A polydopamine-coated vanadium dioxide composite powder-based intelligent temperature-regulating textile and its manufacturing process

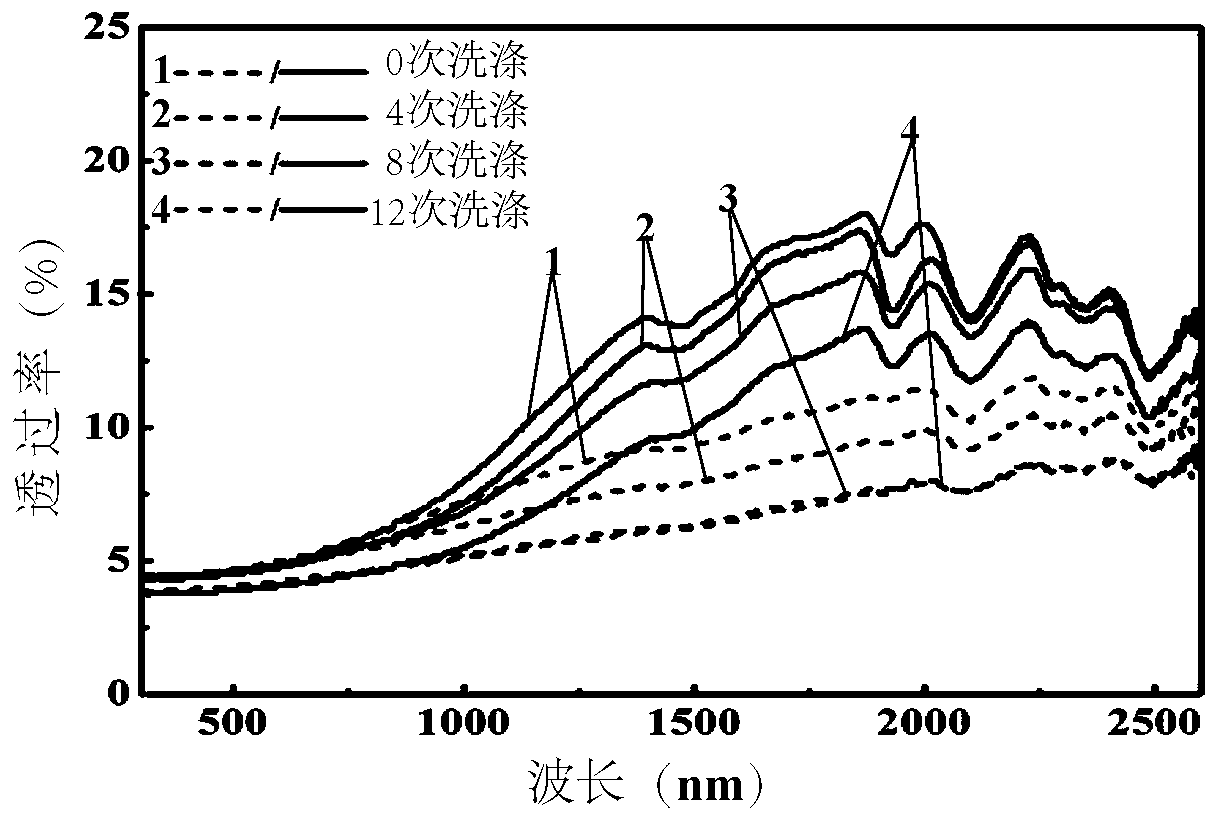

A vanadium dioxide and composite powder technology, applied in textiles and papermaking, plant fibers, fiber processing, etc., can solve problems such as phase change material failure, clothing durability material leakage, skin poisoning, etc., to enhance bonding force, slow down Oxidation time, the effect of improving the degree of washing and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation of finishing agents. The finishing agent is obtained by dissolving polydopamine-coated vanadium dioxide composite powder in deionized water. The mass percent of the polydopamine-coated vanadium dioxide composite powder in the finishing agent can be 0.2-1 wt%.

[0030] Submerge the pretreated textile substrate in the finishing agent for 0.5 to 5 hours, so that the textile can fully absorb the finishing agent, and make the functional particles adhere to the textile fiber. After taking it out, roll it repeatedly with a rolling wheel, and keep the liquid rolling rate at 70% to 90%. Repeat this step 2 to 3 times to obtain the textile after natural drying.

[0031] Pretreatment of textile substrates. The textile substrate is put into a sodium hydroxide solution with a mass fraction of 5-15%, treated in a water bath at 50-100 DEG C for 30-120 minutes, washed and dried to obtain a pre-treated textile substrate. The textiles obtained after the pretreatment remove...

Embodiment 1

[0034] A manufacturing process of polydopamine-coated vanadium dioxide composite powder-based intelligent temperature-regulating textiles:

[0035] Using vanadium dioxide and polydopamine with a mass ratio of 1:2 to prepare polydopamine-coated vanadium dioxide nanocomposite powder, and then dissolve it in deionized water to prepare a finishing agent with a concentration of 0.2wt%;

[0036] Cotton cloth is pretreated with sodium hydroxide;

[0037] Use a shaker to immerse 6-8g of the pre-treated textile substrate into the finishing agent, take it out, and roll it repeatedly with a rolling wheel to keep the liquid rolling rate at 70%-90%;

[0038] Repeat the "immersion-rolling" process 2 times (two dipping and two rolling);

[0039] The treated textiles are naturally dried to obtain polydopamine-coated vanadium dioxide-based functional textiles.

[0040] Compared with the pre-treated textiles, the part with increased mass should be the polydopamine-coated vanadium dioxide comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com