A step-variable permanent magnet rheological damper

A damper and permanent magnet technology, applied in the field of step-variable permanent magnet rheological dampers, can solve the problems of high system design cost, limited application environment, and low collection energy, and achieve low cost, simple structure design, and application stability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

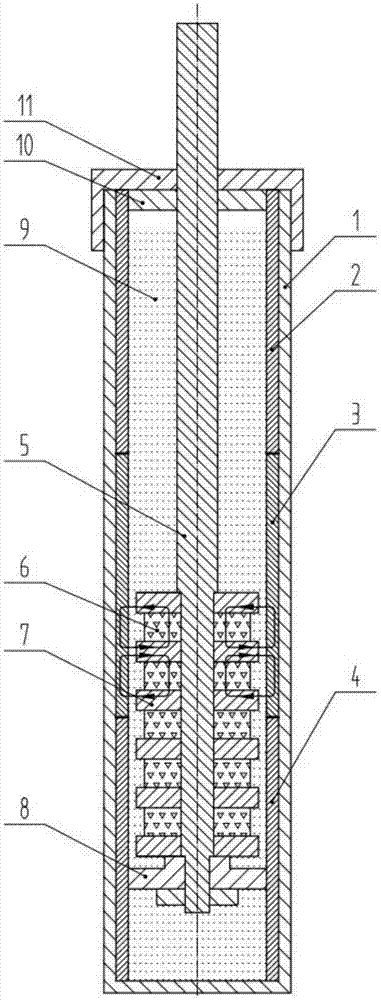

[0014] figure 1 It is a schematic diagram of the structure of the present invention. The present invention is a step-change permanent magnet rheological damper, comprising an outer cylinder 1, an inner cylinder 2, an inner cylinder 2 3, an inner cylinder 3 4, a piston rod 5, A number of permanent magnets 6, a number of magnetic blocks 7, a guide device 8, a magneto-rheological fluid 9, a sealing ring 10, and an end cover 11. The outer cylinder 1, the inner cylinder 1 2 and the inner cylinder 3 4 are all made of aluminum alloy, the inner cylinder 2 3 is electric pure iron DT4, the inner cylinder 1 2, the inner cylinder 2 3 and the inner cylinder 3 4 Quantitative magnetorheological fluid 9 is distributed inside. The shaft diameter at one end of the piston rod 5 is small, and several magnetic blocks 7 with inner holes and several permanent magnets 6 are sequentially installed on it to form a piston structure. Each adjacent permanent magnet 6 adopts the magnetic pole of the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com