Telephone receiver film and preparation method thereof

A film and earpiece technology, applied in the field of earpiece film and its preparation, can solve the problems affecting the sound quality of the speaker, poor rigidity of the plastic film, unstable sound quality, etc., and achieve the effects of convenient positioning and fixing, good conductivity, and small elastic hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing an earpiece film, comprising the following steps,

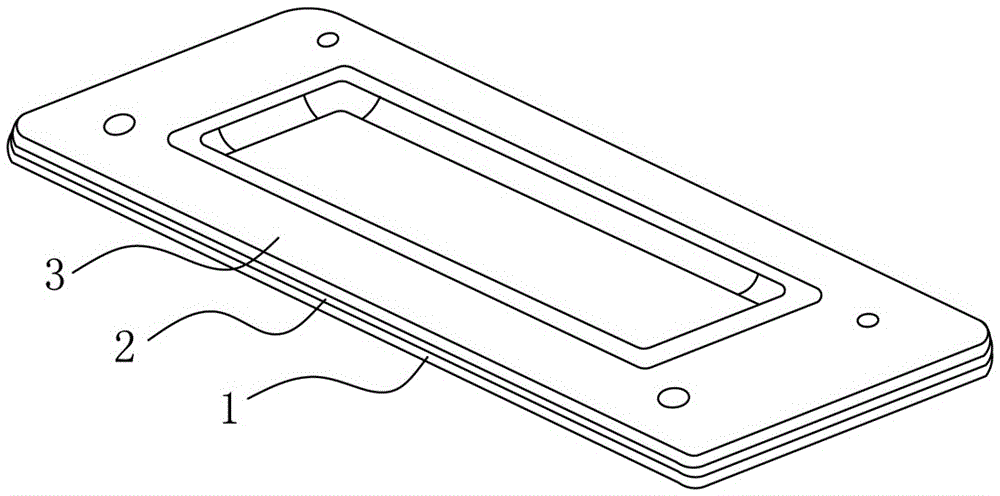

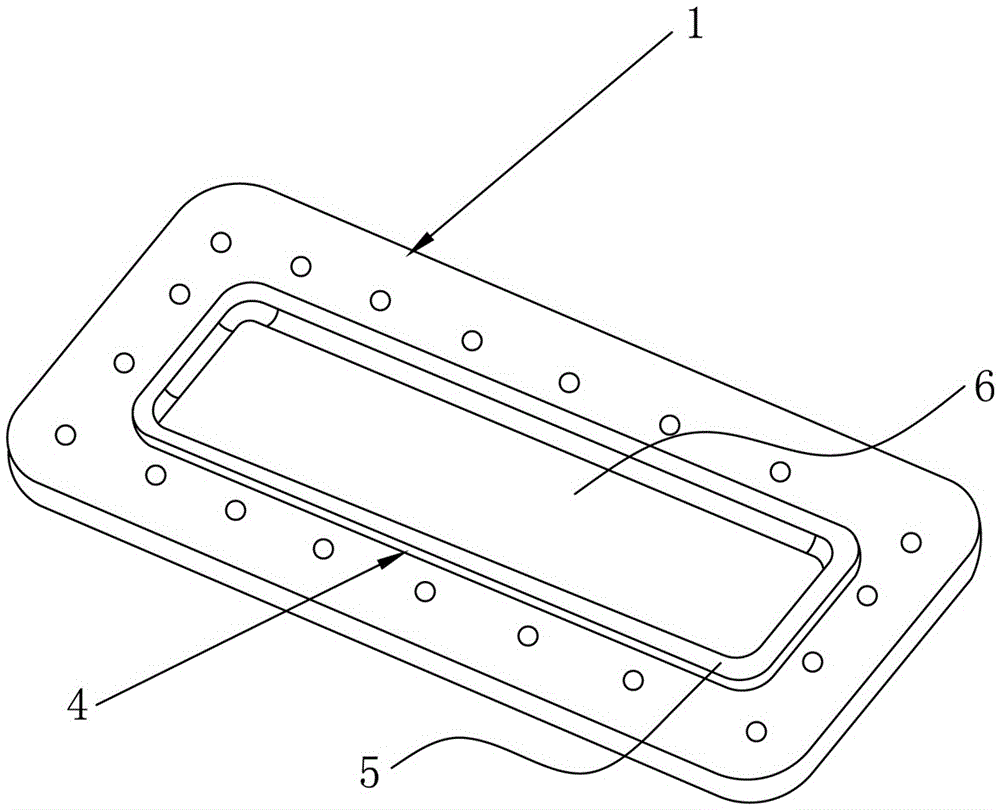

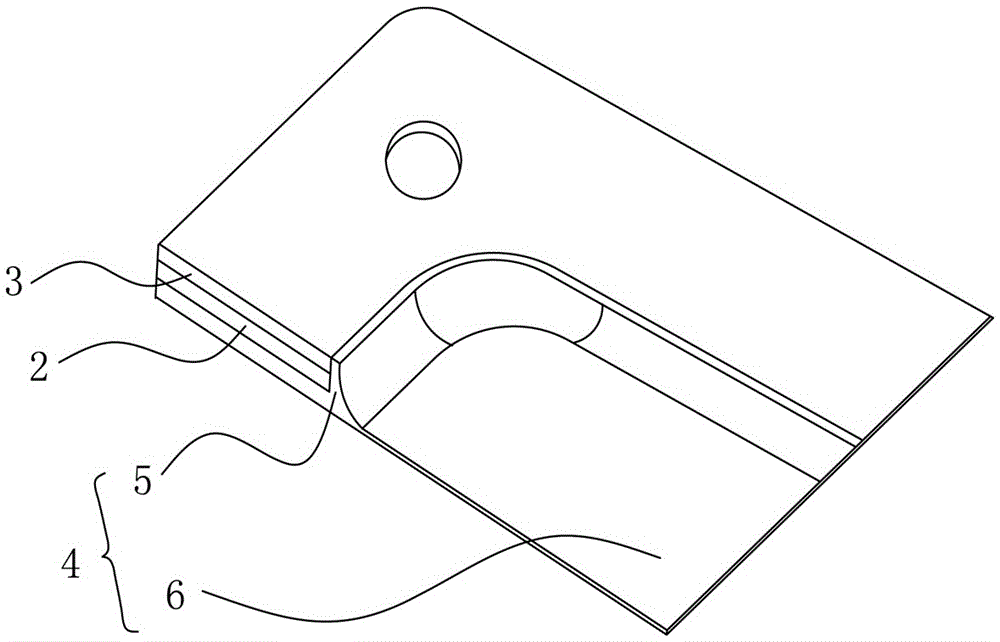

[0042] Step (A): Overlap, cut, punch and cut the middle original film and the surface original film to make a cover film. The cover film includes 2 sets of middle frames formed by the middle original film and 3 sets of surface frames punched out of the surface original film ;

[0043] Step (B): Use the fan gate to fill out the original engineering film, and then punch and cut it into small pieces to make the engineering film group;

[0044] Step (C): Clean the middle frame group 2, the surface frame group 3 and the engineering film group, coat the upper and lower surfaces of the middle frame group 2 with powder and glue, and then attach the surface frame group 3 to the upper surface of the middle frame group 2 , and finally stick the engineering film group on the lower surface of the middle frame 2 group, stamping and cutting out several earpiece films;

[0045] Wherein, the engineering film gr...