Preparation method and product of polycarboxylate superplasticizer comprising amido groups

A high-efficiency water reducer and polycarboxylate-based technology, applied in the field of concrete admixtures, can solve the problems of low polymerization reactivity, affecting the key performance of polycarboxylate-based water-reducers, polymer properties, etc., to achieve high initial Dispersion and dispersibility over time, excellent retarding effect, and effect of improving electrostatic repulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

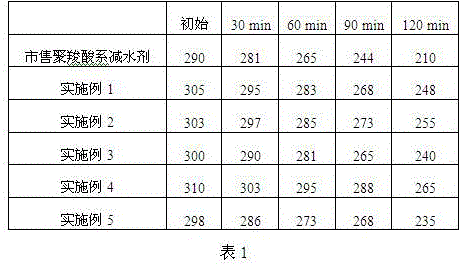

Examples

preparation example Construction

[0024] In the first aspect, the present invention provides a method for preparing an amide-containing polycarboxylate superplasticizer, comprising the following steps:

[0025] (1) Add maleic anhydride and / or maleic anhydride esterification product and acrylamide into the reaction vessel, add water to fully dissolve, heat up to 70°C~85°C, stir mechanically, and drop potassium persulfate aqueous solution as an initiator at the same time , after dropping, continue mechanical stirring to carry out the polymerization reaction until the reaction is complete; cool down to room temperature, and post-process to obtain modified acrylamide;

[0026] (2) Add the modified acrylamide, unsaturated polyether, and unsaturated carboxylic acid into another reaction container, add deionized water, and stir to dissolve; then add vitamin C, stir to dissolve; then control When the temperature of the reaction solution reaches 15°C~35°C, add hydrogen peroxide dropwise and stir to carry out the copoly...

Embodiment 1

[0039] (1) Add 100g of maleic anhydride and 100g of acrylamide into the reaction vessel, add water to fully dissolve, raise the temperature to 75°C, stir mechanically, and at the same time add potassium persulfate aqueous solution as an initiator dropwise, and continue mechanically stirring for 60min after the dripping is completed. Carry out the polymerization reaction until the reaction is complete; cool down to room temperature, and perform post-treatment to obtain modified acrylamide;

[0040] (2) Add 100g of the modified acrylamide, 500g of prenyl polyoxyethylene ether (TPEG) with an average molecular weight of 2400, and 50g of acrylic acid into another reaction vessel, and add a certain amount of deionized water , fully stir to dissolve; then add 10g of vitamin C, stir to dissolve; then control the temperature of the reaction solution to 25°C, add 15g of hydrogen peroxide dropwise, and stir for 180min to carry out the copolymerization reaction;

[0041] (3) Add sodium hy...

Embodiment 2

[0043] (1) Add 100g of maleic anhydride esterification product and 100g of acrylamide into the reaction vessel, add water to fully dissolve, heat up to 80°C, stir mechanically, and at the same time add potassium persulfate aqueous solution as an initiator dropwise, after dropping, continue mechanically Stir for 75 minutes, carry out the polymerization reaction until the reaction is complete; cool down to room temperature, and perform post-treatment to obtain modified acrylamide;

[0044] (2) Add 100g of the modified acrylamide, 750g of methallyl polyoxyethylene ether (HPEG) with an average molecular weight of 3600, and 50g of methacrylic acid into another reaction vessel, and add a certain amount of Deionized water, fully stir to dissolve; then add 15g of vitamin C, stir to dissolve; then control the temperature of the reaction solution to 20°C, add 25g of hydrogen peroxide dropwise, and stir for 210min to carry out the copolymerization reaction;

[0045] (3) Add sodium hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com