Method for manufacturing Fe2O3 nanometer film curled tubes

A nano-film and nano-membrane technology, applied in the direction of iron oxide/iron hydroxide, iron oxide, etc., can solve the problems of cumbersome and complicated steps, contaminated materials, incomplete template removal, etc., and achieve simple preparation process, convenient operation, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

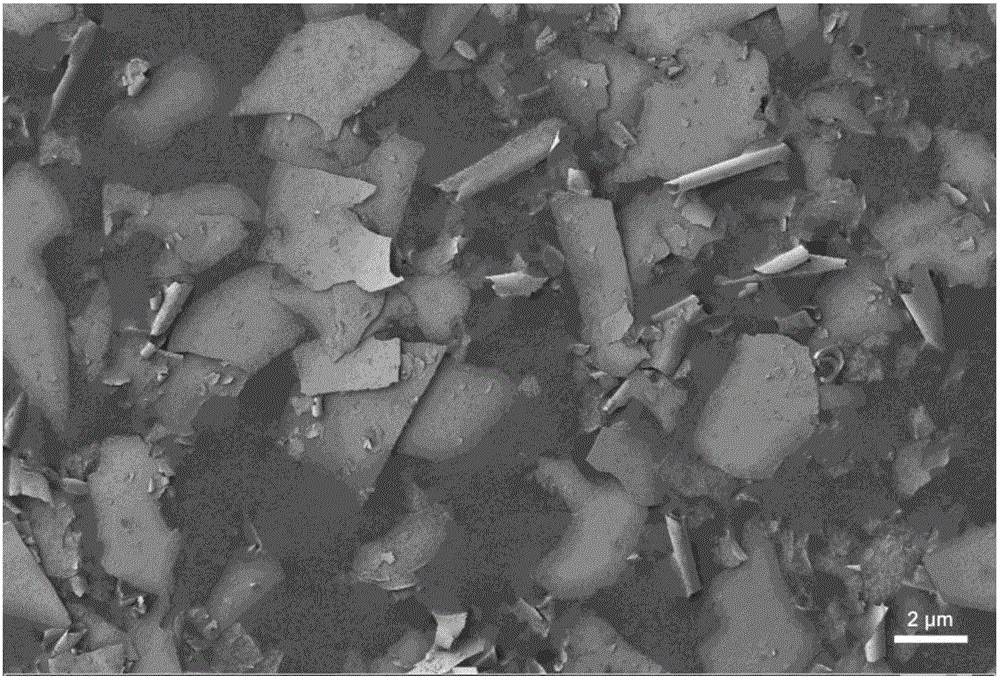

[0016] This embodiment prepares Fe 2 o 3 The specific process of nano-film crimping tube is as follows: first, deposit a layer of Al with a thickness of 50nm on the striped side of the aluminum foil using an electron beam evaporation coater 2 o 3 Nano film, a layer of Ti nano film with a thickness of 10nm, and a layer of Fe nano film with a thickness of 50nm; then put the aluminum foil in a NaOH solution with a concentration of 1M for 3h, and remove the Al by chemical corrosion. 2 o 3 and Ti nano-membrane, at the same time, Fe nano-membrane curled into a tubular structure under the released stress, and the resulting product was filtered and washed 3 times with deionized water, and then filtered and washed 3 times with ethanol and isopropanol successively, and then The filtered and washed product was subjected to CO 2 Supercritical drying for 12 hours to obtain Fe coiled tubes, and finally annealing the Fe coiled tubes in a tube furnace at 450 °C for 2 hours to prepare Fe ...

