Cationic flocculant and its preparation method

A cationic flocculant and its production method technology are applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, special treatment targets, etc. It can solve the problems of high residue amount and long flocculation time, achieve high flocculation degree and speed up Effect of flocculation speed and reduction of residue amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

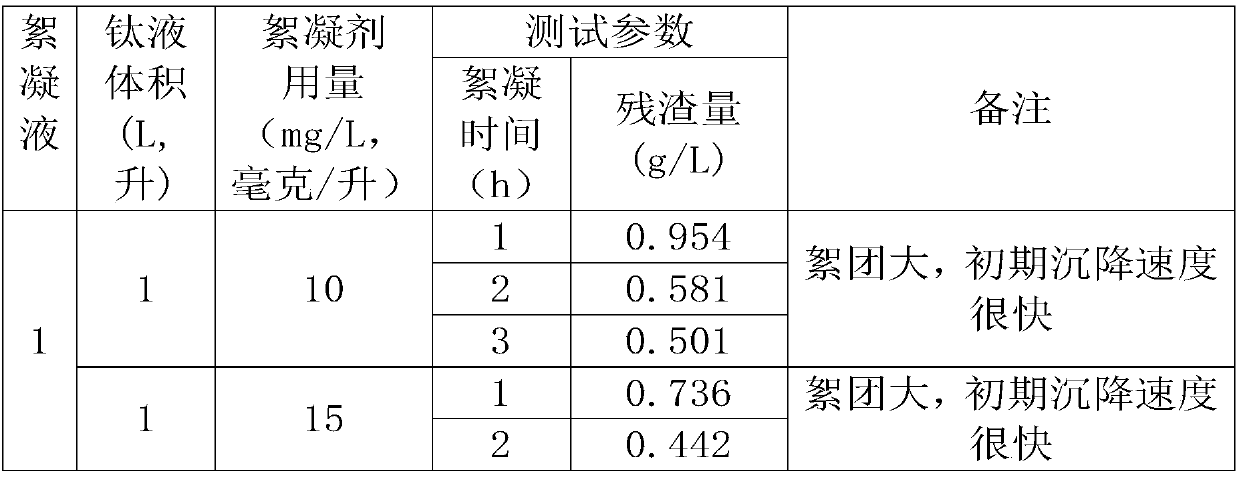

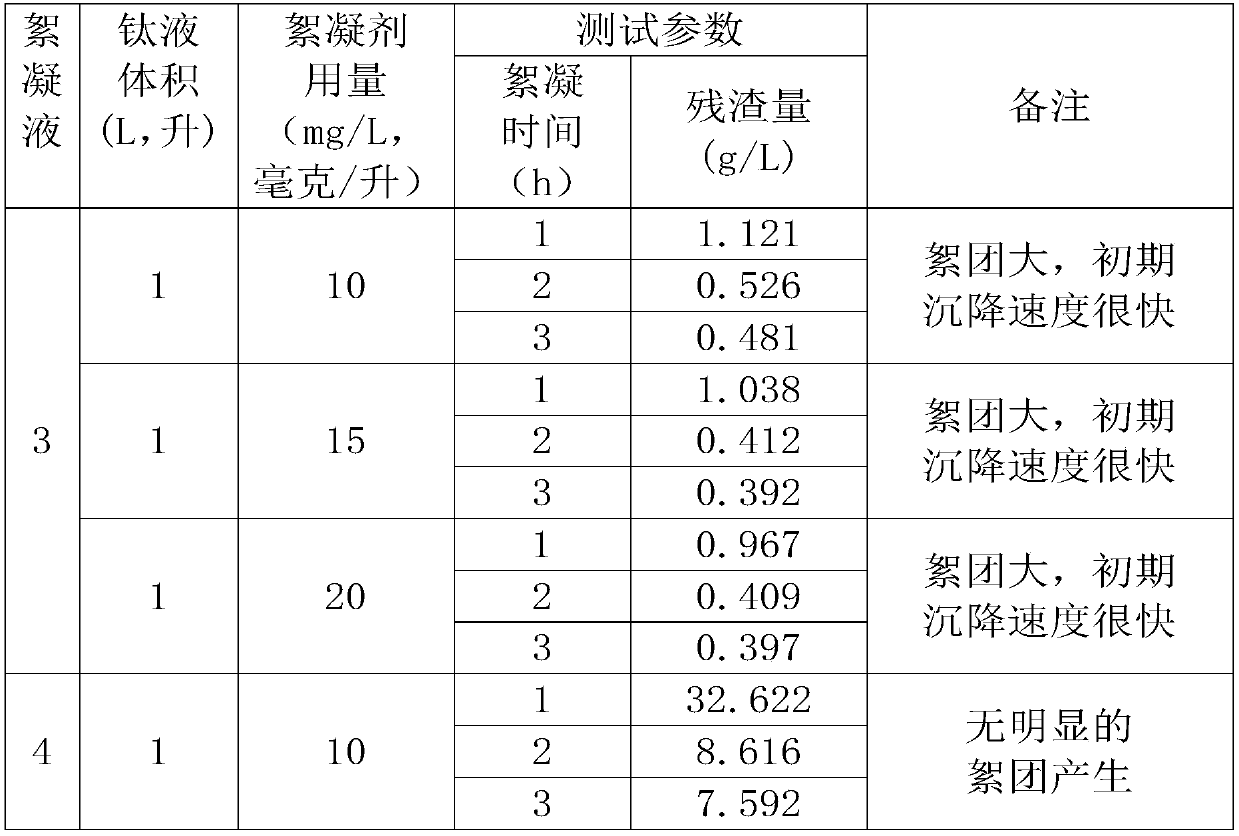

Embodiment 1

[0050] This example provides a cationic flocculant, which is made of the following components:

[0051] Acrylamide 25g;

[0052] Methacryloyloxyethyltrimethylammonium chloride 30g;

[0053] Acryloyloxyethyltrimethylammonium chloride 20g;

[0054] Dimethyl diallyl ammonium chloride 10g;

[0055] Dimethylaminoethyl methacrylate 10g,

[0056] The weight of each of the above components is based on dry matter weight.

