A proportional control device and control method for a cable winch with closed-loop feedback

A proportional control and closed-loop feedback technology, which is applied to valve devices, fluid pressure actuators, mechanical equipment, etc., can solve the problems of low control precision, achieve high control precision, high controllability, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

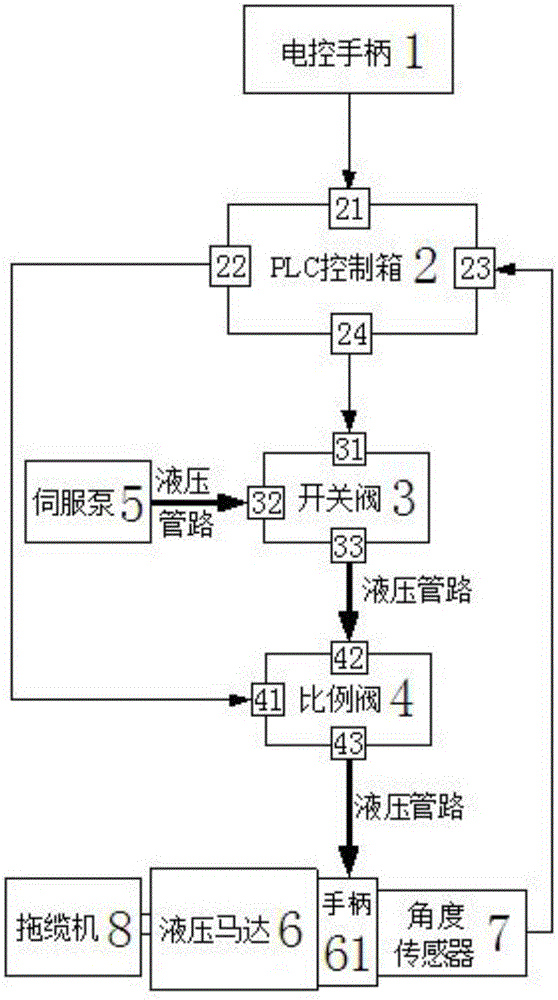

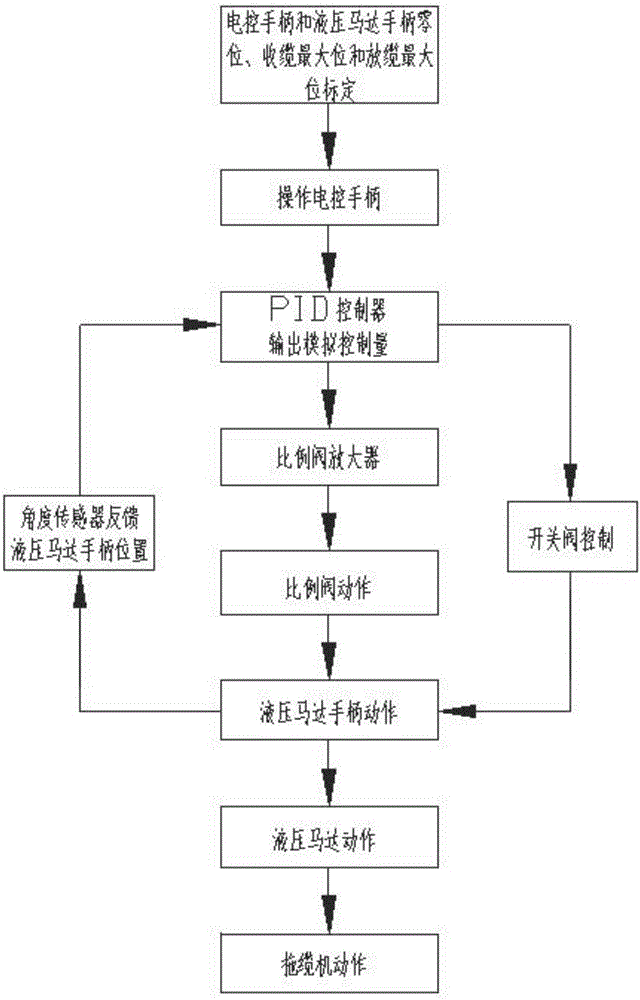

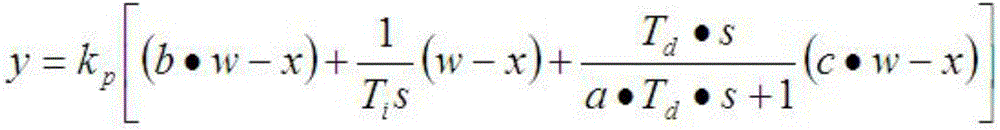

[0055] A kind of proportional control device of the towing machine with closed-loop feedback, comprising an electric control handle 1 and a PLC control box 2, the signal output end of the electric control handle 1 is connected with the control signal input end 21 of the PLC control box 2; The proportional control device of the towing machine also includes an on-off valve 3, a proportional valve 4, a servo pump 5, a hydraulic motor 6 and an angle sensor 7; Electrically connected, the proportional signal output end 22 of the PLC control box 2 is electrically connected to the proportional signal control end 41 of the proportional valve 4; the servo pump 5 passes through the switch valve 3, the proportional valve 4 and the motor handle 61 of the hydraulic motor 6 The oil inlet port of the motor is connected to the oil circuit, the motor handle 61 is provided with an angle sensor 7, and the signal output end of the angle sensor 7 is electrically connected with the feedback signal in...

Embodiment 2

[0069] Embodiment 2 is basically the same as Embodiment 1 and its difference is:

[0070] The control method also includes:

[0071] Step 5: Stop and return to the original position. When the electric control handle 1 is pulled back to the middle position, the value of the control signal input value w of the PLC control box 2 is 0, and the switch signal output terminal 24 of the PLC control box 2 jumps to a low potential , the switch signal control terminal 31 is powered off, the control switch valve 3 is closed, and at the same time the proportional valve output control value y is forced to zero, the proportional valve 4 is closed, the oil circuit is closed at this time, and the motor handle 61 quickly returns to the middle position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com