Yellow light absorption structure and backlight module having the same

A technology of absorbing structure and backlight module, applied in the field of materials, can solve the problem of color shift of display screen, and achieve the effect of maintaining color white balance, reducing color shift and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

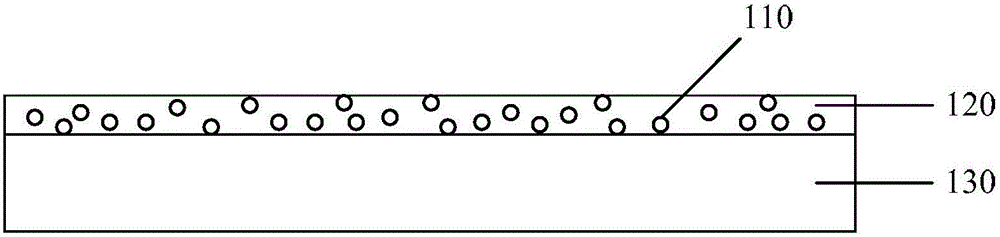

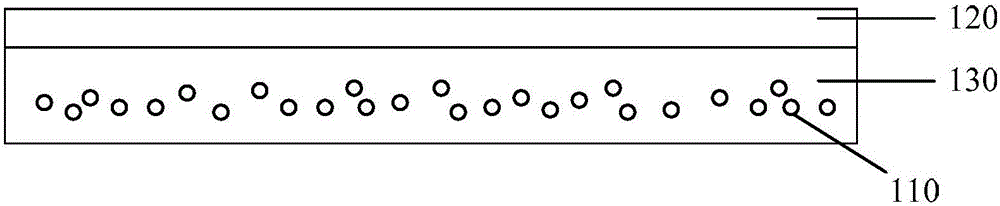

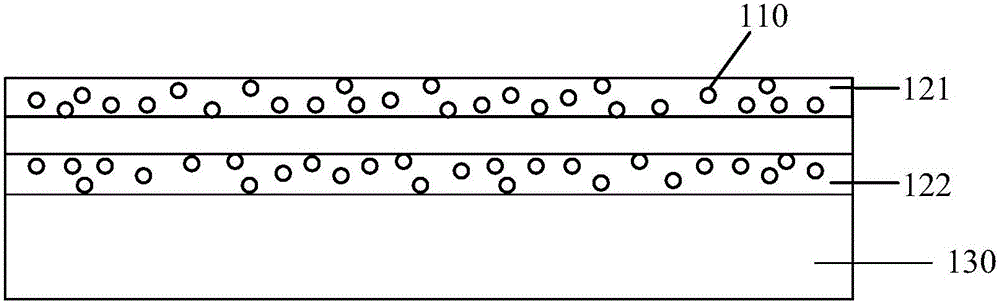

[0047] The method for preparing the yellow light absorbing structure described above may include the following steps: an anti-blue light film layer 120 is disposed on the base 130, and a yellow light absorbing material 110 is disposed in the base 130 or the blue light resistant film 120. Since the yellow light absorbing structure is provided with the anti-blue film layer 120 and the yellow light absorbing material 110, when the yellow light absorbing structure is integrated into the display module, the yellow light absorbing structure can not only be used to filter the harmful effects to human eyes The blue light band, thereby reducing the damage of the display screen to the human eye, can also absorb part of the yellow light band to reduce the color shift of the display screen and maintain the color white balance of the display screen.

[0048] When the anti-blue light film layer 120 includes multiple anti-blue light refraction layers, the step of disposing the anti-blue light fi...

Embodiment 1

[0058] The method for preparing the yellow light absorbing structure provided in this embodiment includes the following steps:

[0059] SiO with a thickness of 33nm is sequentially formed on the PET substrate by sputtering process 2 (Refractive index of 1.539), Cr with a thickness of 5nm (refractive index of 1.98), SiO with a thickness of 735nm 2 (Refractive index is 1.539), Nb with a thickness of 6.8nm 2 O 5 (Refractive index 2.459) and SiO with a thickness of 274nm 2 (The refractive index is 1.539) to form a multi-layer anti-blue reflection layer. Both the top anti-blue refraction layer and the bottom anti-blue refraction layer are provided with yellow light absorbing materials. The yellow light absorbing material is a metalloporphyrin compound, the model is ABS584 , The manufacturer is Exciton, USA.

Embodiment 2

[0061] The method for preparing the yellow light absorbing structure provided in this embodiment includes the following steps:

[0062] Step A, mixing and diluting 40% by weight of blue light absorbing material, 50% by weight of yellow light absorbing material and 54.8% by weight of oligomer, stirring for 1 hour to form anti-blue light coating, among which, blue light The model of the absorbing material is ABS430, the manufacturer is EXCITON, the yellow light absorbing material is a metalloporphyrin compound, the model is ABS574, the manufacturer is Exciton, the oligomer is polyurethane, the model is EB8415;

[0063] In step B, the anti-blue light coating is coated on a 100um PET substrate by using the No. 7 wire rod of RDS in the United States, and the anti-blue light coating is cured by heat treatment to form an anti-blue light film layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com