Gliding arc discharge plasma jet generation device and method thereof

A discharge plasma and plasma technology, applied in the direction of plasma, electrical components, etc., can solve the problems that the structure of the sliding arc discharge device is not flexible enough, compact, portable and stable, and it is not conducive to enlargement in practical applications and field applications, etc., to achieve The device is flexible, no pollution is obtained, and the effect of improving the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

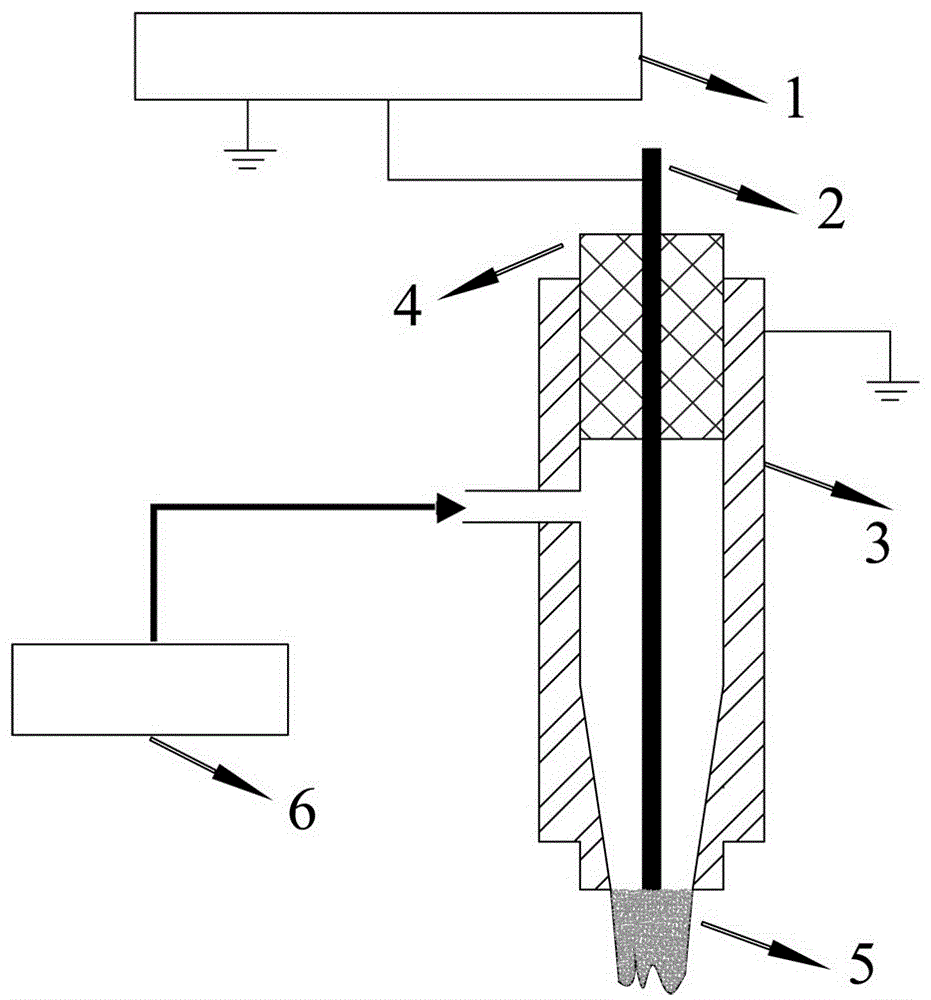

[0011] Such as figure 1 shown. The sliding arc discharge plasma jet device related to the present invention comprises a plasma generator, an external power source 1 and an external gas source 6; the plasma generator comprises a tubular outer electrode 3 with a tapered outlet, a central electrode 2 and a hollow insulating A support column 4, the insulating support column 4 plays the role of supporting and fixing the electrodes 2 and 3, the central electrode 2 is inserted into the center of the insulating support column 4 as a high-voltage electrode, and the tubular outer electrode 3 is used as a ground electrode and A gas channel is provided, and the two electrodes 2 and 3 are respectively connected to the two poles of the external power supply 1; the external power supply 1 is an AC power supply or a pulse power supply of 5 kHz to 30 kHz; the external gas source 6 is air or oxygen. It is characterized in that: the tubular outer electrode 3 is a molding process design integrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com