Photocured rosin-based polyester resin for UV offset ink and preparation method of photocured rosin-based polyester resin

An offset printing ink and polyester resin technology, applied in the field of printing ink, can solve the problems of insufficient package wettability and poor substrate adhesion, and achieve the effects of high adhesion fastness, fast curing speed and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

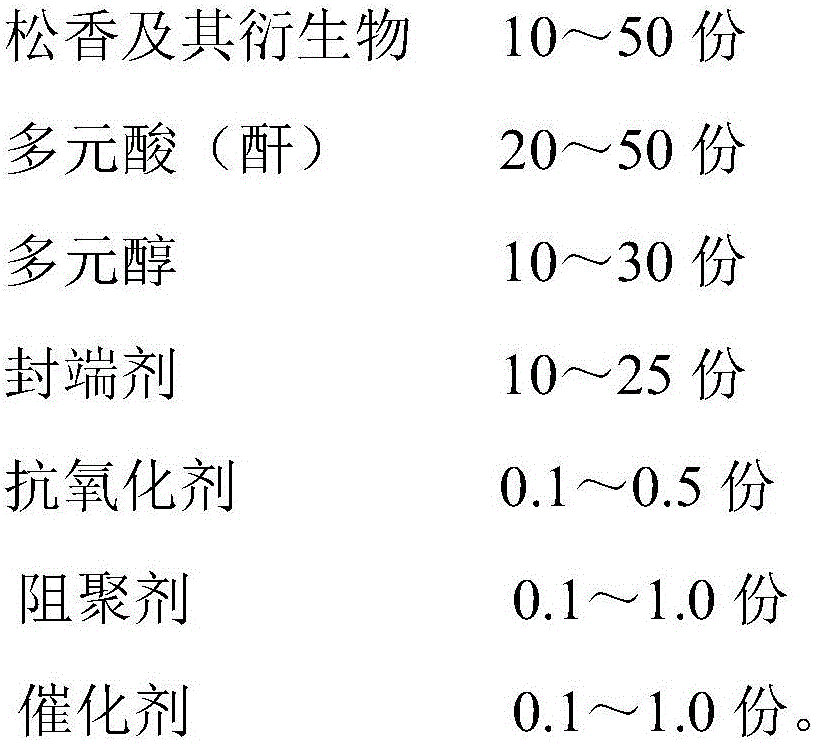

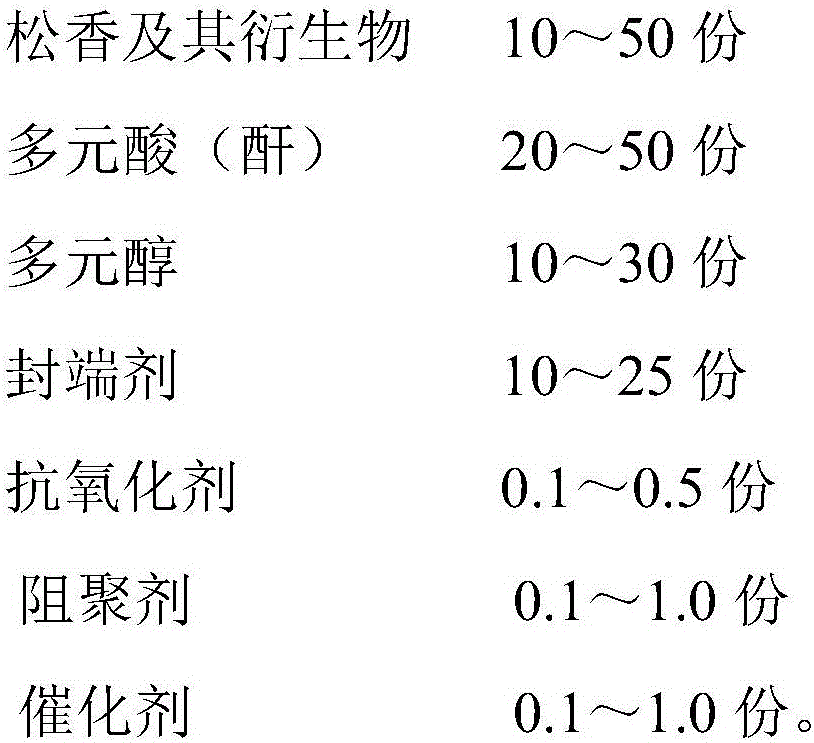

[0032] The present invention also discloses a method for preparing the above-mentioned photocurable rosin-based polyester resin for UV offset printing ink, comprising the following steps:

[0033] (1) Under the protection of an inert gas, mix 10-50 parts of rosin and its derivatives, 10-30 parts of polyols, 20-50 parts of polybasic acids (anhydrides), 0.1-0.5 parts of antioxidants, 0.1-1.0 parts of inhibition Agent and 0.1~1.0 part of catalyst are added to the distillation column, N 2 In the reaction device (apparatus) of protection, thermometer and mixer, first raise the temperature to 130-150°C to melt part of the materials and mix them evenly, then raise the temperature to 170-190°C for 5.0-8.0h, then raise the temperature to 190-230°C for 3.0 ~5.0h;

[0034] (2) Finally, the temperature is raised to 250-280°C and the reaction is continued for 3.0-5.0 hours;

[0035] (3) Cool down to 135-160°C, add 10-25 parts of end-capping agent, heat up to 180-210°C for 1.0-3.0 hours, ...

