Underground blind ditch drainage system

A technology of drainage system and blind ditch, which is used in construction, road bottom, infrastructure engineering, etc., can solve the problems of large design flow, low effective drainage area ratio, and high engineering cost, and achieve large drainage section, good drainage effect, and prevent Blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

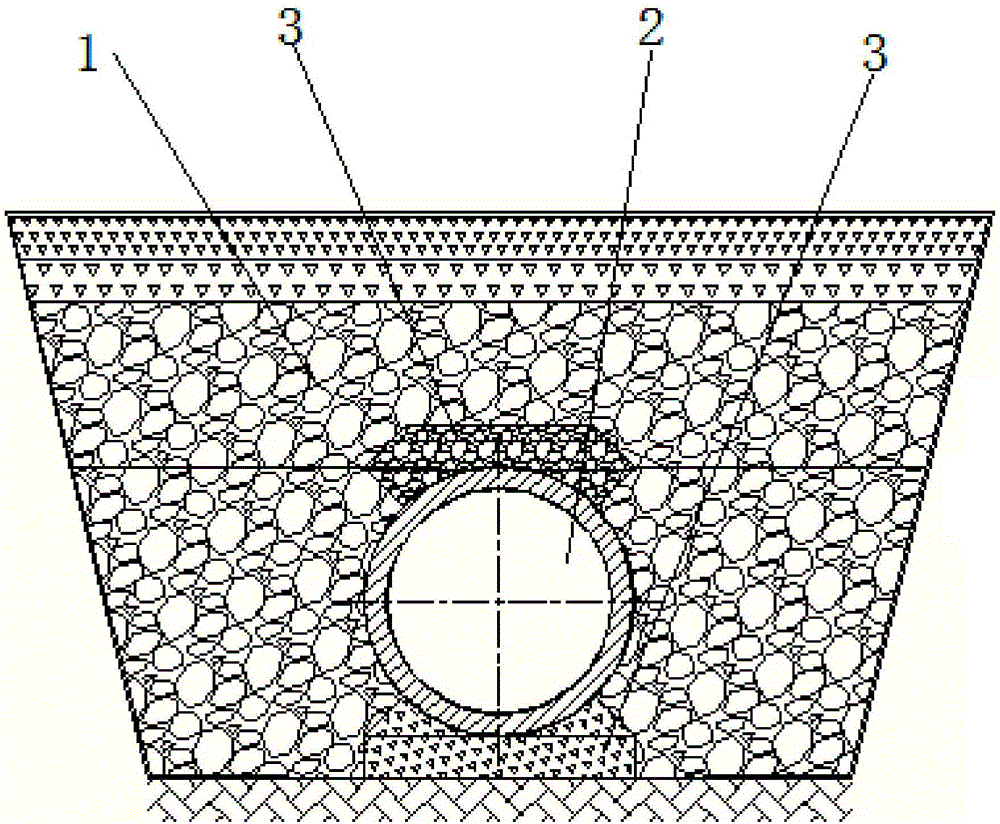

[0020] like figure 1 As shown, the underground blind ditch drainage system of the present invention includes an underground block gravel blind ditch 1, a reinforced concrete drainage culvert 2 located in the underground block gravel blind ditch 1, and the bottom and top of the drainage culvert 2 are respectively arranged There is a stress-regulating cushion 3; the drainage culvert 2 is composed of multi-section culverts, gaps are left between adjacent culverts, and adjacent culverts are connected by a permeable geotextile wrapped with a geogrid.

[0021] The inner diameter of the drainage culvert is 600mm-800mm, and the wall thickness is 80-100mm. The length of each section of culvert is 1.5-3.0m. The principle is to facilitate transportation and hoisting. The gap between adjacent culverts is 10cm. In order to ensure smooth water flow between the culvert pipe and the gravel blind ditch on the outside of the culvert pipe, and at the same time facilitate the wrapping connecti...

Embodiment 2

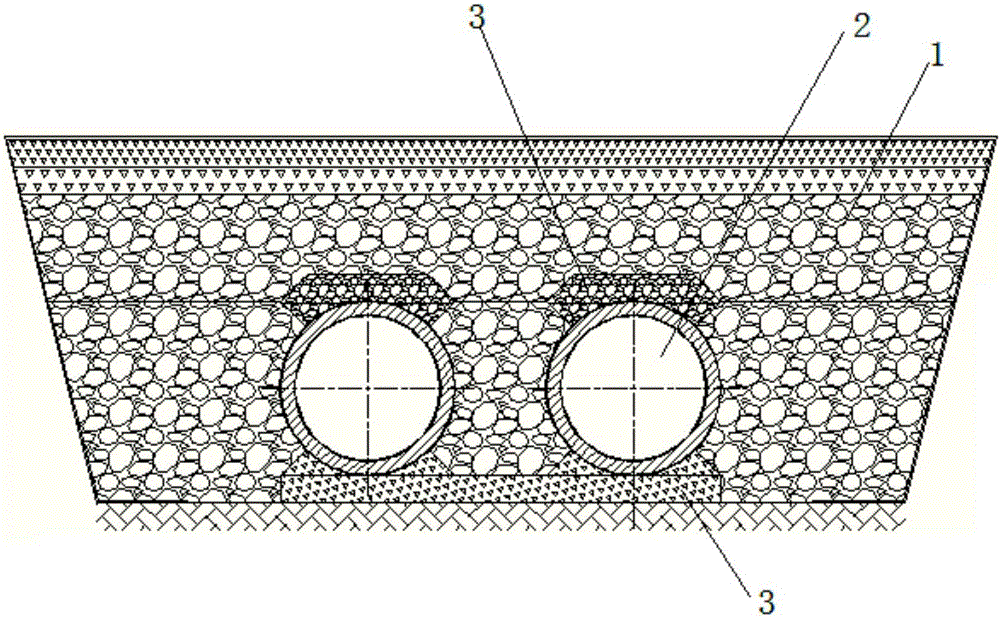

[0023] like figure 2 As shown, the underground blind ditch drainage system of this embodiment has the same basic structure and principle as that of Embodiment 1, except that there are two drainage culverts, and the clear distance between the drainage culverts is greater than 0.5m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com