[0057] The preparation method of this flocculant is as follows:

[0058] In the first step, the raw materials of each component are dissolved in water to form an aqueous solution, and then the pH value of the aqueous solution is adjusted to 2 with citric acid to obtain a regulating solution.

[0059] In the second step, nitrogen is injected into the container holding the regulating liquid to discharge the oxygen in the regulating liquid so that the oxygen content of the regulating liquid is 0.001 mg / L to obtain a reaction liquid.

[0060] In the third step, amm...

Embodiment 2

[0077] This example provides a cationic flocculant, which is made of the following components:

[0078] Acrylamide 15g;

[0079] Methacryloyloxyethyltrimethylammonium chloride 35g;

[0080] Acryloyloxyethyltrimethylammonium chloride 20g;

[0081] Dimethyl diallyl ammonium chloride 15g;

[0082] Dimethylaminoethyl methacrylate 10g,

[0083] The weight of each of the above components is based on dry matter weight.

[0084] The preparation method of this flocculant is as follows:

[0085] In the first step, the raw materials of each component are dissolved in gram water to form an aqueous solution, and then the pH value of the aqueous solution is adjusted to 5 with adipic acid to obtain a regulating solution.

[0086] In the second step, nitrogen is injected into the container holding the regulating liquid to discharge the oxygen in the regulating liquid so that the oxygen content of the regulating liquid is 0.0004 mg / L to obtain a reaction liquid.

[0087] In the third ste...

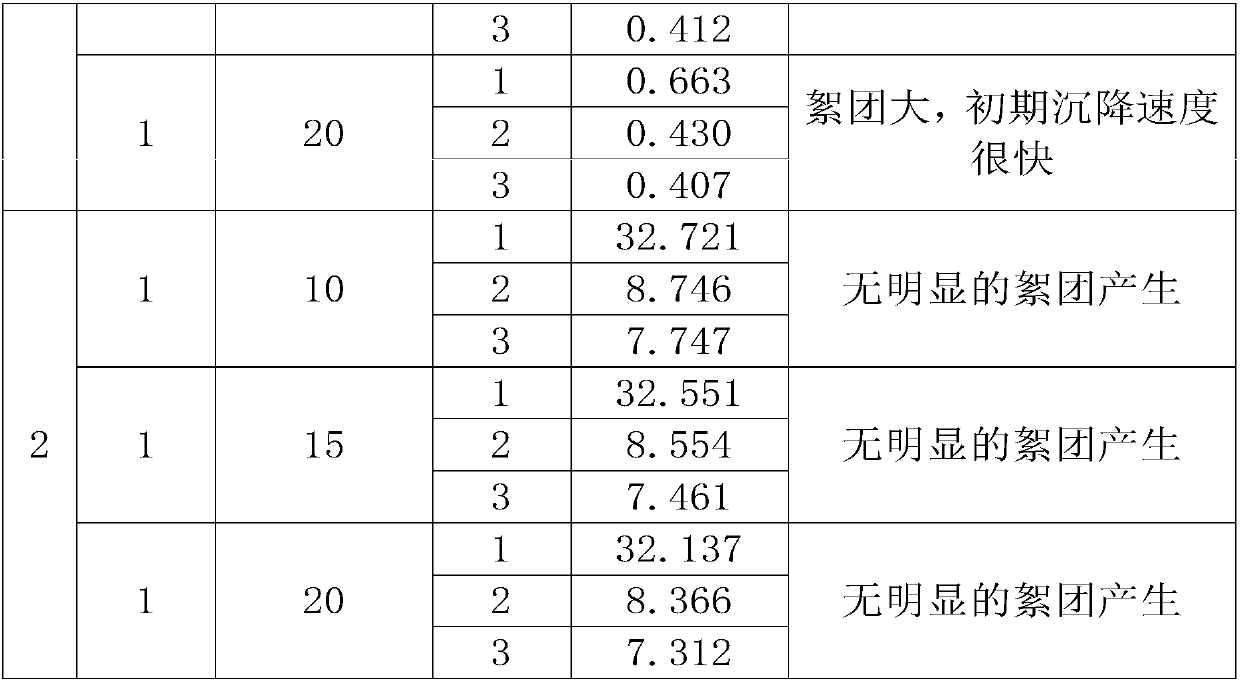

Embodiment 3

[0104] This example provides a cationic flocculant, which is made of the following components:

[0105] Methacryloyloxyethyltrimethylammonium chloride 40g;

[0106] Acryloyloxyethyltrimethylammonium chloride 20g;

[0107] Dimethyl diallyl ammonium chloride 25g;

[0108] Dimethylaminoethyl methacrylate 15g,

[0109] The weight of each of the above components is based on dry matter weight.

[0110] The preparation method of this flocculant is as follows:

[0111] In the first step, the above-mentioned components are dissolved in water to form an aqueous solution, and then the pH value of the aqueous solution is adjusted to 4 with hydrochloric acid to obtain a regulating solution.

[0112] In the second step, nitrogen is injected into the container holding the regulating liquid to discharge the oxygen in the regulating liquid so that the oxygen content of the regulating liquid is 0.0001 mg / L to obtain a reaction liquid.

[0113] In the third step, potassium persulfate, sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com