Hydrophilic antibacterial water absorption material and preparation method thereof

A technology of wave-absorbing materials and antibacterial materials, applied in the field of coatings, can solve the problems of oil stains and food residues sticking, no easy-to-clean performance, and affecting applications, so as to achieve the effects of no health hazards, elimination of health hazards, and increased antibacterial function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

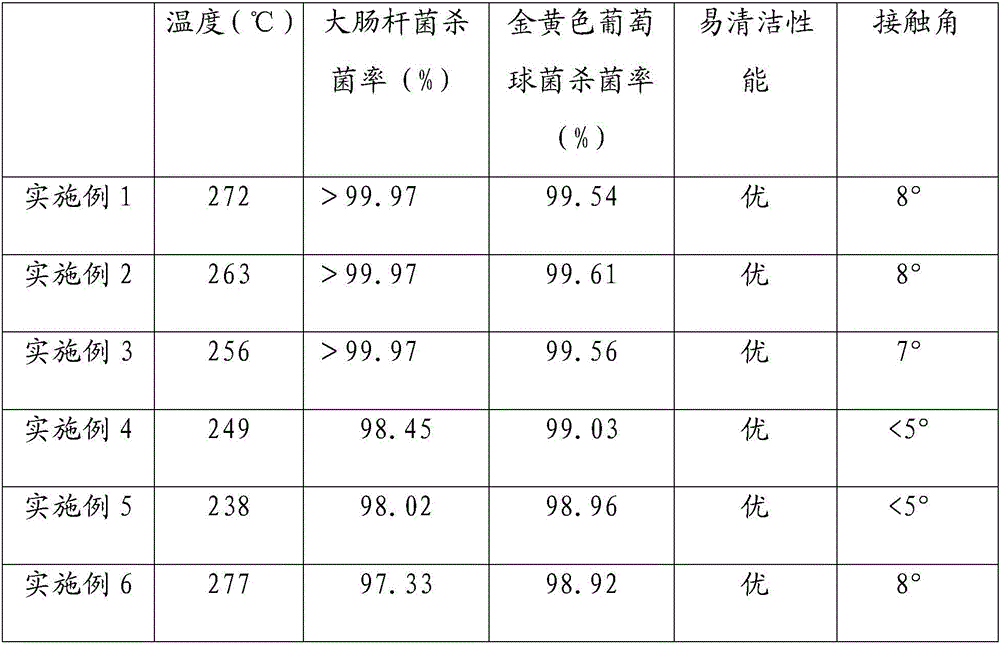

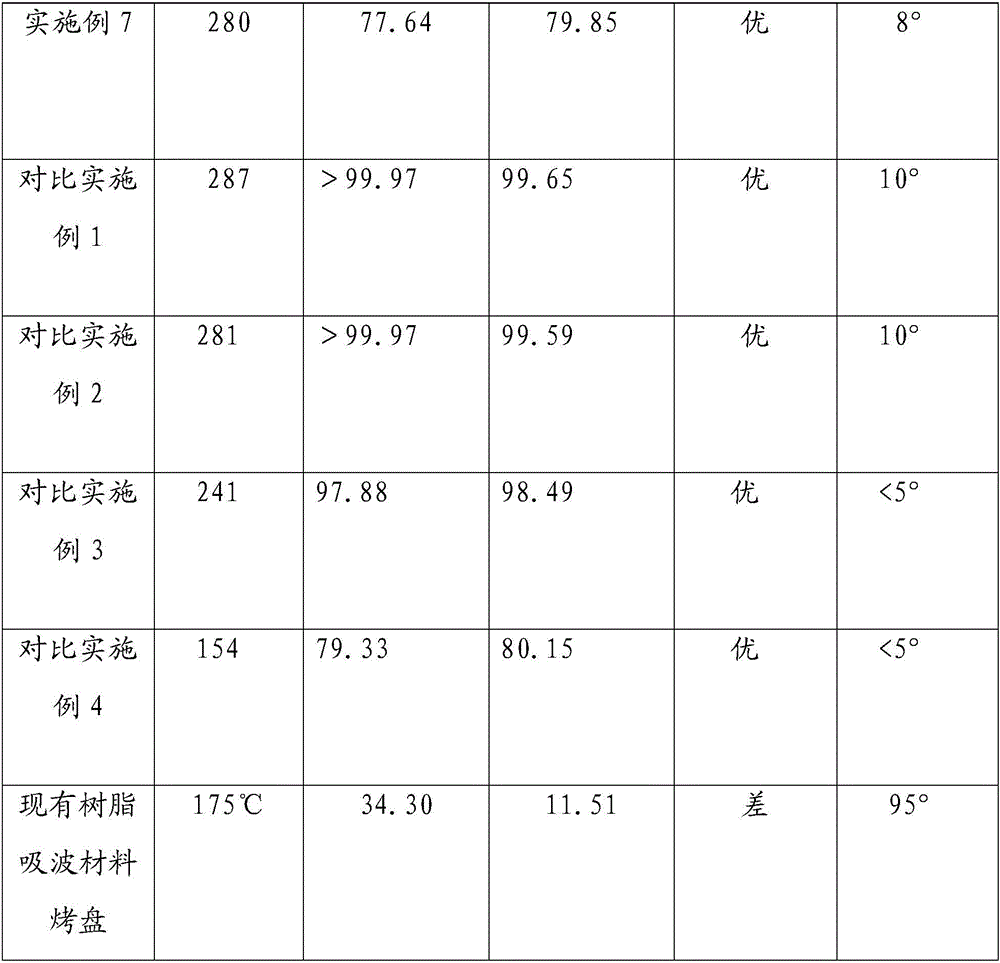

Examples

Embodiment 1

[0095] A hydrophilic antibacterial wave-absorbing material and its preparation method. The components of the coating are calculated by mass percentage, the inorganic binder of the wave-absorbing material is 90%, the wave-absorbing material is 7.7%, the antibacterial material is 0.8%, and the auxiliary agent 1.5%.

[0096] The preparation method is as follows:

[0097] 1) Preparation of antibacterial-adhesive mixed system:

[0098] Mix 50 kg of potassium silicate aqueous solution, 30 kg of sodium silicate aqueous solution, 10 kg of lithium silicate aqueous solution with 0.7 kg of coupling agent DN-8311W, stir mechanically at 400 r / min for 5 minutes, then add 0.1 kg of silver-phosphate, 0.2 kg Chitosan and 0.5 kilograms of nano-titanium dioxide continue to stir until uniformly mixed to obtain an antibacterial-adhesive mixed system;

[0099]2) Preparation of hydrophilic antibacterial absorbing material:

[0100] Add 5.9 kg of silicon carbide whiskers, 1.5 kg of graphene oxide,...

Embodiment 2

[0103] A hydrophilic antibacterial wave-absorbing material and its preparation method. The components of the coating are calculated by mass percentage, the inorganic binder of the wave-absorbing material is 92%, the wave-absorbing material is 5.8%, the antibacterial material is 1%, and the auxiliary agent was 1.2%.

