Anti-adhesion agent for superabsorbent resin gel and preparation method thereof

A technology of super absorbent resin and anti-adhesive agent, applied in the field of anti-adhesive agent, can solve problems such as equipment rust, and achieve the effect of resisting equipment rust, improving lubricity and reducing interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Mix 69.8g of deionized water and 0.1g of Tween 80, and stir for 15min at a stirring speed of 3000r / min;

[0027] Then add 0.5g hydrogen peroxide, 1g liquid paraffin, 20g butyl oleate, 4g dodecyl alcohol ester, 0.1g Span 80, 0.2g n-octanol and 3g dimethyl silicone oil and continue to stir evenly, at a stirring speed of 2000r / min After stirring for 20min, stop stirring and discharging to obtain the anti-sticking agent for super absorbent resin gel;

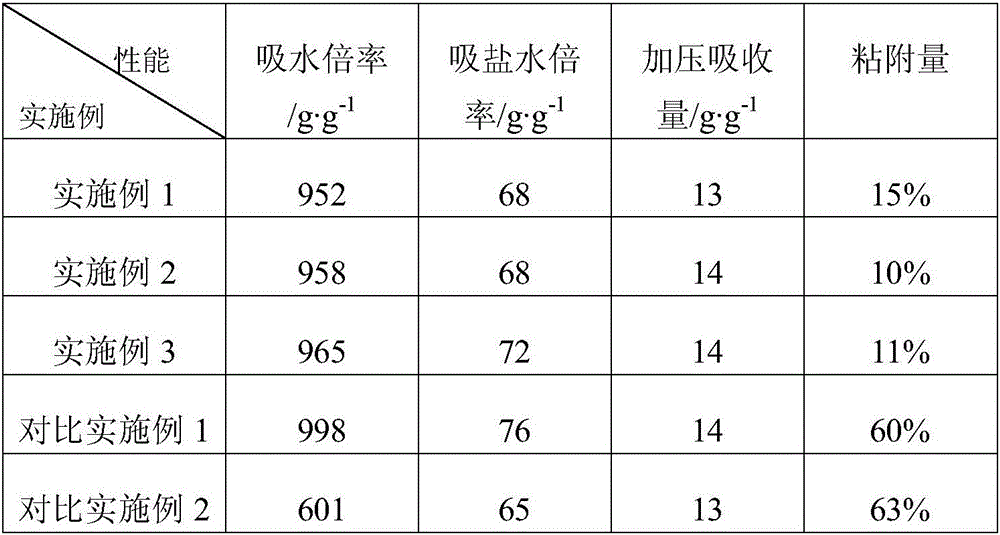

[0028] Pour the anti-sticking agent into the watering can, spray 5g of the anti-sticking agent on the surface of 100g of super absorbent resin gel, cut into strips, extrude and granulate by screw, dry, pulverize and sieve to obtain 60-100 mesh super absorbent The properties of the resin are shown in Table 1.

Embodiment 2

[0030] Mix 58.8g of deionized water and 1g of Tween 80, and stir for 15min at a stirring speed of 3000r / min;

[0031] Then add 1.5g of hydrogen peroxide, 5g of liquid paraffin, 30g of butyl oleate, 8g of dodecyl alcohol ester, 1g of Span 80, 0.8g of n-octanol and 5g of dimethicone and continue to stir evenly, stirring at a stirring speed of 2000r / min After 30 minutes, stop stirring and discharging to obtain the anti-sticking agent for super absorbent resin gel;

[0032] Pour the anti-adhesive agent into a watering can, spray 10g of anti-adhesive agent on the surface of 100g of super absorbent resin gel, cut into strips, extrude and granulate by screw, dry, pulverize and sieve to obtain 60-100 mesh super absorbent The properties of the resin are shown in Table 1.

Embodiment 3

[0034] Mix 62g of deionized water and 0.5g of Tween 80, and stir for 15min at a stirring speed of 3000r / min;

[0035] Then add 1g of hydrogen peroxide, 2g of liquid paraffin, 25g of butyl oleate, 6g of dodecyl alcohol ester, 0.7g of Span 80, 0.5g of n-octanol and 4g of dimethicone and continue to stir evenly, stirring at a stirring speed of 2000r / min After 25 minutes, stop stirring and discharging to obtain the anti-sticking agent for super absorbent resin gel;

[0036] Pour the anti-sticking agent into the watering can, spray 7g of the anti-sticking agent on the surface of 100g of super absorbent resin gel, cut into strips, extrude and granulate by screw, dry, pulverize and sieve to obtain 60-100 mesh super absorbent The properties of the resin are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com