Preparation method of slow-release type multifunctional adhesive

An adhesive and multi-functional technology, applied in the direction of adhesives, non-polymer adhesive additives, aldehyde/ketone condensation polymer adhesives, etc., can solve the problems of anti-corrosion, anti-mold and less application of formaldehyde capture, and achieve broad market prospects and application value, improve anti-corrosion and anti-mildew, high-efficiency adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

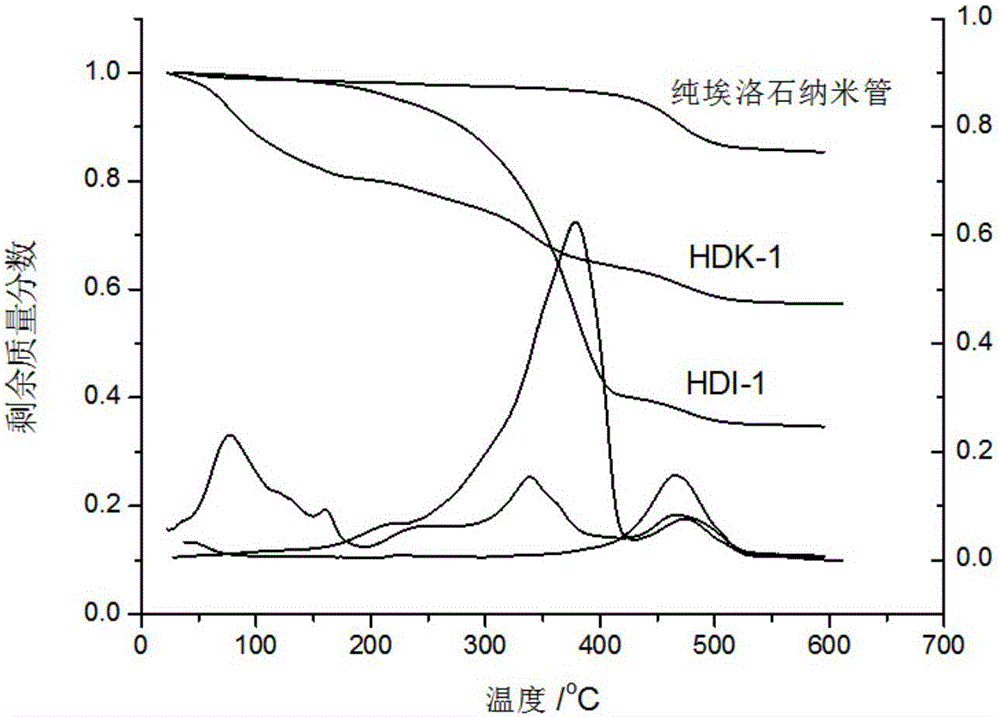

[0038] 1) Mix the halloysite nanotubes with distilled water at a mass ratio of 1:10, stir at 25°C for 8 hours, filter out the water, dry the halloysite nanotubes at 80°C and pulverize them evenly to obtain Treated halloysite nanotubes; adding the above-mentioned halloysite nanotubes into a mixed solvent with a mass ratio of 10:1 dimethyl sulfoxide and water, the treated halloysite nanotubes The mass ratio to the mixed solvent is 1:10, and the stirring activation reaction is carried out at 130°C for 3 hours. After the activation is completed, it is filtered, washed with water, dried, and pulverized to obtain the modified halloysite nanotubes for future use.

[0039] 2) The modified halloysite nanotubes and 3-iodo-2-propynyl butyl carbamate prepared above are added to ethanol together, and the modified halloysite nanotubes, 3-iodo-2- The mass ratio of propynyl butyl carbamate to ethanol is 1:2.5:15, sonicate at 40°C for 1 hour, then stir at room temperature for 12 hours, filter,...

Embodiment 2

[0043] 1) Mix the halloysite nanotubes with distilled water at a mass ratio of 1:5, stir at 45°C for 16 hours, filter out the water, dry the halloysite nanotubes at 65°C and pulverize them evenly to obtain Treated halloysite nanotubes; adding the above-mentioned halloysite nanotubes to a mass ratio of 9:1 acetonitrile and water mixed solvent, the treated halloysite nanotubes and mixed solvent The mass ratio is 1:12, and the stirring and activation reaction is carried out at 100°C for 24 hours. After the activation is completed, the modified halloysite nanotubes are obtained by filtering, washing with water, drying, and pulverizing.

[0044] 2) Add the modified halloysite nanotubes prepared above and 2,4,5,6-tetrachloro-1,3 phthalonitrile into dichloromethane, modify the halloysite nanotubes, 2, The mass ratio of 4,5,6-tetrachloro-1,3phthalonitrile to dichloromethane was 1:2:15, sonicated at 25°C for 1 hour, then stirred at room temperature for 16 hours, filtered, and dichlorom...

Embodiment 3

[0048] 1) Mix the halloysite nanotubes with distilled water at a mass ratio of 1:7, stir at 50°C for 10 hours, filter out the water, dry the halloysite nanotubes at 70°C and pulverize them evenly to obtain Treated halloysite nanotubes; adding the above-mentioned halloysite nanotubes into a mixed solvent with a mass ratio of 9:1 N-methylpyrrolidone and water, the treated halloysite nanotubes and The mass ratio of the mixed solvent is 1:10, and the stirring and activation reaction is carried out at 120°C for 6 hours. After the activation is completed, the modified halloysite nanotubes are obtained by filtering, washing with water, drying, and pulverizing.

[0049] 2) The above-mentioned modified halloysite nanotubes and propyl gallate were added to methanol together, the mass ratio of the modified halloysite nanotubes, propyl gallate and methanol was 1:3:20, at 30 Ultrasonic treatment at ℃ for 1 hour, followed by stirring at room temperature for 18 hours, filtering, fully rinsin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com