Embodiment 2

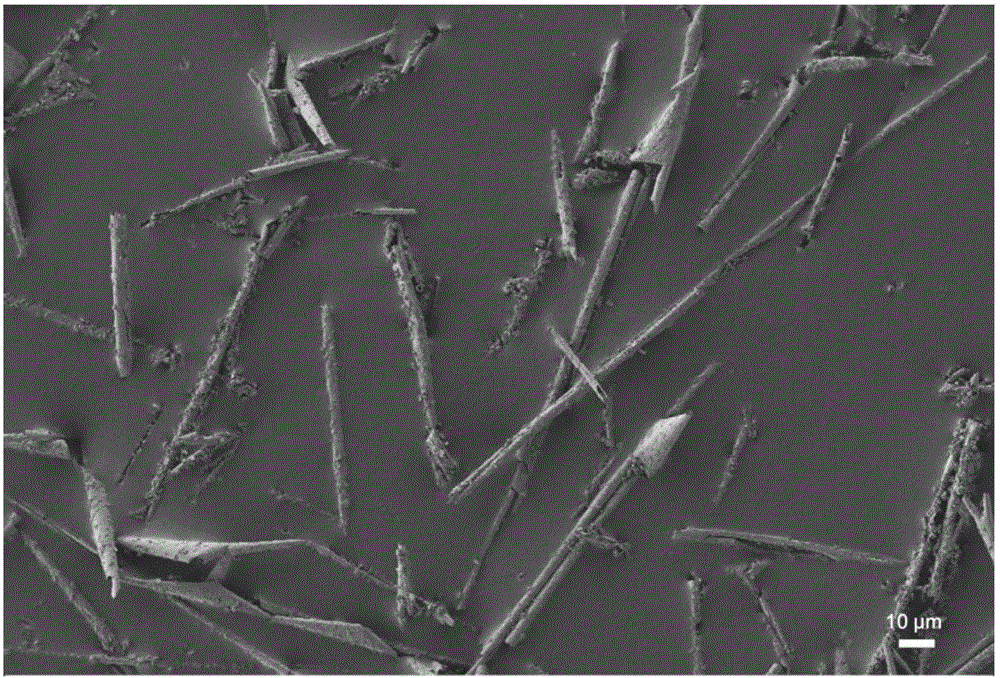

[0019] This embodiment prepares Fe 2 o 3 The specific process of nano-film crimping tube is as follows: first, deposit a layer of Al with a thickness of 50nm on the striped side of the aluminum foil using an electron beam evaporation coater 2 o 3 Nano film, a layer of 20nm thick Ti nano film, a layer of 20nm thick Fe nano film; then put the aluminum foil in a NaOH solution with a concentration of 1M for 3h, remove the Al by chemical corrosion 2 o 3 and Ti nano-membrane, at the same time, Fe nano-membrane curled into a tubular structure under the released stress, and the resulting product was filtered and washed 3 times with deionized water, and then filtered and washed 3 times with ethanol and isopropanol successively, and then The filtered and washed product was subjected to CO 2 Supercritical drying for 12 hours to obtain Fe coiled tubes, and finally annealing the Fe coiled tubes in a tube furnace at 450 ° C for 2 hours to prepare Fe 2 o 3 Nanomembrane crimp tube.

[...

Embodiment 3

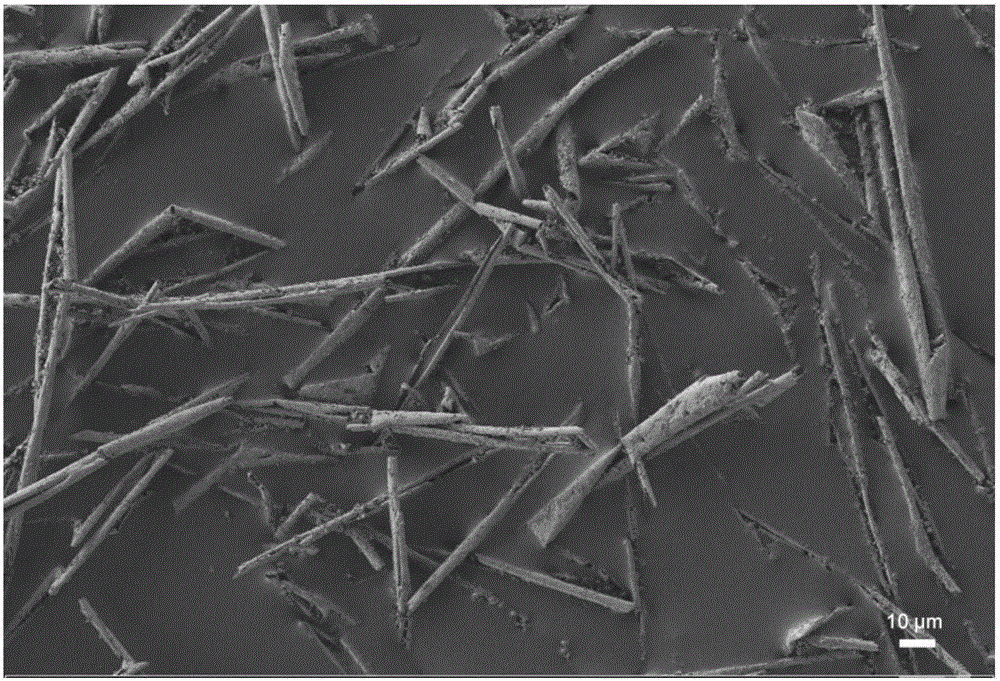

[0022] This embodiment prepares Fe 2 o 3 The specific process of nano-film crimping tube is as follows: first, deposit a layer of Al with a thickness of 50nm on the striped side of the aluminum foil using an electron beam evaporation coater 2 o 3 Nano film, a layer of 20nm thick Ti nano film, a layer of 35nm thick Fe nano film; then put the aluminum foil into the NaOH solution with a concentration of 1M for 3h, remove the Al by chemical corrosion 2 o 3 and Ti nano-membrane, at the same time, Fe nano-membrane curled into a tubular structure under the released stress, and the resulting product was filtered and washed 3 times with deionized water, and then filtered and washed 3 times with ethanol and isopropanol successively, and then The filtered and washed product was subjected to CO 2 Supercritical drying for 12 hours to obtain Fe coiled tubes; finally, the Fe coiled tubes were annealed in a tube furnace at 450 °C for 2 hours to prepare Fe 2 o 3 Nanomembrane crimp tube. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com