[0104] The preparation method is as follows:

[0105] 1) Preparation of antibacterial-adhesive mixed system:

[0106] Mix 33 kg of potassium silicate aqueous solution, 51 kg of sodium silicate aqueous solution, 8 kg of lithium silicate aqueous solution with 0.6 kg of coupling agent DN-8311W, mechanically stir at 400 r / min for 5 minutes, then add 0.1 kg of silver-phosphate, 0.3 kg Chitosan and 0.6 kilograms of nano-titanium dioxide continue to stir until uniformly mixed to obtain an antibacterial-adhesive mixed system;

[0107] 2) Preparation of hydrophilic antibacterial absorbing material:

[0108] Add 4.5 kg of silicon carbide whiskers, 1.2 kg of graphene oxid...

Embodiment 3

[0111] A hydrophilic antibacterial wave-absorbing material and its preparation method. The components of the coating are calculated by mass percentage, the inorganic binder of the wave-absorbing material is 94%, the wave-absorbing material is 4.2%, the antibacterial material is 0.9%, and the auxiliary agent 0.9%.

[0112] The preparation method is as follows:

[0113] 1) Preparation of antibacterial-adhesive mixed system:

[0114] Mix 48 kg of potassium silicate aqueous solution, 30 kg of sodium silicate aqueous solution, 16 kg of lithium silicate aqueous solution with 0.4 kg of coupling agent DN-8311W, mechanically stir at 400 r / min for 5 minutes, then add 0.1 kg of silver-phosphate, 0.3 kg Chitosan and 0.5 kilograms of nano-titanium dioxide continue to stir until uniformly mixed to obtain an antibacterial-adhesive mixed system;

[0115] 2) Preparation of hydrophilic antibacterial absorbing material:

[0116] Add 3.2 kilograms of silicon carbide whiskers, 0.9 kilograms of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com