Compound mature vinegar micro-capsules as well as preparation method and application thereof

A compound recipe and microcapsule technology, applied in the field of compound mature vinegar microcapsules and their preparation, can solve the problem that the oxidative stress level of liver cells has no exact influence, and achieve the effects of enhancing free radical scavenging ability, strong stability and long-lasting action time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

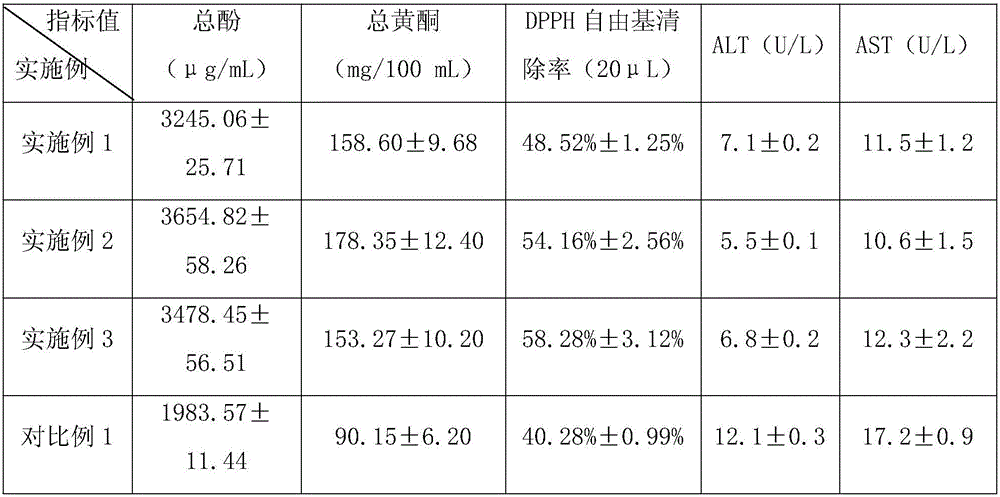

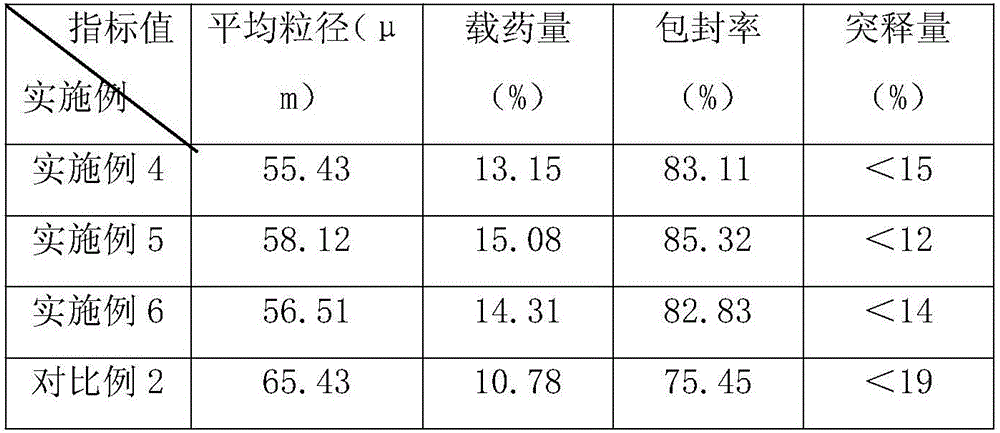

Examples

Embodiment 1

[0023] A method for preparing compound vinegar microcapsules, the method includes the following steps:

[0024] 1. Preparation of concentrated aged vinegar: take Shanxi aged vinegar, concentrate and extract at 35°C, and wait until the concentration of concentrated aged vinegar is 45°Bé;

[0025] 2. Preparation of traditional Chinese medicine extract: pulverize Schisandra, Astragalus, and Licorice respectively to a particle size of 5mm, and then add 75% ethanol to each pulverized powder for extraction three times, 40 minutes each time, ultrasonic extraction with ultrasonic power of 100W, ultrasonic The ultrasonic frequency of the extraction is 30kHz, and then it is filtered to recover the ethanol and concentrated to a thick paste with a relative density of 1.20-1.30 for use.

[0026] 3. Preparation of microcapsule core mixture: take 50 parts of concentrated old vinegar, 20 parts of schisandra extract, 15 parts of astragalus extract, 15 parts of licorice extract to prepare a medicine m...

Embodiment 2

[0030] A method for preparing compound vinegar microcapsules, the method includes the following steps:

[0031] 1. Preparation of concentrated aged vinegar: Take Shanxi aged vinegar and extract by vacuum concentration at 40°C. It can be used when the concentration of concentrated aged vinegar is 40°Bé;

[0032] 2. Preparation of traditional Chinese medicine extracts: pulverize Schisandra, Astragalus, and Licorice respectively to a particle size of 10mm, and then add 75% ethanol to each pulverized medicinal powder for extraction three times, each 50min, ultrasonic extraction ultrasonic power is 120W, ultrasonic The ultrasonic frequency of extraction is 40kHz, and then it is filtered to recover ethanol and concentrated to a thick paste with a relative density of 1.20-1.30 for use;

[0033] 3. Preparation of microcapsule core mixture: take 55 parts of concentrated old vinegar, 25 parts of schisandra extract, 10 parts of astragalus extract, 10 parts of licorice extract to prepare a medic...

Embodiment 3

[0037] A method for preparing compound vinegar microcapsules, the method includes the following steps:

[0038] 1. Preparation of concentrated aged vinegar: take Shanxi aged vinegar, concentrate and extract at 45°C, and wait until the concentration of concentrated aged vinegar is 50°Bé;

[0039] 2. Preparation of traditional Chinese medicine extract: schisandra, astragalus, licorice were crushed to a particle size of 8mm, and then 75% ethanol was added to each crushed medicinal powder to extract three times, each 60min, ultrasonic extraction ultrasonic power was 150W, ultrasonic The ultrasonic frequency of the extraction is 50kHz, and then it is filtered to recover the ethanol and concentrated to a thick paste with a relative density of 1.20-1.30 for use;

[0040] 3. Preparation of microcapsule core mixture: take 60 parts of concentrated aged vinegar, 23 parts of schisandra extract, 12 parts of astragalus extract, 12 parts of licorice extract to prepare a medicine mixture; then add 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com