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 lies in that the fan gate filling temperature in step (B) of this embodiment is 120° C., the locking pressure is 40 bar, and the locking speed is 12 s. The cleaning described in the step (C) is specifically coating and cleaning twice with a silica gel cleaning agent, and the coating thickness is 0.5 mm. The powder coating in the step (C) is specifically to use beryllium copper metal powder to spray on the surface ring 3 , the spraying temperature is 80° C., and the spraying thickness is 0.02 mm. The gluing in the step (C) uses a silane adhesive, the gluing pressure is 60 bar, and the hardness of the silane adhesive is 70 degrees.

[0057] The intermediate original film is composed of PEN:PEEK with a mass fraction of 1:2.

[0058] The Young's modulus of the earpiece film is 5400N / mm 2 , with a density of 1.3g / cm 3 , the glass transition temperature is 150°C, the relative damping is 0.48, the elongation is 400%, t...

Embodiment 3

[0060] The difference between this embodiment and Embodiment 1 lies in that the fan gate filling temperature in step (B) is 110° C., the locking pressure is 20 bar, and the locking speed is 10 s. The cleaning described in the step (C) is specifically to use a silica gel cleaning agent to coat and wash twice, and the thickness of the coating is 0.2 mm. The powder coating in the step (C) is specifically spraying on the surface ring 3 with beryllium copper metal powder, the spraying temperature is 110° C., and the spraying thickness is 0.03 mm. The gluing in the step (C) uses a silane adhesive, the gluing pressure is 60 bar, and the hardness of the silane adhesive is 70 degrees.

[0061] The intermediate original film is composed of PU:PET with a mass fraction of 1:2.

[0062] The Young's modulus of the earpiece film is 5200N / mm 2 , with a density of 1.2g / cm 3 , the glass transition temperature is 130°C, the relative damping is 0.45, the elongation is 300%, the tensile strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com