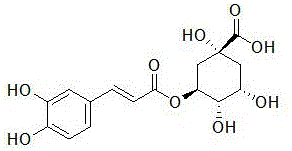

Preparing method for chlorogenic acid and similar compounds thereof

A compound, the technology of chlorogenic acid, applied in the field of medicine and chemical industry, can solve the problems of high cost, expensive equipment and materials, etc., and achieve the effect of simple method, low cost, high yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 10 kg of dried honeysuckle to 85% ethanol with a concentration of 6 times the weight of honeysuckle, reflux extraction at 85°C for 3 hours, repeat the extraction of the filter residue once after filtering, and combine 155 L of extracts; Concentrate to an extract at ℃; then dissolve the extract in water 3 times the weight of the extract, extract with ethyl acetate after dissolving to obtain an ethyl acetate extract, and concentrate the extract to 0.3 times the original extract, to obtain a concentrated solution; then use 0.1mol·L -1 Adjust the pH value of the concentrated solution to neutral with NaOH, pass through a D-101 macroporous resin column after filtration, then wash the macroporous resin column with 70% ethanol, combine the effluent and water washes, and concentrate at 70°C To a paste, dry at 60°C to obtain 325g of light green powder, the content of chlorogenic acid and its similar compounds is 90.1%; take 1g of the concentrated solution and dissolve it in m...

Embodiment 2

[0034] Add 10 kg of dried honeysuckle to 70% ethanol with 8 times the weight of honeysuckle, reflux and extract at 0°C for 2 hours, repeat the extraction of the filtered residue once, and combine 158 L of extracts; extract 70 Concentrate to an extract at ℃; then dissolve the extract in water with 5 times the weight of the extract, extract with ethyl acetate after dissolving to obtain an ethyl acetate extract, and concentrate the extract to 0.15 times the original extract, to obtain a concentrated solution; then use 0.1mol·L -1 Adjust the pH value of the concentrated solution to neutral with NaOH, pass through the NKA-9 macroporous resin column after filtration, then wash the macroporous resin column with 65% ethanol, combine the effluent and water washes, and concentrate at 70°C To a paste, dry at 60°C to obtain 355g of light green powder, the content of chlorogenic acid and its similar compounds is 85.4%; take 1.5g of the concentrated solution and dissolve it in methanol, use...

Embodiment 3

[0036] Add 10 kg of dried honeysuckle to 14 times the weight concentration of honeysuckle in ethanol with a concentration of 65%, reflux extraction at 65°C for 4 hours, repeat the extraction of the filter residue twice, and combine 156 L of extracts; extract 70 Concentrate to an extract at ℃; then dissolve the extract in water with 8 times the weight of the extract, extract with ethyl acetate after dissolving to obtain an ethyl acetate extract, and concentrate the extract to 0.1 times the original extract, to obtain a concentrated solution; then use 0.1mol·L -1 Adjust the pH value of the concentrated solution to neutral with NaOH, pass through the NKA-11 macroporous resin column after filtration, then wash the macroporous resin column with 60% ethanol, combine the effluent and water washings, and concentrate at 70°C To paste, dry at 60°C to obtain 325g of light green powder, the content of chlorogenic acid and its similar compounds is 89.6%; take 2g of the concentrated solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com