a loose straw conveyor (21), a feeder (22), and a support frame; the loose s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com