Sludge recovery and paper making method

A technology of sludge and compound microbial bacteria, applied in the field of papermaking, can solve problems such as environmental pollution, and achieve the effects of environmental protection, high dehydration efficiency and rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

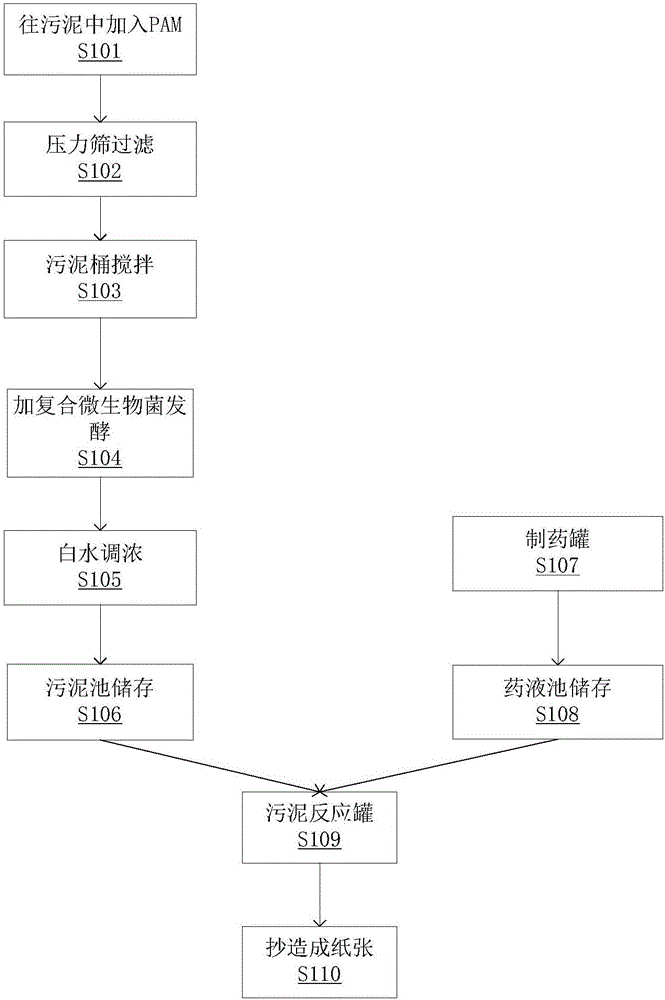

[0019] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

[0020] see figure 1 , first explain the English that will appear:

[0021] PAM: It is the abbreviation of Polyacrylamide, and the Chinese name is polyacrylamide. PAM is a non-ionic polymer flocculant commonly used in China, with a molecular weight of 1.5 million to 20 million and a commercial concentration of 8%. The organic polymer flocculant has a huge surface adsorption effect by forming larger flocs between particles.

[0022] In this embodiment, the steps are as follows:

[0023] S101: adding PAM to the sludge;

[0024] Add PAM to the sludge, stir well, and place it at room temperature for 4 hours, which can effectively dehydrate the sludge before the sludge enters the filter press. The mud cake is thicker, the dehydration e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com