Secondary dry etching method based on nanoimprint grating and epitaxial wafer and laser

A technology of nanoimprinting and dry etching, which is applied to the structure of optical resonant cavities, etc., can solve problems such as the large influence of grating etching morphology, threshold current, optical power influence, and difficulty in obtaining grating morphology. Achieve the effect of excellent grating shape, small emission spectral bandwidth and good depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

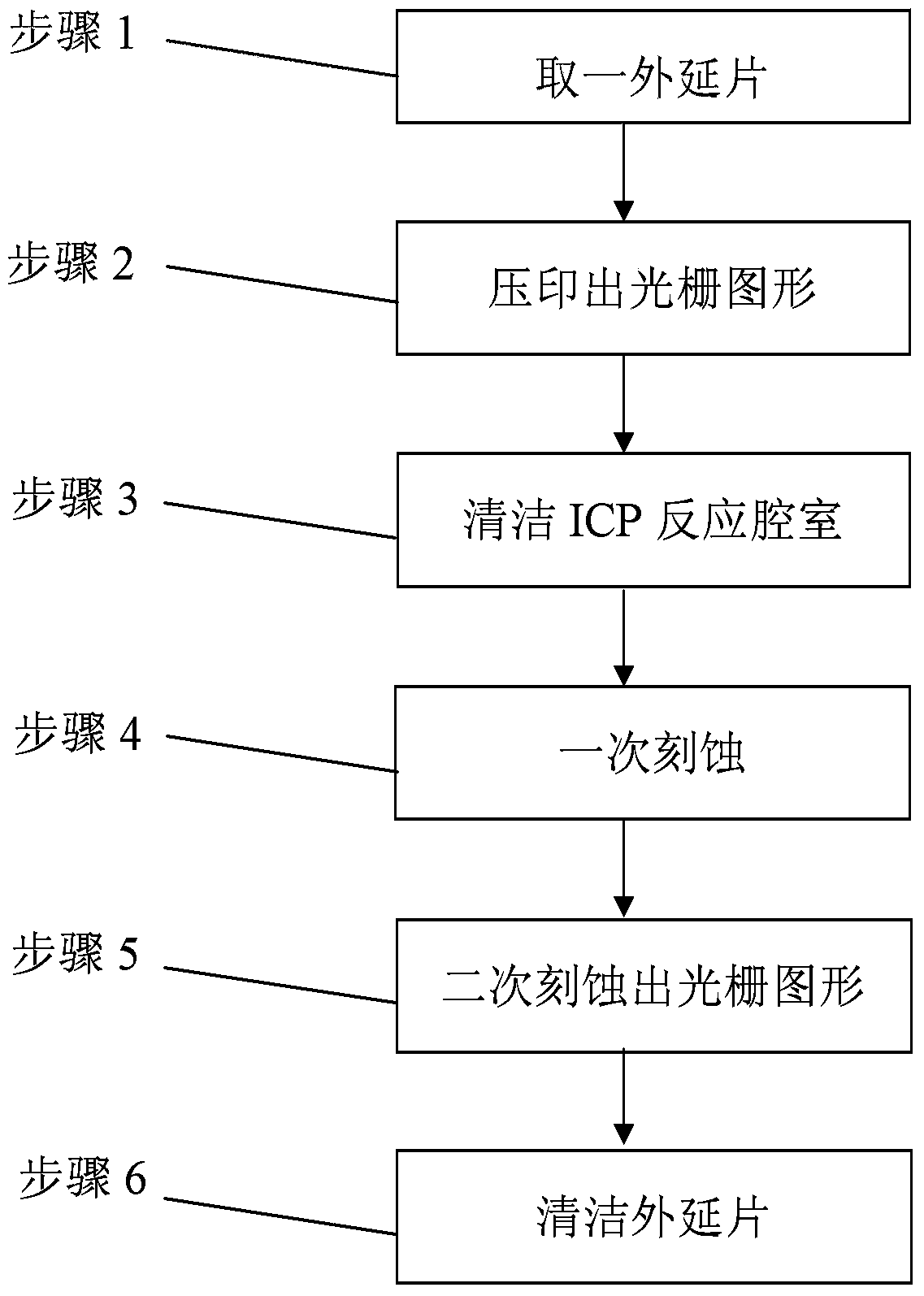

[0030] The secondary dry etching method based on the nanoimprint grating of the present invention, such as figure 1 shown, including the following steps:

[0031] Step 1: Take an epitaxial wafer that has completed one epitaxy, the material of the grating layer is GaInP, and the thickness is about 200nm.

[0032] Step 2: transferring the nanometer pattern on the imprint template to the photoresist coated on the surface of the epitaxial wafer to produce a grating pattern.

[0033] Step 3: Clean the inductively coupled plasma (ICP) reaction chamber to ensure that the chamber is clean and free from contamination. use 2 and SF 6 Mixed gas treatment for 3 minutes, and then O 2 Treatment for 3 minutes is mainly to remove residual organic polymer contamination in the ICP reaction chamber. The cleaning procedure uses 100W of RF power and 1500W of inductively coupled power.

[0034] Step 4: Send the epitaxial wafer with the imprinted grating pattern into the ICP reaction chamber f...

Embodiment 2

[0045] The secondary dry etching method based on the nanoimprint grating of the present invention, such as figure 1 shown, including the following steps:

[0046] Step 1: Take an epitaxial wafer that has completed one epitaxy, the material of the grating layer is GaInP, and the thickness is about 200nm.

[0047] Step 2: transferring the nanometer pattern on the imprint template to the photoresist coated on the surface of the epitaxial wafer to produce a grating pattern.

[0048] Step 3: Clean the inductively coupled plasma (ICP) reaction chamber to ensure that the chamber is clean and free from contamination. use 2 and SF 6 Mixed gas treatment for 3 minutes, and then O 2 Treatment for 3 minutes is mainly to remove residual organic polymer contamination in the ICP reaction chamber. The cleaning procedure uses 100W of RF power and 1500W of inductively coupled power.

[0049] Step 4: Send the epitaxial wafer with the imprinted grating pattern into the ICP reaction chamber f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com