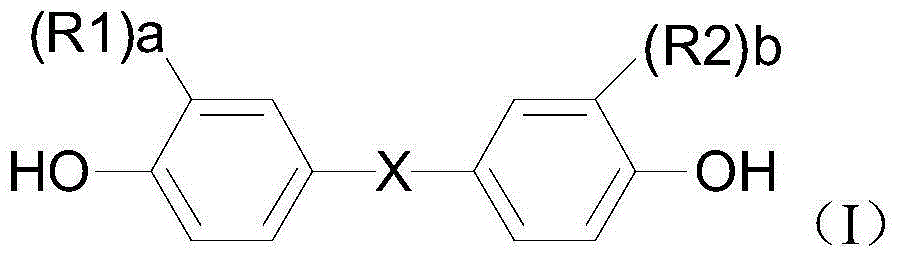

Polycarbonate resin composition with high haze and high light transmittance, and preparation method thereof

一种聚碳酸酯树脂、高透光率的技术,应用在化学仪器和方法、合成树脂层状产品、清洁设备等方向,能够解决无法光扩散材料使用、透光率只有40%等问题,达到节约大量能源、高透光率、减少能量损耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

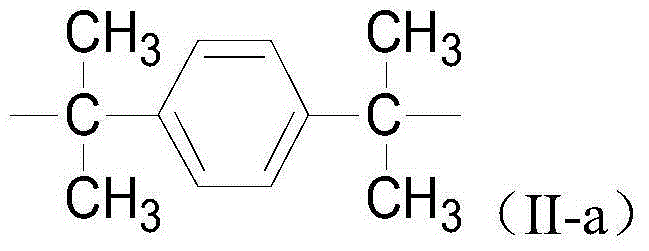

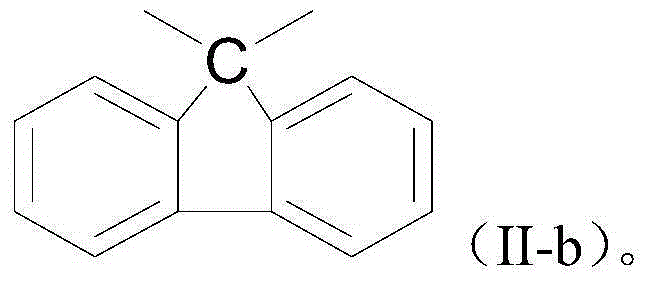

Method used

Image

Examples

Embodiment 1

[0046] Polycarbonate resin (Bayer, Germany, brand 2405) was dried in a blast oven at 120°C for 4 hours, and silicone resin microspheres (Momentive, brand TOSPEARL3120, particle size 12 microns), cross-linked copolymer microspheres ( Self-made, particle size 0.1 micron, styrene content (molar ratio) is 40% in the copolymer, maleamide content (molar ratio) is 40%, crosslinking agent divinylbenzene, its content (molar ratio) 20%) , Antioxidant 1010 is mixed evenly, and wherein by 100 weight parts of polycarbonate resin, organic silicon resin microsphere 0.05 weight part, cross-linked copolymer microsphere 5 weight part, antioxidant 0.1 weight part, in twin-screw extrusion Blending is carried out in the extruder, the temperature of the feeding section of the extruder is 200-240°C, the temperature of the mixing section is 240-280°C, and the temperature of the head is 200-240°C. After extrusion and granulation, it is injected into a standard sample for testing. The test results List...

Embodiment 2

[0054] Polycarbonate resin (Bayer, Germany, brand ET3113) was dried in a blast oven at 120°C for 4 hours, and silicone resin microspheres (Dow Corning Company, brand 30-424, particle size 2 microns), cross-linked copolymer microspheres Balls (self-made, particle size 0.3 micron, styrene content (molar ratio) in the copolymer is 65%, maleamide content (molar ratio) is 33.5%, crosslinking agent is EGDMA, and its content (molar ratio) is 1.5%) , Antioxidant 168 is mixed evenly, and wherein by 100 weight parts of polycarbonate resin, organic silicon resin microsphere 0.1 weight part, cross-linked copolymer microsphere 3 weight part, antioxidant 0.1 weight part, in twin-screw extrusion Blending is carried out in the extruder, the temperature of the feeding section of the extruder is 200-240°C, the temperature of the mixing section is 240-280°C, and the temperature of the head is 200-240°C. After extrusion and granulation, it is injected into a standard sample for testing. The test r...

Embodiment 3

[0062] Polycarbonate resin (Bayer, Germany, brand 3103) was dried in a blast oven at 120°C for 6 hours, and silicone resin microspheres (Dow Corning Company, brand 30-424, particle size 2 microns), cross-linked copolymer microspheres Ball (self-made, particle size 0.8 micron, α-methylstyrene content (molar ratio) is 45% in the copolymer, maleic anhydride content (molar ratio) is 45%, crosslinking agent is EGDMA, and its content (molar ratio) 10%), antioxidant B225 are mixed evenly, and wherein by polycarbonate resin 100 weight parts, organic silicon resin microsphere 0.3 weight part, cross-linked copolymer microsphere 1.5 weight part, antioxidant 0.1 weight part, in double Blending is carried out in a screw extruder. The temperature of the feeding section of the extruder is 200-240°C, the temperature of the mixing section is 240-280°C, and the temperature of the head is 200-240°C. After extrusion and granulation, it is injected into a standard sample for testing , and the test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hazing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com