Method for recycling lead bullion from lead copper matte

A technology of lead matte and crude lead, which is applied in the field of recovering crude lead from lead matte, can solve the problems of low recovery rate of valence metals, and achieve the effects of high lead content, short processing time and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The raw material lead matte used in this embodiment is a by-product of pyrometallurgy, and its main chemical composition is: Pb (43.23%), Cu (12.13%), Fe (12.78%), Zn (8.87%) and S (18.35%) %).

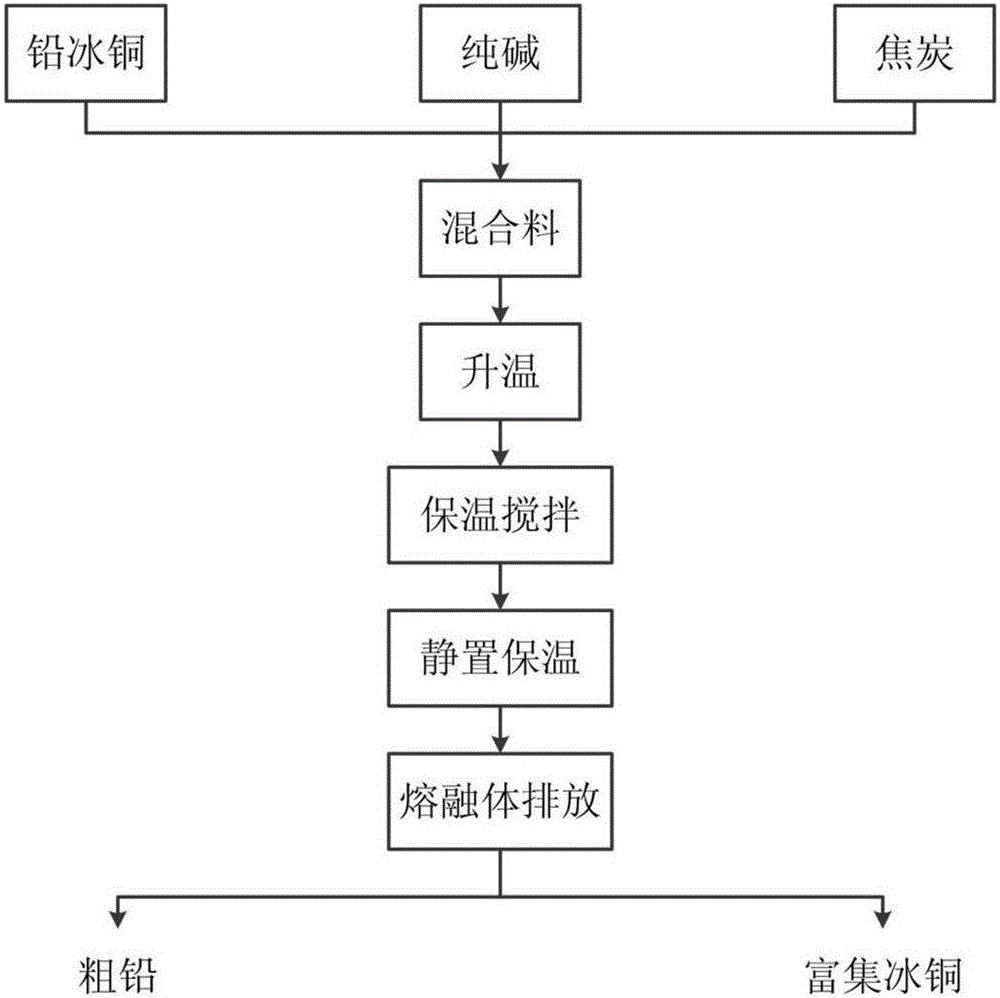

[0033] A kind of embodiment of the method that the present invention reclaims crude lead from lead matte, its technological process is as figure 1 As shown, it mainly includes the following steps:

[0034] (1) Use a crusher to crush 5050g of lead matte to a particle size of 3-7cm.

[0035] (2) According to the mass ratio of lead matte, soda ash and coke of 100:6:11, weigh the soda ash and coke and mix them with the crushed lead matte to obtain a mixture.

[0036] (3) Put the obtained mixture in a smelting furnace, raise the temperature of the furnace to 1100° C., and gradually melt the lead matte and become a melt.

[0037] (4) After the lead matte is completely melted, use an iron stirring tool to carry out intermittent heat preservation and stirring at 1100°C. Stir 4 time...

Embodiment 2

[0042] The raw material lead matte used in this embodiment is a by-product of pyrometallurgy, and its main chemical composition is: Pb (41.35%), Cu (11.83%), Fe (13.32%), Zn (8.03%) and S (17.18%) %).

[0043] A kind of embodiment of the method that the present invention reclaims crude lead from lead matte, its technological process is as figure 1 As shown, it mainly includes the following steps:

[0044] (1) Use a crusher to crush 4980 g of lead matte to a particle size of 4 to 8 cm.

[0045] (2) According to the mass ratio of lead matte, soda ash and coke of 100:7:9, weigh soda ash and coke and mix them with the crushed lead matte to obtain a mixture.

[0046] (3) Put the obtained mixture in a smelting furnace, raise the temperature of the furnace to 1300°C, and gradually melt the lead matte and become a melt.

[0047] (4) After the lead matte is completely melted, use an iron stirring tool to carry out intermittent heat preservation and stirring at 1300°C. A total of 2 ...

Embodiment 3

[0052] The raw material lead matte used in this embodiment is a by-product of pyrometallurgy, and its main chemical composition is: Pb (42.28%), Cu (12.11%), Fe (13.69%), Zn (9.01%) and S (18.24%) %).

[0053] A kind of embodiment of the method that the present invention reclaims crude lead from lead matte, its technological process is as figure 1 As shown, it mainly includes the following steps:

[0054] (1) Use a crusher to crush 4916g of lead matte to a particle size of 1-6cm.

[0055] (2) According to the mass ratio of lead matte, soda ash and coke of 100:5:12, weigh the soda ash and coke and mix with the crushed lead matte to obtain a mixture.

[0056] (3) Put the obtained mixture in a smelting furnace, raise the temperature of the furnace to 1100° C., and gradually melt the lead matte and become a melt.

[0057] (4) After the lead matte is completely melted, use an iron stirring tool to carry out intermittent heat preservation and stirring at 1100°C. A total of 6 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com