Hydraulic separation method used for pipeline sludge, and system thereof

A hydraulic separation and sludge technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of large safety hazards, high labor costs, poor treatment effect, etc., to reduce sanitation and potential safety hazards, shortened washing time, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

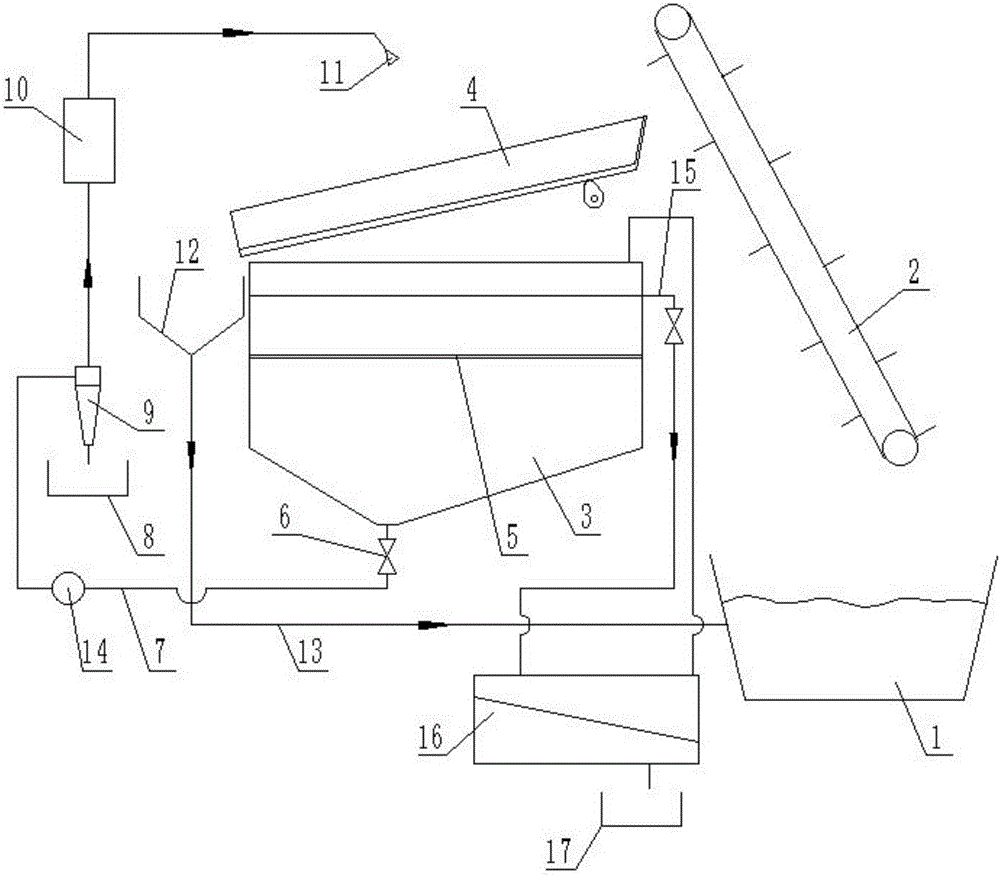

[0028] Embodiment: When in use, air-dry or sun-dry the pipeline sludge, and use a mill to grind it into powder, and the powder particle size is 1-3mm. The sludge powder is input into the top of the vibrating screen 4 on the water tank 3. With the vibration of the vibrating screen 4, the sludge with small particle size enters the water tank 3, and the large-sized sludge particles enter the hopper 12 and are sent back to the sludge through the conveyor belt 13 The pool 1 is lifted and filtered again; the sludge entering the water tank 3 enters the water, and the water is treated to make part of the suspended matter and floating matter; Excluded, the excluded suspended matter enters the solid-liquid separator 16 for solid-liquid separation, the generated waste residue enters the waste residue bucket 17, and the generated water flows back to the water tank 3 through the return pipe to continue to use; the sludge filtered by the filter screen 5 settles to the bottom of the water , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com