Preparing method of algicide base material, algicide and preparing method and application of algicide

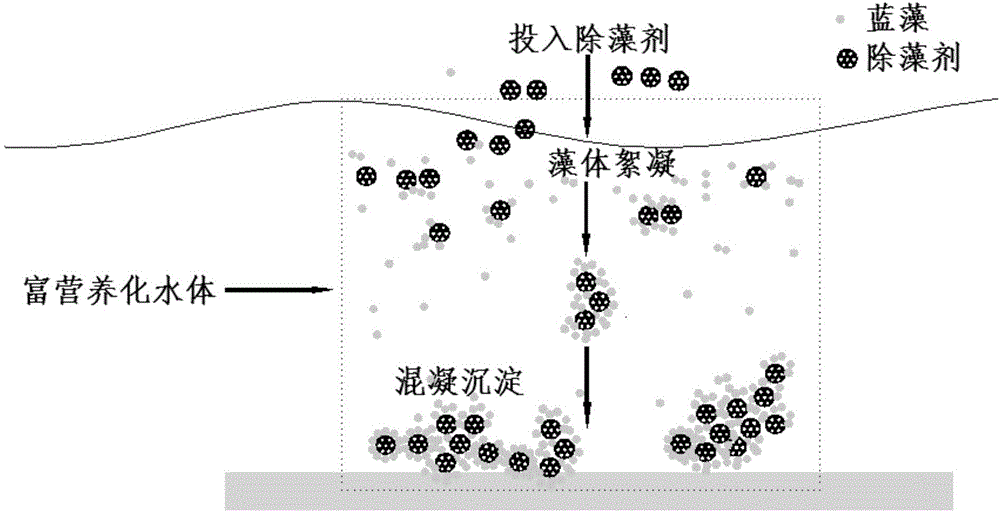

A technology of algicide and base material, applied in the direction of herbicide and algicide, botanical equipment and method, application, etc., can solve the problems of low cost performance, high processing cost, difficult operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

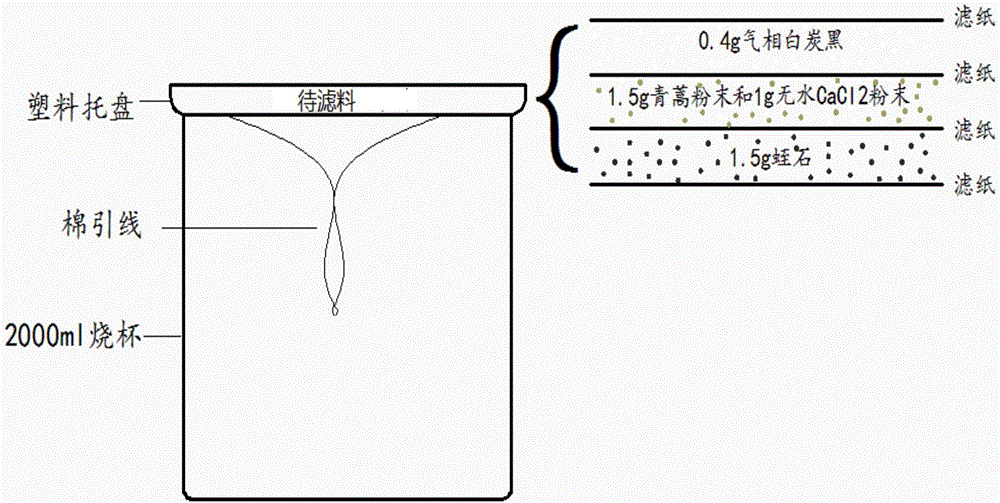

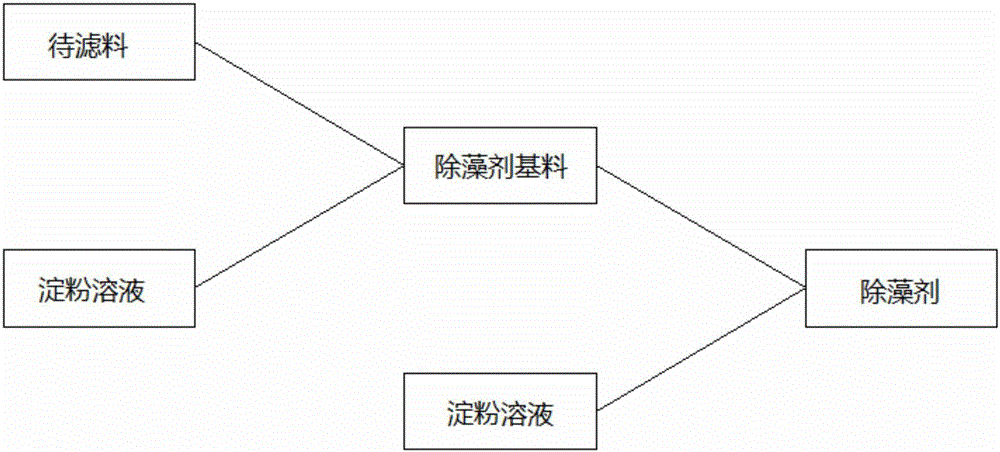

[0032] The invention provides a kind of preparation method of algicide base material, wherein, such as figure 2 Shown, described preparation method comprises:

[0033] 1) mixing Artemisia annua and calcium chloride to obtain a mixture M1, and separating the vermiculite, the mixture M1 and fumed silica with filter paper respectively to obtain a material to be filtered;

[0034] 2) mixing starch, hydrochloric acid and water to prepare a starch solution;

[0035] 3) The starch solution prepared in step 2) is mixed with the material to be filtered, and then filtered to obtain the algaecide base material.

[0036] In the above design, the material to be filtered is prepared by layering and superimposing vermiculite, Artemisia annua, calcium chloride, and fumed white carbon black, and the starch solution is mixed with the above-mentioned filter material to be filtered to obtain an algaecide base material. Then the algaecide base material is crystallized after being extracted with...

preparation example 1

[0059] 1) Pass vermiculite and Artemisia annua powder through a 100-mesh sieve. Put a 14cm-diameter plastic tray with holes (4-6 small holes with a diameter of 2mm can be manually drilled, and use cotton thread as drainage) plastic tray on a 2000mL beaker, put a 15cm qualitative filter paper on the tray to make the filter paper Embedded in a plastic tray, add 1.5g of vermiculite to the first layer of filter paper and use a brush to distribute it evenly on the filter paper; in the same way, add 15cm of filter paper to the first layer of filter paper, and then add 1.5g Artemisia annua powder and 1 g anhydrous CaCl 2 Powder and make it evenly distributed on the filter paper; cover the third layer of 15cm filter paper, add 0.4g fumed silica, and make it evenly distributed; finally, cover the fourth layer of filter paper;

[0060] 2) Weigh 0.1g of starch, add 10mL of 1% dilute HCl to dissolve, and make the volume to 250mL to obtain a starch solution;

[0061] 3) Add 25mL of starc...

preparation example 2

[0064] Prepare according to the preparation method of Preparation Example 1, the difference is that the consumption of the vermiculite is 1.6g, the consumption of the Artemisia annua powder is 1.6g, and the consumption of the fumed white carbon black is 0.3g, and the obtained Algae Base X2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com