Pressurizing induction and pressurizing electroslag remelting duplex high-nitrogen steel smelting method

A pressurized induction and pressurized electroslag technology, applied in the field of high nitrogen steel smelting, can solve problems such as unstable nitrogen increase process, silicon increase in electroslag ingot, uneven nitrogen distribution in electroslag ingot, etc., to achieve low sulfur content, The effect of less non-metallic inclusions and uniform nitrogen distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

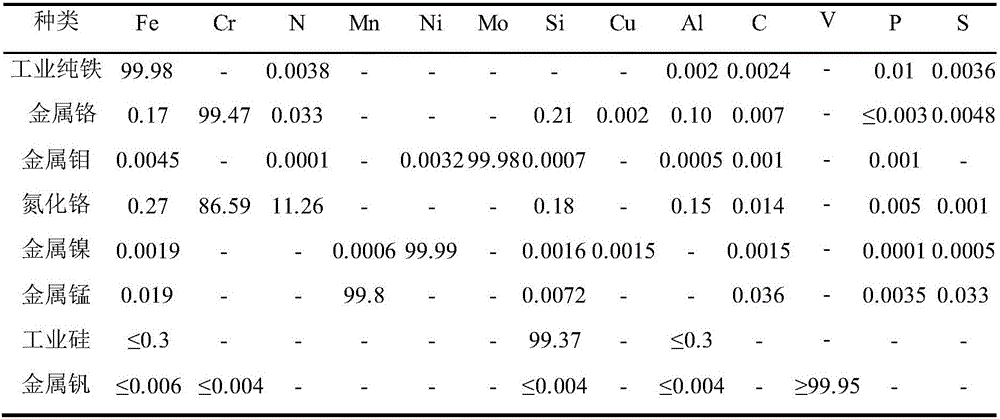

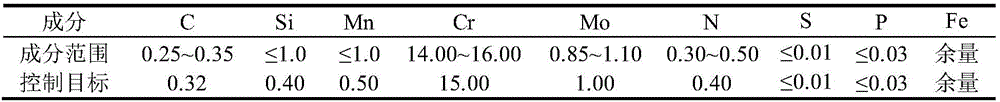

[0044] 21.0kg of the target steel grade high-nitrogen martensitic stainless steel 30Cr15MoN0.4 was smelted by pressure induction and pressure electroslag remelting double-linked process. The composition control range and smelting control target are shown in Table 2.

[0045] Table 2 30Cr15MoN0.4 composition control range and control target / wt.%

[0046]

[0047] Specific steps are as follows.

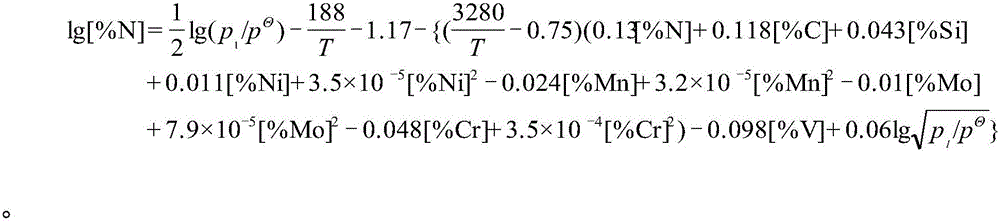

[0048] Pressure induction melting stage:

[0049] (1) Determination of ingredients and pressure parameters: According to the steel target composition in Table 2 and the smelting temperature of about 1550°C, it is calculated according to formula ① and formula ③: smelting pressure p 1 is 0.41MPa, casting pressure p 2 is 0.90MPa. The smelting raw materials and their quality are as follows: industrial pure iron 17241.9g, metal chromium 3176.36g, metal molybdenum 210.04g, metal manganese 112.91g, industrial silicon 70.51g, graphite 66.06g. Among them, graphite and industrial silicon a...

Embodiment 2

[0069] The 20.0kg target steel grade 50Cr17MoVN0.2 was smelted by the dual process of pressurized induction and pressurized electroslag remelting, and its composition control range and smelting control target are shown in Table 5.

[0070] Table 5 50Cr17MoVN0.2 composition control range and control target / wt%

[0071]

[0072] Specific steps are as follows.

[0073] Pressure induction melting stage:

[0074] (1) Determination of ingredients and pressure parameters: According to the steel target composition in Table 5 and the smelting temperature of about 1550°C, it is calculated according to formula ① and formula ③: smelting pressure p1 is 0.09MPa, casting pressure p 2 is 0.6MPa. The smelting raw materials and their quality are as follows: industrial pure iron 16048.5g, metal chromium 3428.46g, metal molybdenum 200.04g, metal manganese 96.78g, metal vanadium 20.01g, industrial silicon 74.52g, graphite 109.71g. Among them, graphite and industrial silicon are added 5.8% an...

Embodiment 3

[0094] 20.5 kg of the target steel grade 18Cr14Mn3Mo0.9N was smelted by the dual process of pressurized induction and pressurized electroslag remelting, and its composition control range and smelting control target are shown in Table 8.

[0095] Table 8 18Cr14Mn3Mo0.9N composition control range and control target / wt%

[0096]

[0097]

[0098] Specific steps are as follows.

[0099] Pressure induction melting stage:

[0100] (1) Determination of ingredients and pressure parameters: According to the steel target composition in Table 2 and the smelting temperature of about 1550°C, it is calculated according to formula ① and formula ②: smelting pressure p 1 0.25MPa, casting pressure p 2 is 1.0MPa. The actual weight percentage of nitrogen content in smelting raw materials (wt) 1 The smelting raw materials and their quality are as follows: industrial pure iron 13684.8g, metal chromium 2746.09g, metal molybdenum 758.65g, metal manganese 3196g, chromium nitride 1116g, indus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com