Modified polylactic acid 3D printing material based on ABS recycled materials

A 3D printing and polylactic acid technology, which is applied in the field of modified polylactic acid 3D printing materials and its preparation, can solve the problems of poor flexibility and reduced toughness of polylactic acid resin, and achieve improved impact strength, elongation at break, and production costs Low, the effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

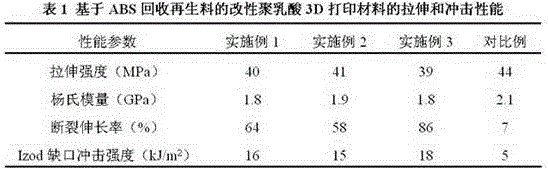

Embodiment 1

[0027] In parts by mass, weigh 55 parts of polylactic acid resin dried at 70°C for 10 hours in a vacuum oven, 30 parts of recycled ABS materials, 10 parts of ABS high rubber powder (60% glue content), maleic anhydride grafted 5 parts of ABS (ABS-g-MAH, MAH grafting rate 3%), premixed by a high-speed mixer at a speed of 1000rpm for 6 minutes, melted and kneaded the premixed material with a twin-screw extruder, and extruded lines After being cooled in a water tank, the pellets were pelletized by a pelletizer to obtain the composition pellets. The five-stage heating temperature of the barrel of the twin-screw extruder was set to 170, 185, 195, 205, and 210°C respectively, the temperature of the head was set to 215°C, and the screw speed was 100rpm.

[0028] The obtained composition particles were vacuum-dried, melted and extruded with a single-screw extruder, drawn and shaped into a 3D printing filament with a diameter of 1.75 mm. The five-stage heating temperature of the barrel...

Embodiment 2

[0031]In terms of parts by mass, weigh 45 parts of polylactic acid resin, 35 parts of ABS recycled materials, 13 parts of SBS, and SBS grafted with maleic anhydride (SBS-g-MAH, MAH Graft rate 4%) 7 parts, after premixing 8min with the rotating speed of 800rpm by high-speed mixer, the premixture is melted and kneaded with twin-screw extruder, and after the extruded lines are cooled by water tank, they are processed by pelletizer Pelletize to obtain composition granules. The five-stage heating temperature of the barrel of the twin-screw extruder was set to 175, 190, 200, 210, and 215°C respectively, the temperature of the head was set to 220°C, and the screw speed was 80rpm.

[0032] The obtained composition particles were vacuum-dried, melted and extruded with a single-screw extruder, drawn and shaped into a 3D printing filament with a diameter of 1.75 mm. The five-stage heating temperature of the barrel of the single-screw extruder was set to 180, 190, 200, 205, and 210°C res...

Embodiment 3

[0035] In terms of parts by mass, 65 parts of polylactic acid resin, 25 parts of ABS recycled materials, 7 parts of SEBS, and SEBS grafted with glycidyl methacrylate (SEBS-g- GMA, GMA graft rate 2%) 3 parts, after premixing 10min with the rotating speed of 600rpm through the high-speed mixer, the premix is melted and kneaded with the twin-screw extruder, and the extruded lines are cooled by the water tank The pelletizer pelletizes to obtain the composition pellets. The five-stage heating temperature of the barrel of the twin-screw extruder was set to 170, 180, 190, 200, and 205°C respectively, the temperature of the head was set to 210°C, and the screw speed was 60rpm.

[0036] The obtained composition particles were vacuum-dried, melted and extruded with a single-screw extruder, drawn and shaped into a 3D printing filament with a diameter of 1.75 mm. The five-stage heating temperature of the barrel of the single-screw extruder was set to 170, 180, 190, 195, and 200°C respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com