Inkjet printing preparation method of thin film, and preparation method of thin film transistor

An inkjet printing and thin film technology, applied in the direction of transistors, electrical solid state devices, semiconductor devices, etc., can solve the problems of increasing process complexity and cost, and achieve the effect of good uniformity and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

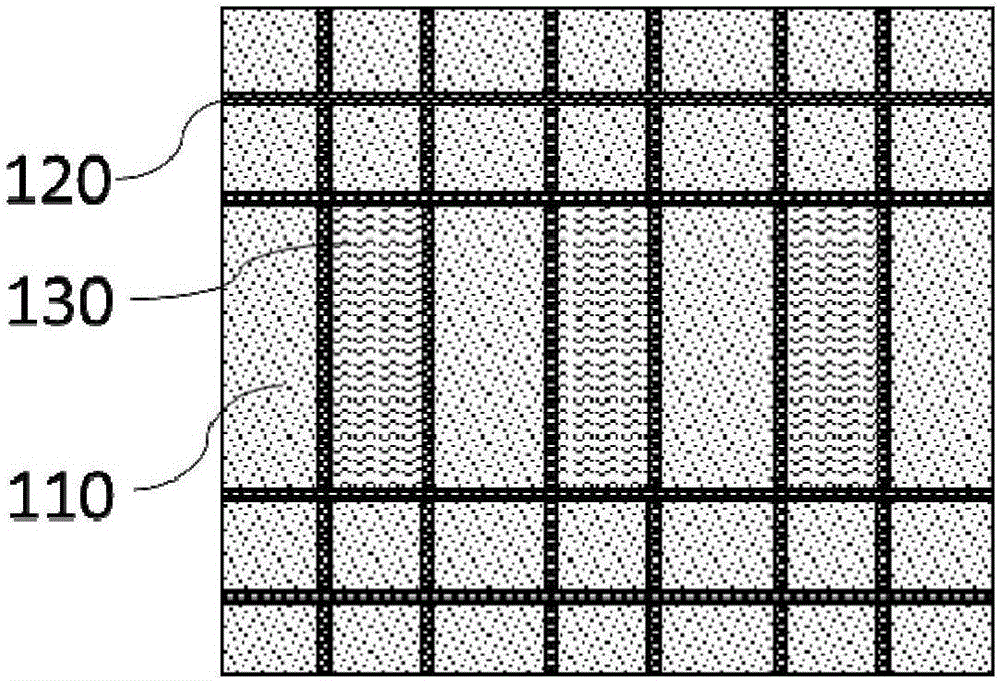

[0048] Provided is an ink-jet printing preparation method of a film, in which the shape of the ink-jet printed film is defined by a hydrophobic coffee ring grid. The shape of the film includes a film pattern, a film size, a film thickness, or a film shape.

[0049] The ink-jet printing preparation method of film, comprises the steps:

[0050] a. Preparation of the coffee ring mesh.

[0051] The coffee ring mesh is a hydrophobic polymer coffee ring mesh. The preparation of the coffee ring grid is specifically to inkjet print a hydrophobic line grid with obvious coffee rings on the substrate, and then perform plasma treatment and annealing to obtain the coffee ring grid. The material of the hydrophobic wire mesh can be fluororesin CYTOP, polytetrafluoroethylene (PTFE) or polystyrene (PS).

[0052] b. Spray the ink droplet directly into the grid unit of the coffee ring, dry and post-anneal to obtain a solid film. By adjusting the number of inkjet droplets and ink concentratio...

