A kind of method of ethylene oligomerization

A technology of ethylene oligomerization and ethylene, which is applied in the direction of chemical instruments and methods, hydrocarbons, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of polymerization process reaction initiation and poor repeatability, and the price of modified MMAO Expensive, unfavorable ethylene oligomerization process and other problems, to achieve the effect of rapid reaction initiation, low price and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The ethylene oligomerization reaction specifically comprises the steps:

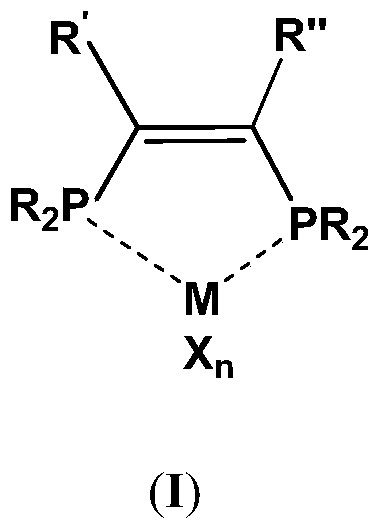

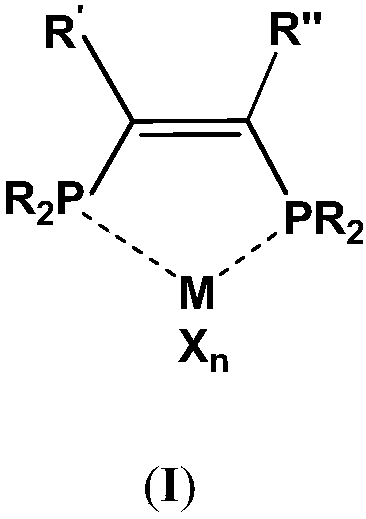

[0034] (1) In a continuous reaction device, water-containing ethylene, solvent n-heptane, metal procatalyst solution (concentration is 2.5 μ mol / mL, such as formula I, wherein 4 Rs are all phenyl groups, M is chromium, and X is chlorine , n=3), cocatalyst trimethylaluminum solution (concentration is 1mmol / mL) enters reactor respectively, and its flow rate is 80g / h, 160g / h, 3.5g / h, 2.6g / h, keeps in the reaction system Al / Cr mol ratio is 500, and the residence time that keeps reaction material in reactor is 30 minutes;

[0035] (2) The reaction pressure is 5MPa and the reaction temperature is 80°C, wherein, based on ethylene, the mass content of water is 400 mg / Kg (ppm);

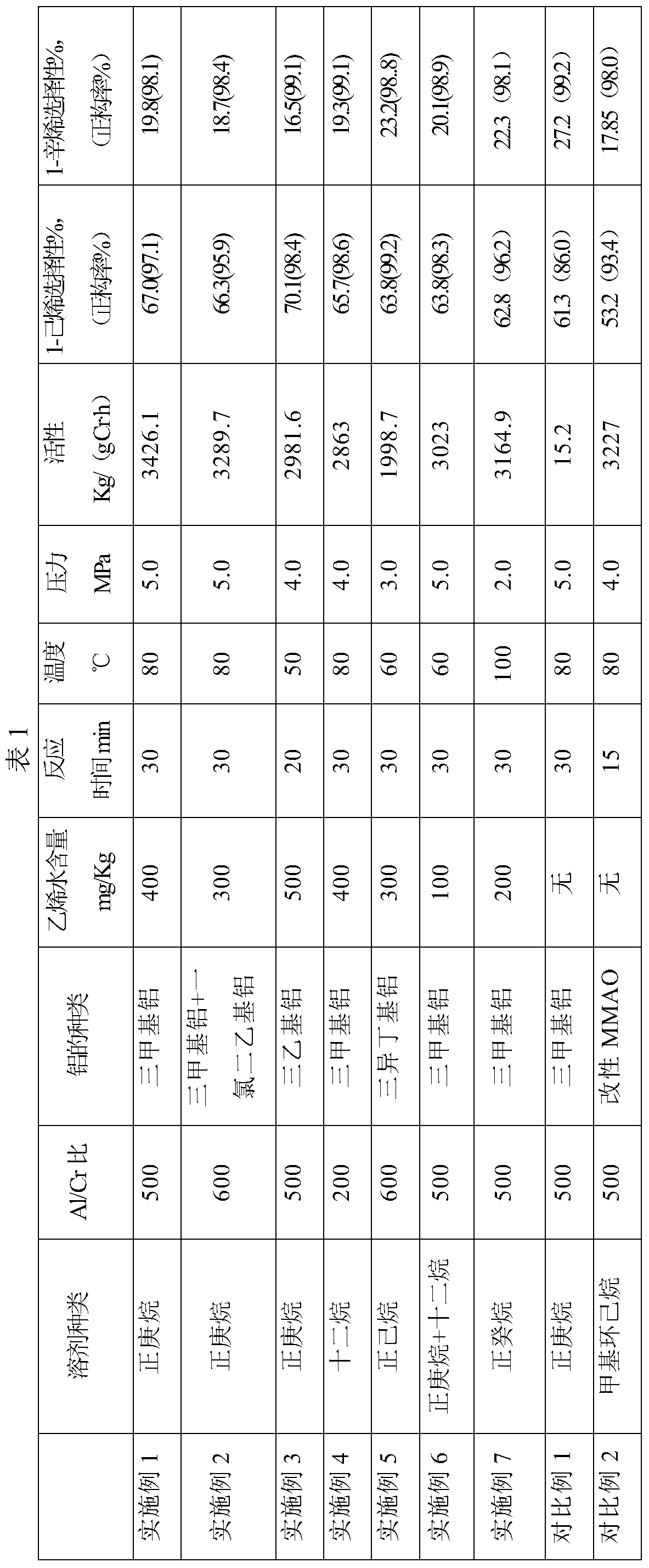

[0036] (3) Carry out gas chromatography (GC) analysis to the reaction outlet material. See attached table 1 for the data.

Embodiment 2

[0038] The specific steps are the same as in Example 1, except that the cocatalyst is a mixed solution of 300 equivalents of trimethylaluminum and 300 equivalents of diethylaluminum chloride, the Al / Cr ratio is 600, and the ethylene water content is 300 mg / Kg. The results of ethylene oligomerization are shown in Table 1.

Embodiment 3

[0040] The specific steps are the same as in Example 1, the cocatalyst is triethylaluminum, the Al / Cr ratio is 500, the reaction temperature is 50° C., the pressure is 4.0 MPa, the ethylene water content is 500 mg / Kg, and the reaction time is 20 minutes. The results of ethylene oligomerization are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com