Alkaline complex unhairing enzyme preparation for tanning and application process of alkaline complex unhairing enzyme preparation

A hair removal enzyme and alkaline technology, applied in the field of leather clean production, can solve the problems of endless hair removal, long hair removal time, damage, etc., and achieve the effects of reducing pollution load, increasing reuse value, and eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

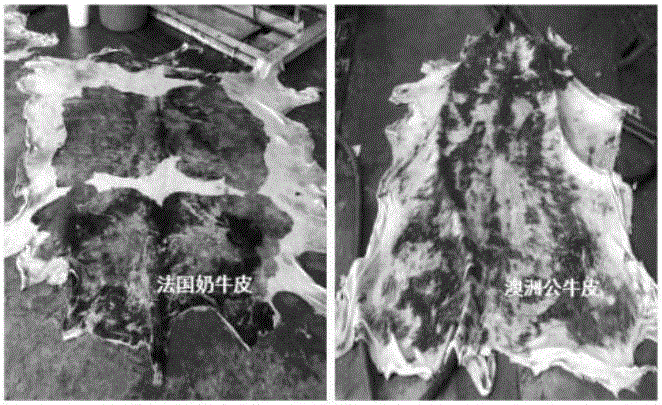

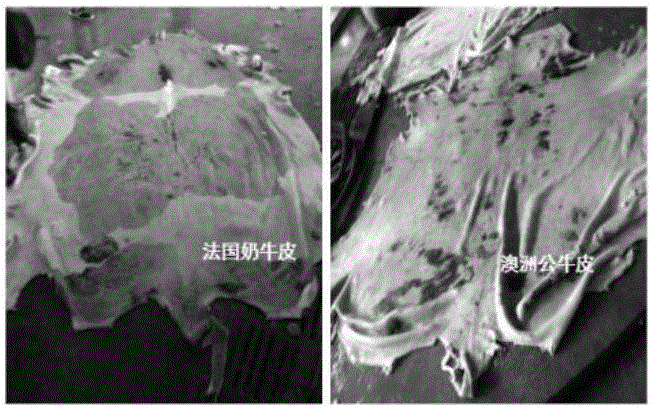

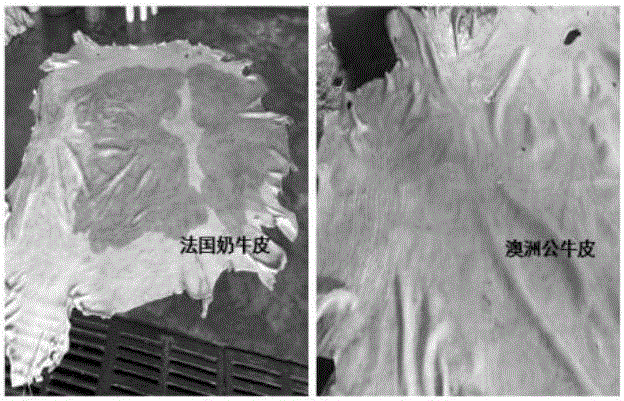

Image

Examples

Embodiment 1

[0039] Embodiment 1: There is warm and bath depilation in the yellow cowhide drum

[0040] The optimum pH value is 7.6-12, and the enzyme activity is 100,000 units / g. Keratinase AK 3kg produced by Heben Biotechnology Co., Ltd.; the optimum pH value is 3-12, and the enzyme activity is 100,000 units / g 1kg of lipase LP-1000 produced by Jiangsu Boli Biological Products Co., Ltd.; 1kg of 2709 protease with optimum pH value of 9-12 and enzyme activity of 50,000 units / g; calcium phosphate 1kg; osmotic agent T 3kg; carbonic acid Sodium hydrogen 30kg; sodium carbonate 15.5kg; sodium dihydrogen phosphate 5kg; sodium tripolyphosphate 2kg; kaolin 4kg; starch 1.5kg;

[0041] Take 100kg of animal skins soaked in water and de-fleshed according to the conventional method, put them into the drum, adjust the temperature to 30-35°C, add 100kg of water at the same temperature, adjust the pH value to 8.5-10.5, first add 0.2kg of lipase ZG, and degrease Process for 90-120 minutes. Without changin...

Embodiment 2

[0042] Embodiment 2: Water immersion depilation in yellow cowhide drum (slotted)

[0043] The optimum pH value is 7.6-12, and the enzyme activity is 100,000 units / g. Keratinase AK 3kg produced by Heben Biotechnology Co., Ltd.; the optimum pH value is 3.0-12, and the enzyme activity is 100,000 units / g 1kg of lipase LP-1000 produced by Jiangsu Boli Biological Products Co., Ltd.; 1kg of 2709 protease with optimum pH value of 9-12 and enzyme activity of 50,000 units / g; calcium chloride 1kg; Pingpingjia 3kg; carbonic acid Sodium hydrogen 30kg; sodium carbonate 15.5kg; sodium dihydrogen phosphate 5kg; sodium tripolyphosphate 2kg; kaolin 4kg; starch 1.5kg;

[0044] Take 100kg of salted yellow cowhide and put it into the drum, add 300kg of warm water (30-34°C), wash for 20 minutes, and discard the waste water; add 300kg of warm water (30-34°C), wash for 20 minutes, and discard the waste water. Add 100kg of water to adjust the temperature to 34-35°C, adjust the pH value to 9.0-9.5 wit...

Embodiment 3

[0045] Embodiment 3: pigskin rolling enzyme, coating enzyme stacking depilation

[0046] The optimum pH value is 7.6-12, and the enzyme activity is 100,000 units / g. Keratinase AK 6kg produced by Heben Biotechnology Co., Ltd.; the optimum pH value is 3.0-12, and the enzyme activity is 100,000 units / g 2kg of lipase LP-1000 produced by Jiangsu Boli Biological Products Co., Ltd.; 1kg of 2709 protease with optimum pH value of 9-12 and enzyme activity of 50,000 units / g; calcium chloride 1kg; JFC 1kg; twelve 2kg of sodium alkyl sulfate; 30kg of sodium bicarbonate; 15.5kg of sodium carbonate; 5kg of sodium dihydrogen phosphate; 2kg of sodium tripolyphosphate; 5.5kg of wood flour;

[0047] Take 100 parts of pigskin after soaking in water, removing meat and degreasing according to the conventional method, put it into the drum, adjust the temperature to 32 ° C, control the water, add 6 kg of sodium chloride, 0.2 kg of bactericidal preservative into the drum, and rotate for 40 minutes Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com