Efficient preparation method and application of poly beta-farnesene with ultra-high molecular weight

A technology of ultra-high molecular weight and farnesene, which is applied in chemical recycling and other fields, and can solve the problems of low molecular weight of poly-β-farnesene and high cost of rare earth metal reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

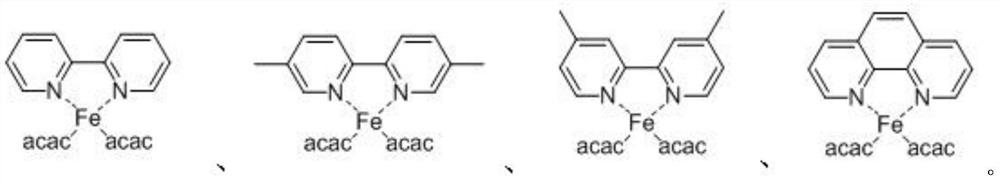

[0036] Specific embodiment one: the efficient preparation method of a kind of poly-beta-farnesene of the present embodiment is carried out according to the following steps:

[0037] Take a Schlenk bottle, add 30 mL of toluene, cocatalyst MAO (2.5 mmol, 500 equiv, 1.67 mL), β-farnesene monomer (25 mmol, 5000 equiv, 6.3 mL) and Pyridine iron complex 1 (5μmol, 1equiv, 2.1mg), after polymerization at 25°C for 30min under stirring, add 20mL of a mixed solution of hydrochloric acid and methanol and 5mL of anti-aging agent to quench the reaction, pour off the clear After the solution, the polymer was washed 3 times with ethanol, and the obtained polymer was vacuum-dried to constant weight at 40°C to obtain poly-β-farnesene; the volume ratio of methanol to concentrated hydrochloric acid in the mixed solution of hydrochloric acid and methanol was 50 :1.

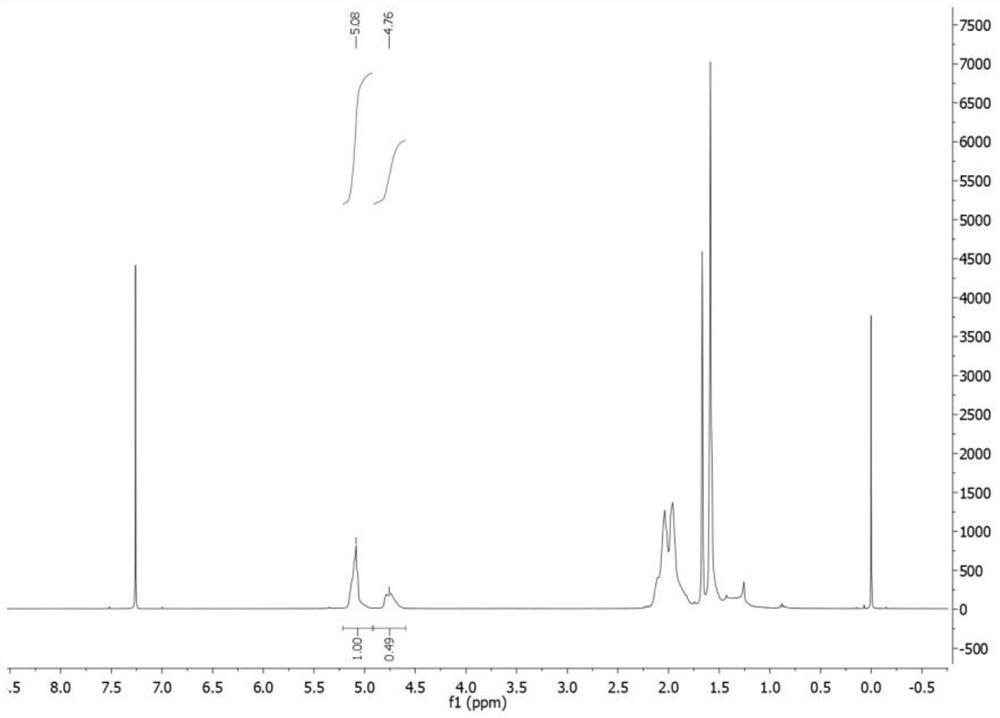

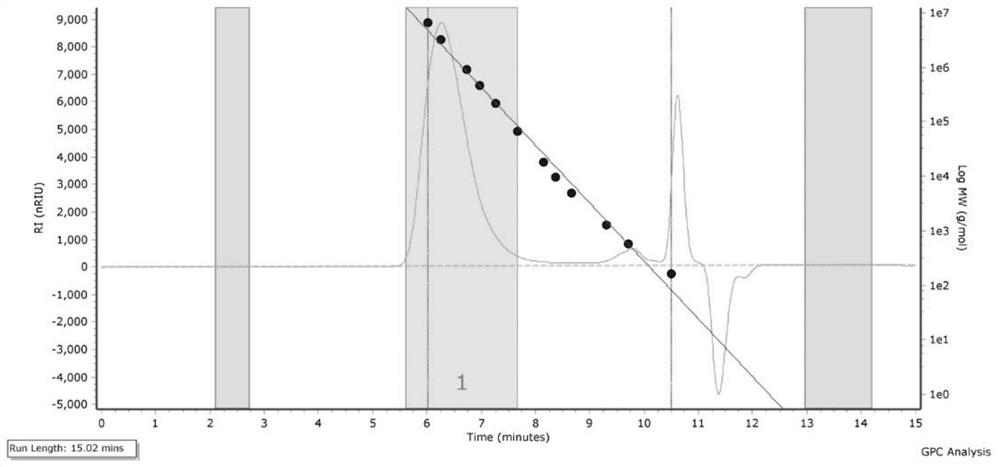

[0038] The yield of this embodiment is >99%. The microstructural selectivity of the polymer was: 45% 1,4-poly-β-farnesene and 55% ...

specific Embodiment approach 2

[0046] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the amount of co-catalyst MAO is (1.25 mmol, 250 equiv, 0.83 mL). Other steps and parameters are the same as those in the first embodiment.

[0047] The yield of this embodiment was 97%. The microstructural selectivity of the polymer was: 45% 1,4-poly-β-farnesene and 55% 3,4-poly-β-farnesene, M n (Number average molecular weight, g / mol) was 1.47 million, and PDI (molecular weight distribution) was 2.6.

specific Embodiment approach 3

[0048] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the cocatalyst is MMAO, and the dosage is (2.5 mmol, 500 equiv, 1.25 mL). Other steps and parameters are the same as those in the first embodiment.

[0049] The yield of this embodiment is >99%. The microstructural selectivity of the polymers was: 46% 1,4-poly-β-farnesene and 54% 3,4-poly-β-farnesene, M n (Number average molecular weight, g / mol) was 1.3 million, and PDI (molecular weight distribution) was 1.9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com