High-ortho benzyl ether phenolic resin and preparation method thereof, and method for applying high-ortho benzyl ether phenolic resin to cold box binder

A technology of phenolic resin and binder, which is applied in the field of high-ortho-benzyl ether phenolic resin with high methylol content and its preparation, can solve the problem of not completely improving the collapsibility of resin sand cores, and can not effectively improve the curing performance of resin and other problems, to achieve the effect of improving normal temperature performance and curing speed, high sand core strength, and improving normal temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

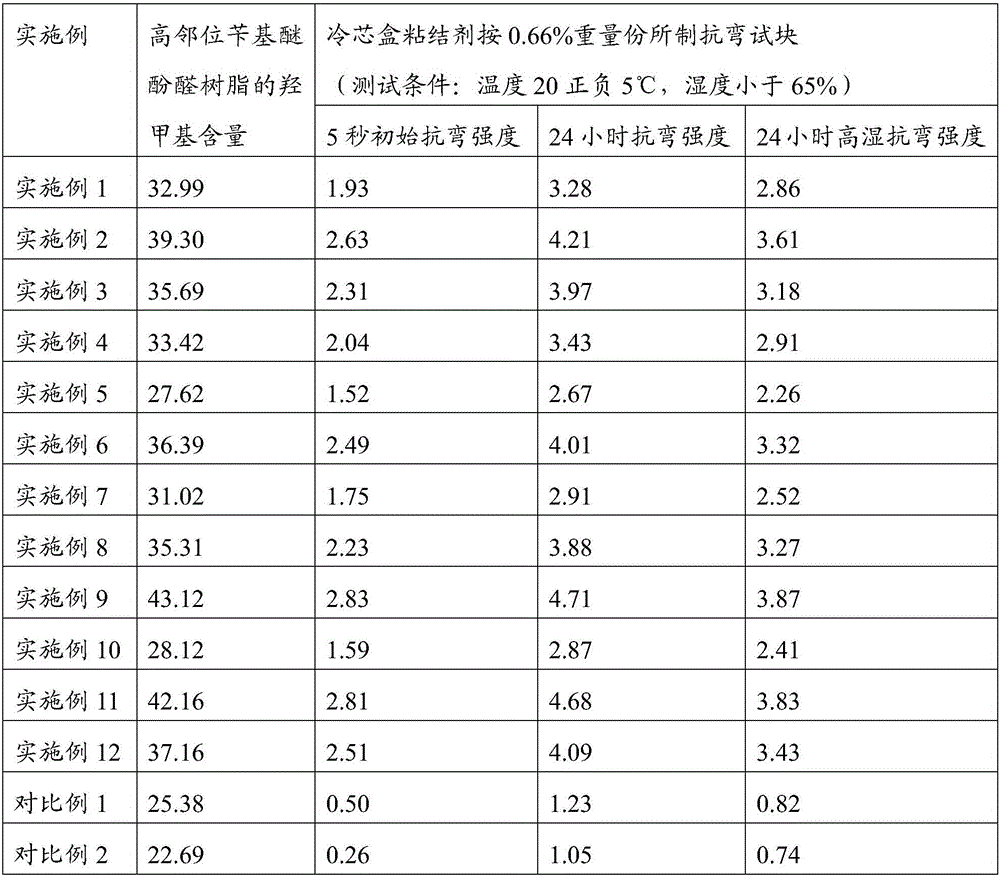

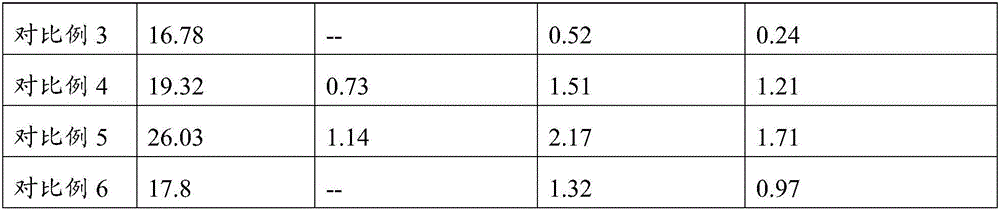

Examples

Embodiment 1

[0060] The preparation method of high ortho benzyl ether phenolic resin is as follows:

[0061] Step 1: Put 420 kg of melted phenol, 60 kg of bisphenol A, 312 kg of paraformaldehyde, 4 kg of calcium oxide, and 0.6 kg of zinc acetate into the reactor and stir evenly, and use a pH regulator to lower the mixture at 30-40°C PH value is 4~7;

[0062] Step 2: Adjust the reactor condenser to the reflux state, raise the temperature under stirring, raise the temperature to 95°C within 60 minutes, and keep the reaction at 95-105°C for 90 minutes;

[0063] Step 3: Adjust the reaction kettle to the normal pressure fractionation state, raise the temperature inside the kettle to 115°C within 60 minutes, and keep the reaction at 115-120°C for 60 minutes;

[0064] Step 4: After the heat preservation is completed, cool down to below 100°C, then vacuumize to make the vacuum degree reach 300mmHg, and vacuumize for 30 minutes to obtain a high-ortho benzyl ether phenolic resin with a high methylo...

Embodiment 2

[0066] The preparation method of high ortho benzyl ether phenolic resin is as follows:

[0067] Step 1: Put 420 kg of melted phenol, 60 kg of bisphenol A, 398 kg of paraformaldehyde, 4 kg of calcium oxide, and 1 kg of zinc acetate into the reaction kettle and stir evenly, and use a pH regulator to lower the mixture at 30-40°C PH value is 5~6;

[0068] Step 2: Adjust the reactor condenser to the reflux state, raise the temperature under stirring, raise the temperature to 95°C within 60 minutes, and keep the reaction at 95-105°C for 90 minutes;

[0069] Step 3: Adjust the reaction kettle to the normal pressure fractionation state, raise the temperature inside the kettle to 115°C within 60 minutes, and keep the reaction at 115-120°C for 60 minutes;

[0070] Step 4: After the heat preservation is completed, cool down to below 100°C, and then vacuumize to make the vacuum degree reach 600mmHg, and vacuumize for 25 minutes to obtain a high-ortho benzyl ether phenolic resin with a hi...

Embodiment 3

[0072] The preparation method of high ortho benzyl ether phenolic resin is as follows:

[0073] Step 1: Put 420 kg of melted phenol, 60 kg of bisphenol A, 368 kg of paraformaldehyde, 4 kg of calcium oxide, and 1 kg of zinc acetate into the reactor and stir evenly, and use a pH regulator to lower the mixture at 30-40°C 5 to 6;

[0074] Step 2: Adjust the reactor condenser to the reflux state, raise the temperature under stirring, raise the temperature to 95°C within 60 minutes, and keep the reaction at 95-105°C for 90 minutes;

[0075] Step 3: Adjust the reaction kettle to the normal pressure fractionation state, raise the temperature inside the kettle to 115°C within 60 minutes, and keep the reaction at 115-120°C for 60 minutes;

[0076] Step 4: After heat preservation is completed, cool down to below 100°C, then vacuumize to make the vacuum degree reach 400mmHg, and vacuumize for 30 minutes to obtain a high-ortho benzyl ether phenolic resin with high methylol content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com