Highly active phenolic compound modified expandable phenolic resin and preparation method thereof

A high-activity phenolic and phenolic resin technology, which is applied in the field of preparation of high-active phenolic compounds modified expandable high-solid phenolic resins, can solve problems such as high curing temperature, low activity of phenolic resins, and many acidic curing agents. Achieve the effects of lower curing temperature, increased methylol content, and improved resin activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Add 35g of phenol, 0.5g of calcium oxide, and 10g of water into a four-neck flask with a condenser, raise the temperature to 70°C for reaction, and add 4g of paraformaldehyde for 10 minutes;

[0023] (2) Add 11 g of paraformaldehyde to the mixed solution of (1) reaction, add in 3 times, control the reaction temperature at 70° C., and co-condense for 30 minutes;

[0024] (3) Cool down to 55° C., add 0.5 g of m-cresol and continue the reaction for 20 minutes, cool to 40° C. and discharge to prepare m-cresol-modified expandable phenolic resin.

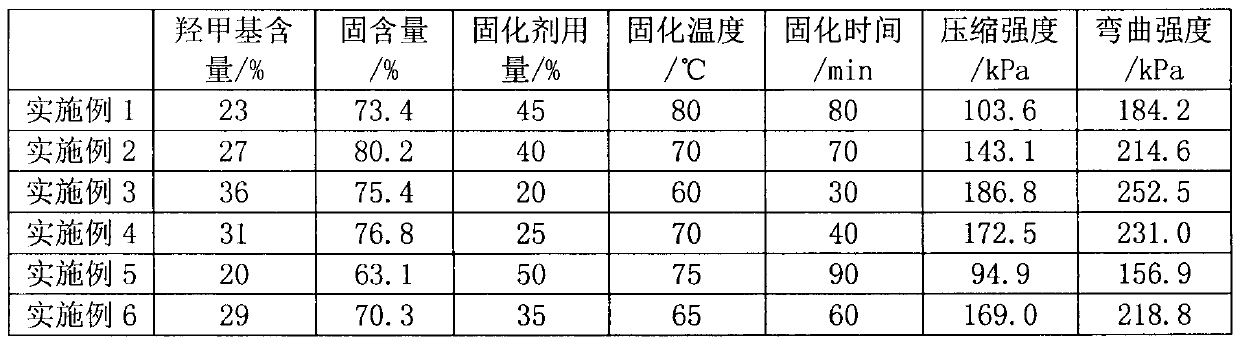

[0025] See attached table 1 for the basic properties of the resin and the curing process conditions.

Embodiment 2

[0027] (1) 55g phenol, 16.5g 30% (wt) Ba(OH) 2 Add the solution and 20g of water into a four-neck flask with a condenser, raise the temperature to 90°C, add 10g of furfural and react for 30 minutes;

[0028] (2) add furfural 30g in the mixed solution of (1) reaction, add in 3 times, control reaction temperature 90 ℃, co-condensation reaction 60 minutes;

[0029] (3) Cool down to 75° C., add 10 g of p-cresol and continue the reaction for 60 minutes, cool to 40° C. and discharge to prepare p-phenol-modified expandable phenolic resin.

[0030] See attached table 1 for the basic properties of the resin and the curing process conditions.

Embodiment 3

[0032] (1) 45g of phenol, 7.5g of 30% (wt) NaOH solution, and 10g of water were added to a four-neck flask with a condenser tube, the temperature was raised to 85°C, and 6g of paraformaldehyde was added to react for 20 minutes;

[0033] (2) Add 24 g of paraformaldehyde to the mixed solution of (1) reaction, add in 4 times, control the reaction temperature at 85° C., and co-condense for 40 minutes;

[0034] (3) Cool down to 65° C., add 5 g of resorcinol to continue the reaction for 35 minutes, cool to 40° C. and discharge to prepare a resorcinol-modified expandable phenolic resin.

[0035] See attached table 1 for the basic properties of the resin and the curing process conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com