Embodiment 2

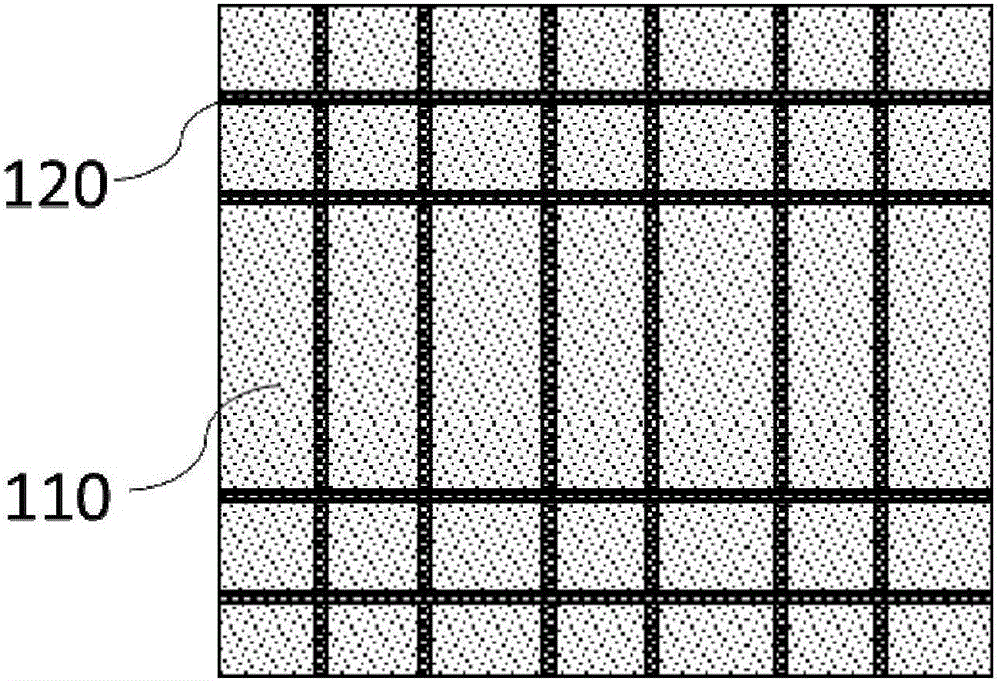

[0062] Provided is an ink-jet printing preparation method of a film, in which the shape of the ink-jet printed film is defined by a hydrophobic coffee ring grid. The shape of the film includes a film pattern, a film size, a film thickness, or a film shape.

[0063] The ink-jet printing preparation method of film, comprises the steps:

[0064] a. Preparation of the coffee ring mesh.

[0065] The coffee ring mesh consists of a lower hydrophilic polymer layer and an upper hydrophobic polymer layer.

[0066] The preparation of the coffee ring grid specifically includes:

[0067] a1. Prepare a hydrophilic polymer layer and anneal on the substrate by methods such as spin coating, pulling, spraying or printing; the material as the hydrophilic polymer layer is polyvinyl alcohol (PVA), polyvinylpyrrolidone (PVP) or polyvinyl Acrylic acid (PAA);

[0068] a2. Re-inkjet printing a hydrophobic line grid with obvious coffee rings; the material of the hydrophobic line grid is fluororesin...

Embodiment 3

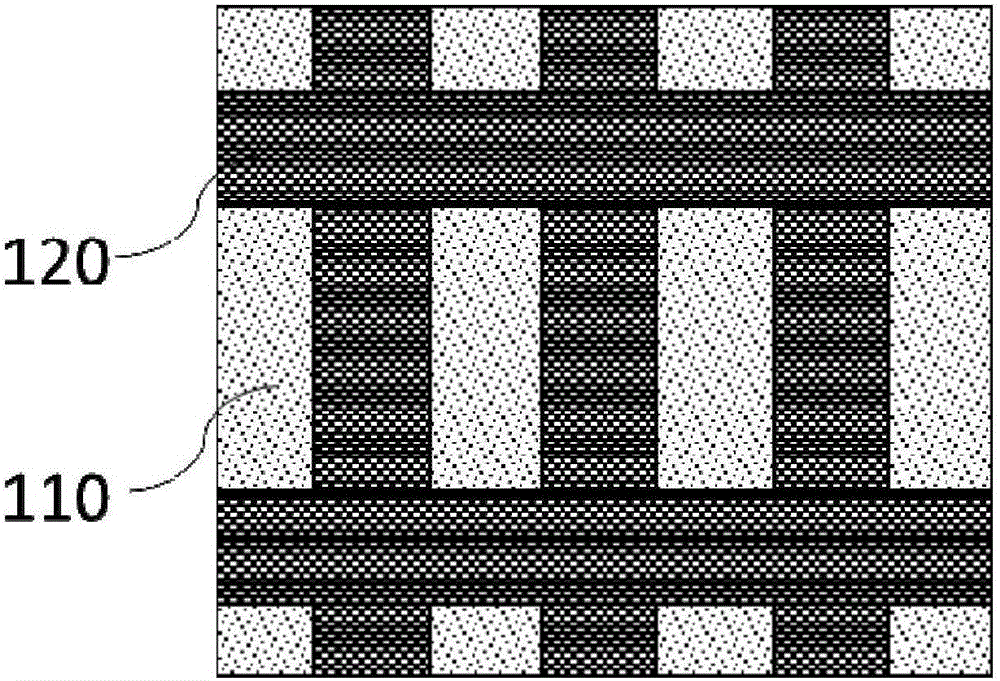

[0080] This embodiment provides a CYTOP coffee ring grid to define an indium oxide thin film pattern.

[0081] The preparation method of CYTOP coffee ring mesh is as follows:

[0082] Inkjet printing of CYTOP line grids on Al2O3 substrates. The CYTOP line width is 80um, the row spacing of the grid is set to 160um, and the column spacing is set to 320um. The printed CYTOP has obvious coffee rings.

[0083] Use oxygen plasma to treat the Al2O3 printed with CYTOP line grid, the power is 30W, and the time is 3min, leaving the CYTOP coffee ring grid, and the CYTOP coffee ring grid after plasma treatment is annealed at 120°C for 10min.

[0084] The indium oxide precursor ink was inkjet printed in the CYTOP coffee ring grid unit, the ink concentration was 0.1M, and the ink volume in each unit was the same.

[0085] The indium oxide ink in the CYTOP coffee ring grid unit is dried at 50°C for 5 minutes and annealed at 350°C for 1 hour to form an indium oxide film. The morphology of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com