Embodiment 1

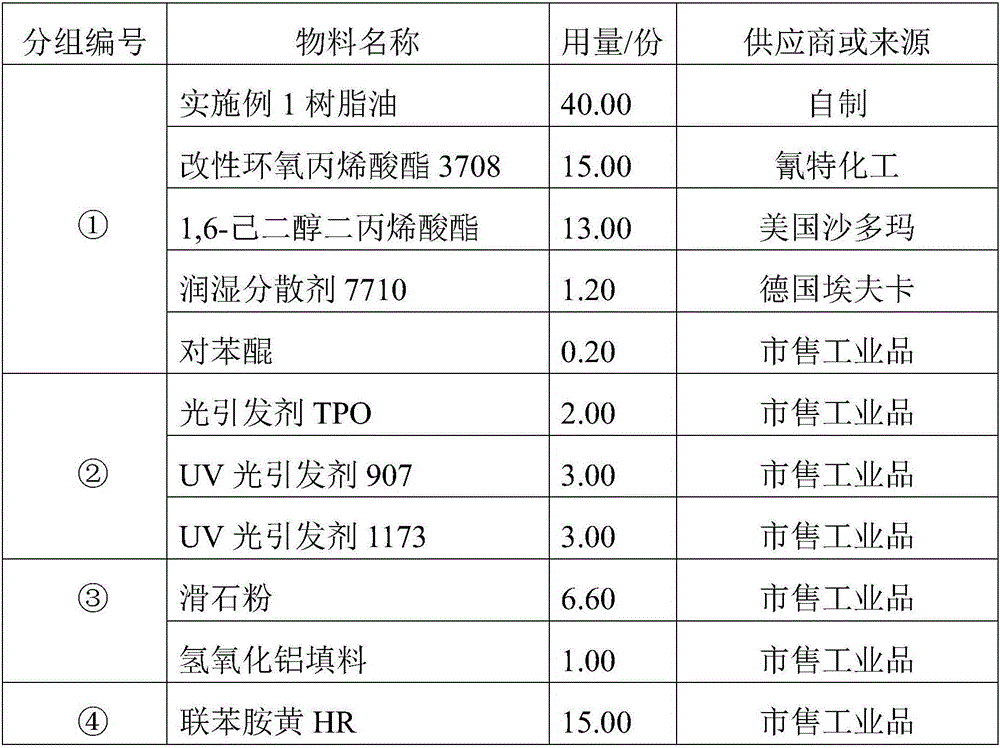

[0039] A kind of UV offset printing ink of the present embodiment comprises the UV offset printing ink that is made by photocuring rosin-based polyester resin for UV offset printing ink, is to adopt and comprise the following steps to make:

[0040] 1. Prepare materials

[0041] Prepare raw materials according to the following weight ratio: 25g phthalic anhydride, 5.0g terephthalic acid, 20.0g isophthalic acid, 10.0g maleic rosin, 15.0g ethylene glycol, 8.0g 1,2-propanediol, 7.0 g trimethylolpropane, 10.0 g oleic acid, 0.1 g methanesulfonic acid, 0.1 g hydroquinone, 0.1 g butyl hydroxyanisole.

[0042] 2. Preparation of photocurable rosin-based polyester resin for UV offset printing ink

[0043] (1) Under the protection of inert gas, 25.0g phthalic anhydride, 5.0g terephthalic acid, 20.0g isophthalic acid, 10.0g maleic rosin, 15.0g ethylene glycol, 8.0g 1,2- Propylene glycol, 7.0g trimethylolpropane, 0.1g methanesulfonic acid, 0.1g hydroquinone, and 0.1g butyl hydroxyanisole...

Embodiment 2

[0059] A kind of UV offset printing ink of the present embodiment comprises the UV offset printing ink that is made by photocuring rosin-based polyester resin for UV offset printing ink, is to adopt and comprise the following steps to make:

[0060] 1. Prepare materials

[0061] Raw materials are prepared according to the following weight ratio: 15.0g isophthalic acid, 5.0g maleic anhydride, 40.0g acrylic rosin, 10.0g maleic rosin, 10.0g ethylene glycol, 5.0g 1,6-hexanediol, 15.0g ten Octalol, 1.0g tetrabutyl titanate, 1.0g p-hydroxyanisole, 0.5g 2,4-di-tert-butyl-p-cresol

[0062] 2. Preparation of photocurable rosin-based polyester resin for UV offset printing ink

[0063] (1) Under the protection of inert gas, 15.0g of isophthalic acid, 5.0g of maleic anhydride, 40.0g of acrylic rosin, 10.0g of maleic rosin, 10.0g of ethylene glycol, 5.0g of 1,6-hexanediol, 1.0 g tetrabutyl titanate, 1.0 g p-hydroxyanisole, and 0.5 g 2,4-di-tert-butyl-p-cresol are added to a four-necked f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com