Neodymium-iron-boron permanent magnet wave-absorbing material and preparing method thereof

A wave absorbing material, NdFeB technology, applied in the direction of magnetic material, inorganic material magnetism, magnetic object, etc., can solve the problems of narrow effective frequency band, thick matching thickness, low saturation magnetization of ferrite, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

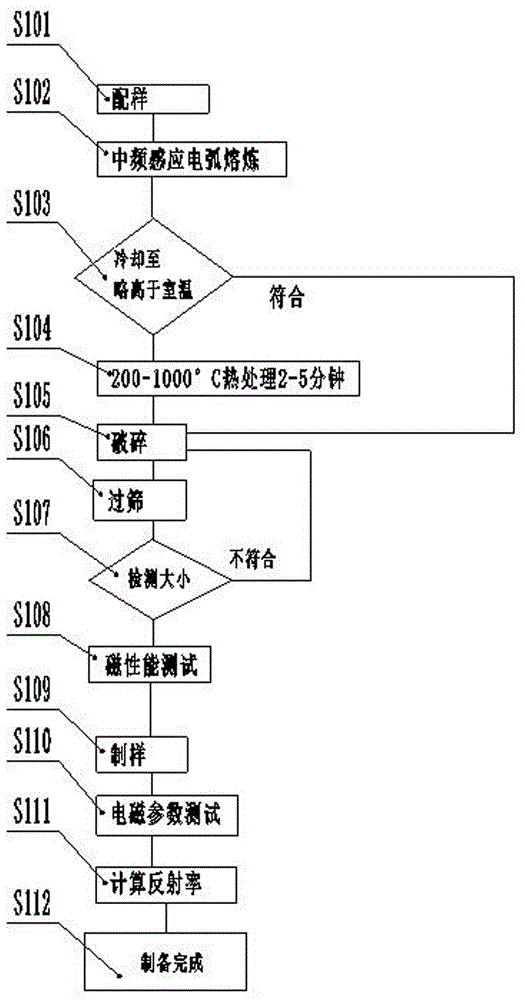

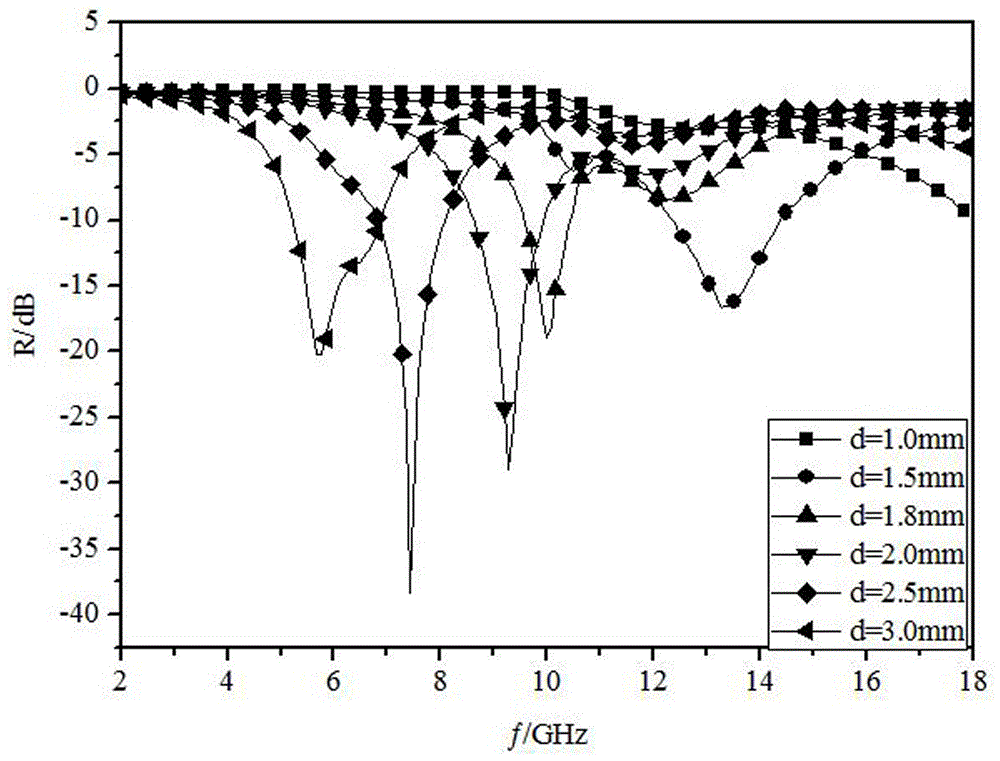

[0042] Preparation (PrNd) 28.0 Gd 1.2 Nb0.2 Dy 0.5 Ho 0.1 Fe 67.4 al 0.5 Cu 0.5 co 0.6 B 1.0 , the preparation method comprises the following steps:

