Unhairing enzyme preparation and unhairing method using same

A depilatory enzyme and preparation technology, applied in the field of tanning enzyme depilation technology, can solve the problems of loose surface, rotten surface, affecting the mechanical properties of finished leather, etc., achieve strong removal effect, reduce pollution, and realize the effect of clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

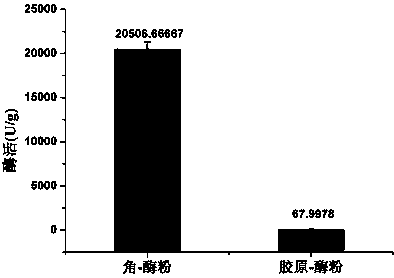

[0034] Example 1, a depilatory enzyme preparation prepared by compounding heparanase, lipase and WB 600 / KerT keratinase at an enzyme activity ratio of 3:3:5.

[0035] The WB 600 / KerT keratinase is derived from Bacillus, and its activity is 5000-100000 U / g; WB600 / KerT keratinase acts on goat leather at an enzyme concentration of 30-1000 U / mL, and the enzyme can also act on cowhide and pigskin.

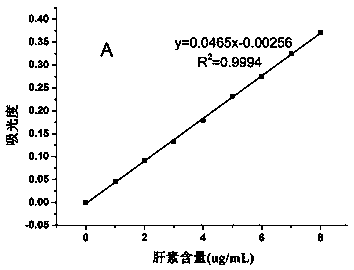

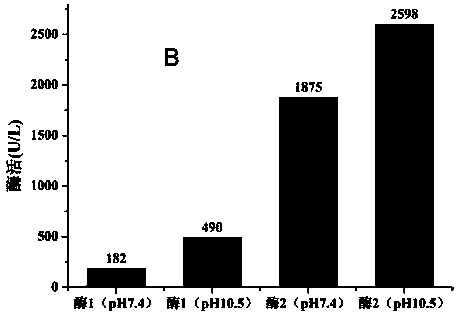

[0036] The heparinase is derived from Bacillus, which has a high activity of degrading heparin, and its heparin activity is 100-3000 U / L; it acts on goat leather at an enzyme concentration of 100-1000 U / L, and the enzyme can also act on cowhide and pigskin.

[0037] In addition to WB600 / KerT keratinase, heparanase and lipase, trace amounts of sodium sulfide can also be selectively added in its application process. The amount of sodium sulfide added is 0.05%-0.5% of the skin weight, and it is added 3-8 hours after the action of the enzyme preparation.

[0038] The application method o...

Embodiment 2

[0039] Embodiment 2, a kind of method of applying this enzyme preparation to remove goat fur, comprises the following steps:

[0040] (1) Choose goat skin, conduct routine immersion and de-flesh treatment.

[0041] (2) Hair removal treatment: carried out in a drum, the water consumption is 60% of the tare weight, and the hair removal enzyme contains 20 U / mL of heparanase, 50 U / mL of keratinase, and 70 U / mL of lipase. After reacting for 3 hours, add 0.05% sodium sulfide by tare, and react for 1 hour.

[0042] (3) Conventional liming and pickling operations, and weighing of pickled skins.

[0043] (4) The weight of the pickled leather is increased by 30%, and the aldehyde tanning (ie glutaraldehyde) and vegetable tanning are carried out. The order of adding the two tanning agents can be changed mutually.

Embodiment 3

[0044] Embodiment 3: a kind of method of applying this enzyme preparation to go off yellow cattle fur, comprises the following steps:

[0045] (1) Select yellow cowhide for conventional soaking and de-fleshing treatment.

[0046] Hair removal treatment: carried out in a drum, the amount of water used is 40% of the skin weight, and the hair removal enzyme contains 30 U / mL of heparanase, 80 U / mL of keratinase, and 50 U / mL of lipase. After drum depilation for 5 hours, add 0.5% lime and let stand overnight.

[0047] (2) Routine liming and pickling operations, and weighing of pickled skins.

[0048] (3) The weight of the pickled leather is increased by 30%, and the aldehyde tanning (ie glutaraldehyde) and vegetable tanning are carried out. The order of adding the two tanning agents can be changed mutually.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com