Separation tower resin interface intelligent monitoring system and high-tower method resin analysis method

A resin interface, intelligent monitoring technology, applied in the separation tower resin interface intelligent monitoring system, thermal power water treatment environmental protection equipment, nuclear power fields, can solve the problems of large maintenance and repair, detection sensitivity and stability impact, complex laser sensor circuit and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

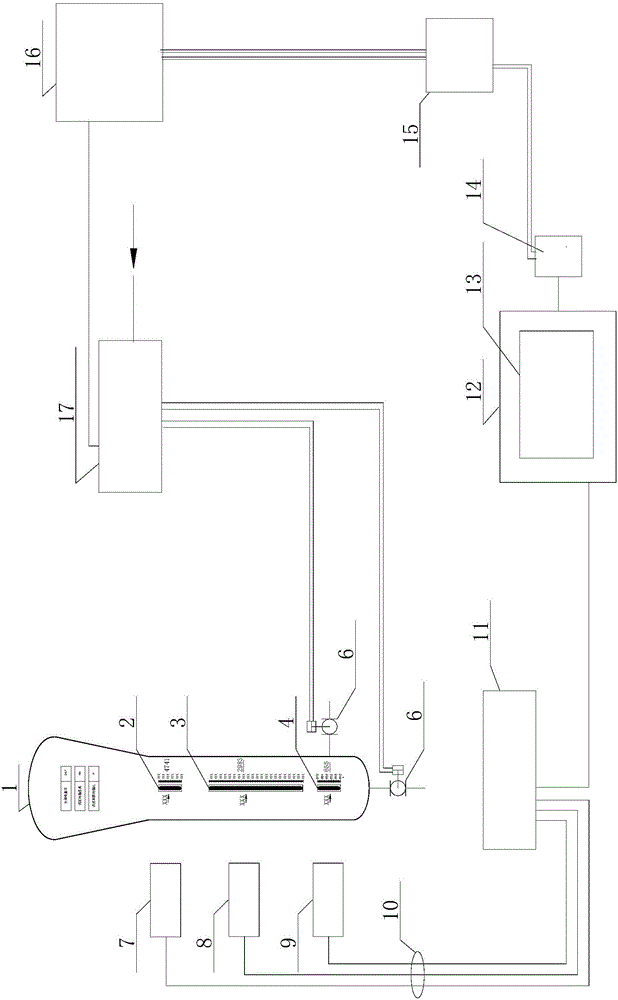

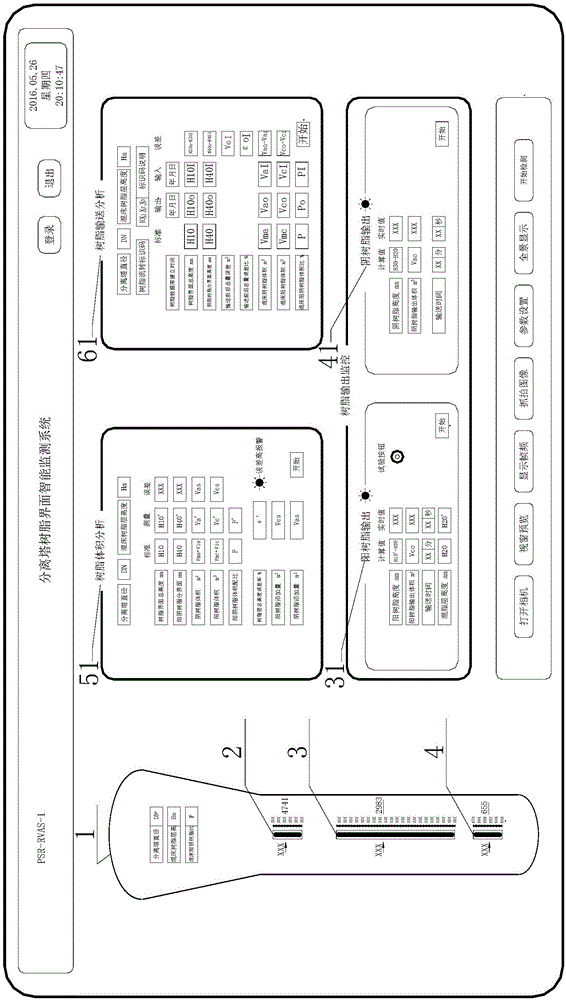

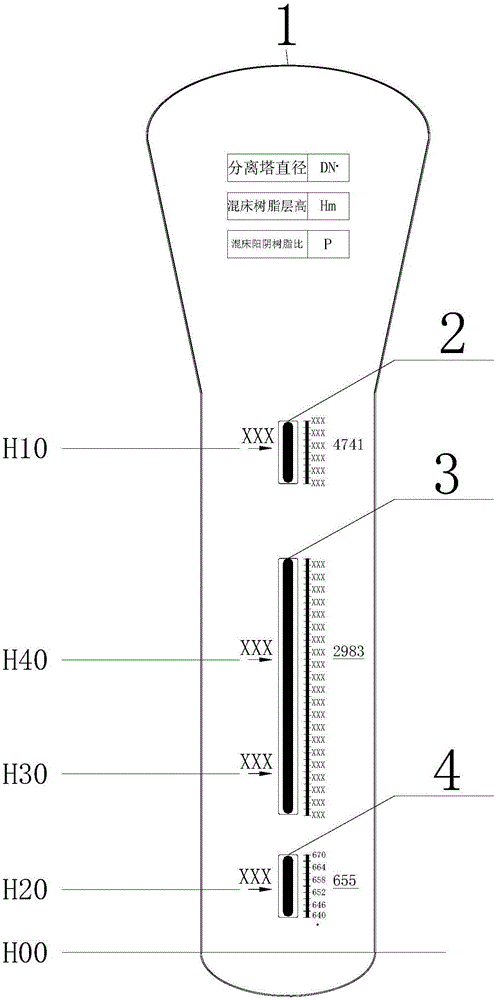

[0100] refer to figure 1 , figure 2 and image 3 , a specific implementation of the separation tower resin interface intelligent monitoring system and high tower method resin analysis method of the present invention is:

[0101] The bottom of the separation tower is connected to the positive resin outlet door; the lower side of the separation tower is connected to the anion resin outlet door, and the interface position is the distance between the center of the connection flange of the anion resin outlet door, which is D / 2 at the height of the interface between the water and the mixed fat after the anion resin is sent out. D is the inner diameter of the pipe connecting the anion resin outlet door and the separation tower; the horizontal distance between the upper, middle and lower window cameras and the upper, middle and lower windows is adjustable from 0.1 to 5m; each camera is connected to the monitoring computer; the monitoring computer is installed with Windows and Window...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com