[0043] 1) Ingredients: PrNd, ZrFe, NbFe, BFe, HoFe, GdFe, Co, Al, Cu, Fe with purity ≥99.90% as raw materials, according to PrNd: 26.2-30%, ZrFe: 0.35-0.6%, NbFe: 0.2 ~0.6%, BFe: 5~5.5%, HoFe: 4.5~5.5%, GdFe: 2.1~2.6%, Co: 0.2~0.7%, Al: 0.5~0.65, Cu: 0.11~0.21%, Fe: 58.9~60.87% Stoichiometric formulation of atomic percentages;

[0044] 2) Melting the ingredients in step 1) in an intermediate frequency induction furnace;

[0045] 3) performing quick-setting pouring on the solution smelted in step 2), to obtain quick-setting cast strips;

[0046] 4) take out after cooling the quick-setting strip sheet in step 3);

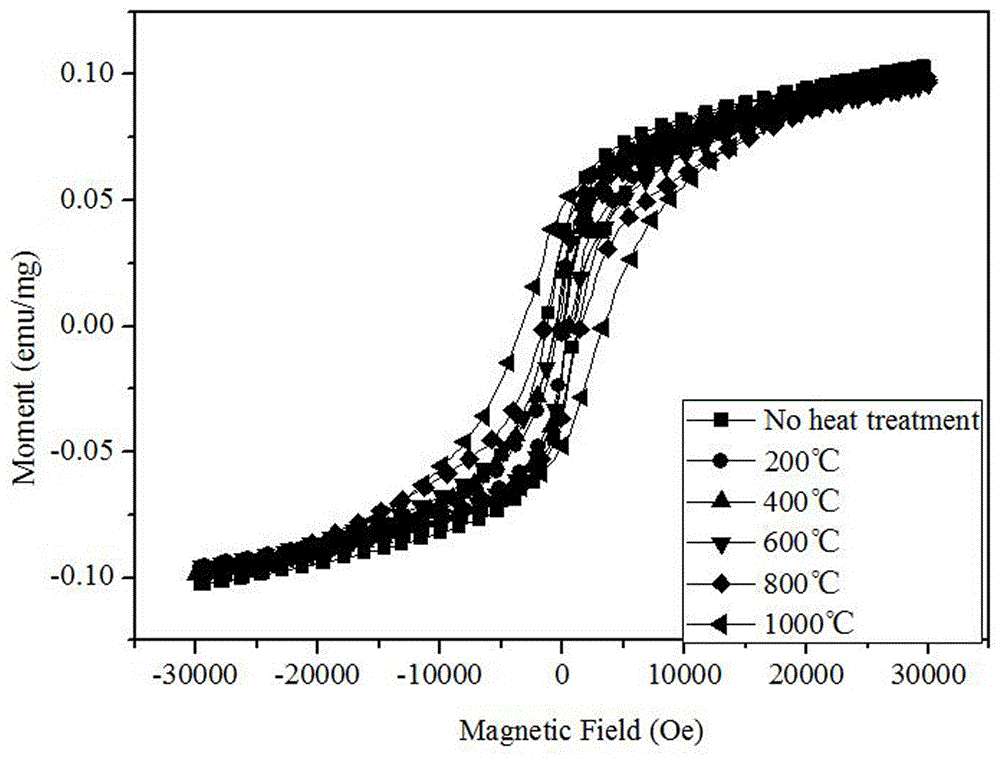

[0047] 5) Step 4) heat-treat the cooled quick-setting fling strip sheet at room temperature to 1000°C;

[0048] 6) breaking the quick-setting strip sheet after heat treatment in step 5);

[0049] 7) sieve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com