Method for preparing aluminum-silicon-iron alloy from high-aluminum coal gangue and conducting graded purification

A technology of high-alumina coal gangue and ferrosilicon alloy, which is applied in the fields of metallurgy and the environment, can solve problems such as shortage of bauxite resources and waste of resources, and achieve the effects of alleviating the shortage of bauxite resources, reducing iron content, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

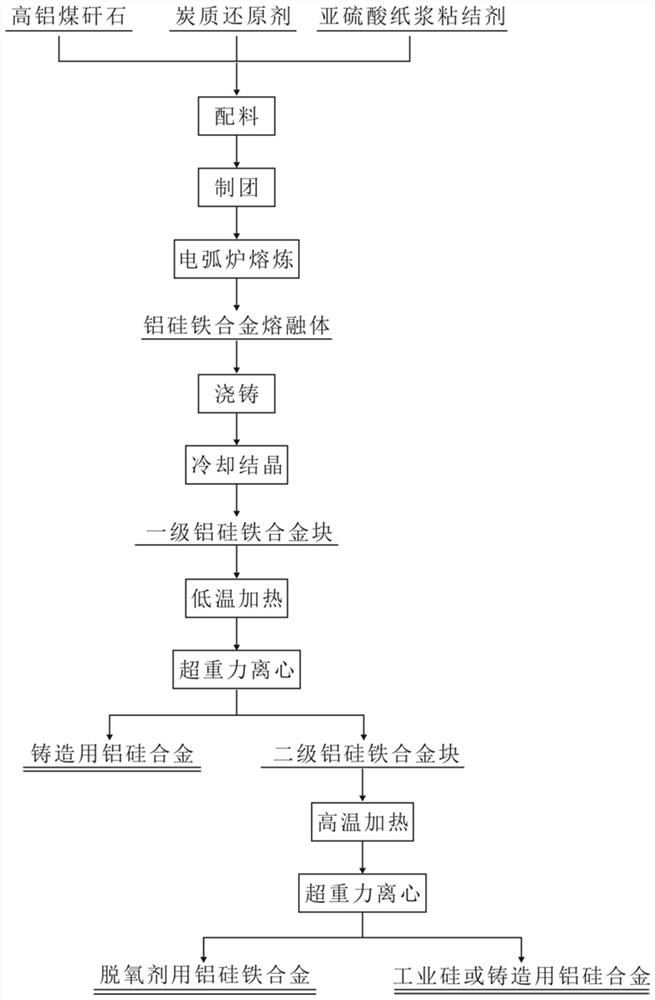

[0036] A method for preparing aluminum-silicon-ferroalloys by using high-alumina coal gangue and refining them step by step, the process flow chart is as follows figure 2 shown, including the following steps:

[0037] Crush 1 ton of high-alumina coal gangue and coal until the particle size is less than 100 mesh, and mix uniformly to form a mixed material, in which Al 2 o 3 The mass fraction is 48.32%, SiO 2 The mass fraction is 46.54%, Fe 2 o 3 The mass fraction is 0.63%, and the carbon content of the coal is 90% of the carbon content required for the complete reaction of the metal oxides and carbon in the coal gangue, and then sequentially add 6% of the mixed material mass of sulfurous acid pulp binder and 10% of water to carry out Mix the materials, and then make the mixed materials into pellets in the pellet machine, the pellet making pressure is 100MPa, dry and dehydrate the prepared pellets at 120°C to obtain dry pellets, the water content should not exceed 1%; Then...

Embodiment 2

[0040] A method for preparing aluminum-silicon-ferroalloys by using high-alumina coal gangue and refining them step by step, the process flow chart is as follows figure 2 shown, including the following steps:

[0041] Crush 1 ton of high-alumina coal gangue and coal until the particle size is less than 100 mesh, and mix uniformly to form a mixed material, in which Al 2 o 3 The mass fraction is 48.32%, SiO 2 The mass fraction is 46.54%, Fe 2 o 3 The mass fraction is 0.63%, and the carbon content of the coal is 90% of the amount of carbon required for the complete reaction of the metal oxide and carbon in the coal gangue, and then sequentially add 6% of the mixed material mass of sulfurous acid pulp binder, 10% of water Carry out mixing, and then make the mixed materials into pellets in the pellet machine, the pelletizing pressure is 100MPa, dry and dehydrate the prepared pellets at 120°C to obtain dry pellets, the moisture content should not exceed 1% ; Then put the dry m...

Embodiment 3

[0044] A method for preparing aluminum-silicon-ferroalloys by using high-alumina coal gangue and refining them step by step, the process flow chart is as follows figure 2 shown, including the following steps:

[0045] 1 ton of high-alumina coal gangue and coal are crushed to a particle size of less than 100 mesh, and mixed uniformly to form a mixed material, in which the coal gangue is composed of Al 2 o 3 The mass fraction is 48.32%, SiO 2 The mass fraction is 46.54%, Fe 2 o 3 The mass fraction is 0.63%, and the carbon content of the coal is 90% of the amount of carbon required for the complete reaction of the metal oxide and carbon in the coal gangue, and then sequentially add 6% of the mixed material mass of sulfurous acid pulp binder, 10% of water Carry out mixing, and then make the mixed materials into pellets in the pellet machine, the pelletizing pressure is 100MPa, dry and dehydrate the prepared pellets at 120°C to obtain dry pellets, the moisture content should n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com