Preparation method and application of water-soluble carbon quantum dots based on eggshell membranes

A technology of carbon quantum dots and eggshell membranes, applied in the field of preparation of fluorescent carbon quantum dots, can solve the problems of high energy consumption, complex preparation process, long time consumption, etc., and achieve the effects of low energy consumption, abundant sources and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method steps of the eggshell membrane-based water-soluble carbon quantum dots of the present embodiment are as follows:

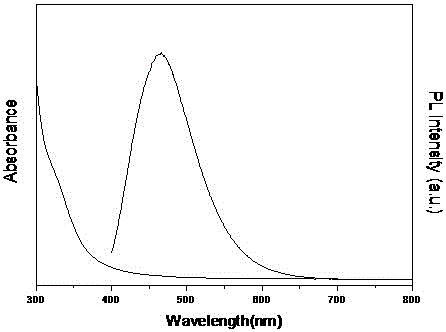

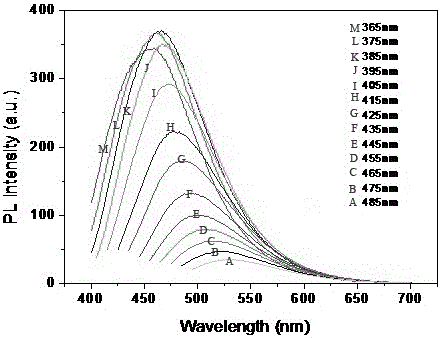

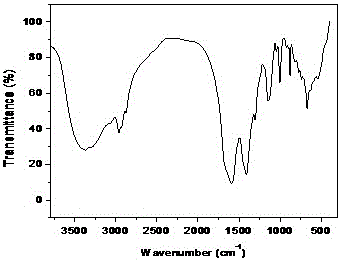

[0026] Peel the eggshell membrane from the inner wall of the eggshell, wash it three times with distilled water, dry it in an oven at 70°C, and cut it into pieces to obtain eggshell membrane fragments with a particle size of 30 mesh. Take 1.0 g of the fragmented eggshell membrane and place it in 20 mL Sodium hydroxide solution (0.2 mol / L), transfer the dispersion to a hydrothermal synthesis kettle whose inner wall is made of polytetrafluoroethylene, seal the reaction kettle and place it in an oven at 180°C for 9 hours, and wait for the reaction kettle to cool naturally The reaction solution was centrifuged (10000rpm) for 10min to remove impurities, the supernatant was placed in a dialysis bag with a molecular weight cut-off of 1000Da and dialyzed for 12 hours, and the product solution was freeze-dried at -80 degrees and then vacuum-dri...

Embodiment 2

[0029] The preparation method steps of the water-soluble carbon quantum dots based on the eggshell membrane of the present embodiment are as follows:

[0030] Peel the eggshell membrane from the inner wall of the eggshell, wash it three times with distilled water, dry it in an oven at 70°C, and cut it into pieces to obtain eggshell membrane fragments with a particle size of 50 mesh. Take 1.0 g of the fragmented eggshell membrane and place it in 50 mL Sodium hydroxide solution (0.1 mol / L), transfer the dispersion to a hydrothermal synthesis kettle whose inner wall is made of polytetrafluoroethylene, seal the reaction kettle and place it in an oven at 200°C for 6 hours, and wait for the reaction kettle to cool naturally The reaction solution was centrifuged (10000rpm) for 15min to remove impurities, the supernatant was placed in a dialysis bag with a molecular weight cut-off of 2000Da and dialyzed for 12 hours, the product solution was freeze-dried and vacuum-dried to obtain a po...

Embodiment 3

[0033] The preparation method steps of the water-soluble carbon quantum dots based on the eggshell membrane of the present embodiment are as follows:

[0034] Peel the eggshell membrane from the inner wall of the eggshell, wash it with distilled water for 3 times, dry it in a 70°C oven, and cut it into pieces to obtain eggshell membrane fragments with a particle size of 80 mesh. Take 1.0 g of the fragmented eggshell membrane and place it in 10 mL Sodium hydroxide solution (0.5 mol / L), transfer the dispersion to a hydrothermal synthesis kettle whose inner wall is made of polytetrafluoroethylene, seal the reaction kettle and place it in an oven at 170°C for 9 hours, and wait for the reaction kettle to cool naturally Centrifuge the reaction solution (10000rpm) for 20min to remove impurities, place the supernatant in a dialysis bag with a molecular weight cut-off of 500Da and dialyze for 12 hours, freeze-dry the product solution and then vacuum-dry to obtain a powdered carbon quant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com