Shell resonator with impact resistance

An anti-shock and resonator technology, applied in the field of vibration resonators, can solve the problems of reducing the sensitivity of hemispherical resonant gyroscopes, difficult electrode integrated preparation or assembly design and preparation, etc., to improve environmental robustness and impact resistance, Achieve the effect of quality factor and reduce processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

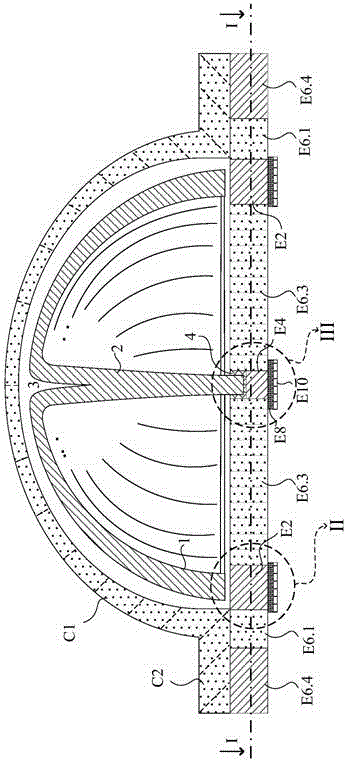

[0040] Such as Figure 1a-Figure 1e As shown, the shell resonator with shock resistance provided by this example includes:

[0041] A hemispherical harmonic oscillator;

[0042] a substrate for packaging and vertical interconnection;

[0043] Multiple non-planar electrodes embedded in the substrate;

[0044] A glass encapsulation cover for vacuum encapsulation;

[0045] Wherein, the hemispherical resonator is composed of a housing 1 and a self-aligning column 2 located at the inner central axis of the housing 1, and the inner surface of the housing 1 and the surface of the self-aligning column 2 are coated with a layer of conductive layer 6; The self-aligned posts 2 are inserted into the package and vertically interconnected substrates, and connected to the lead-out structure E4 through a layer of conductive wrapping layer 4; the packaged and vertically interconnected substrates are embedded with a plurality of non-planar electrodes, including Drive detection electrode E2 a...

Embodiment 2

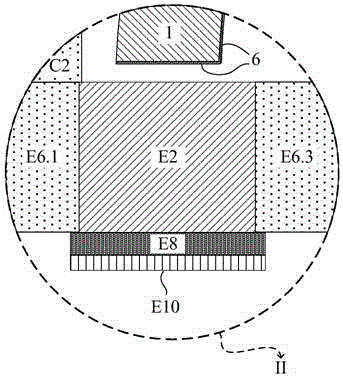

[0057] Such as Figure 2a-Figure 2e As shown, the shell resonator with shock resistance provided by this example includes:

[0058] A hemispherical harmonic oscillator;

[0059] a substrate for packaging and vertical interconnection;

[0060] Multiple non-planar electrodes embedded in the substrate;

[0061] A glass encapsulation cover for vacuum encapsulation;

[0062] Wherein, the hemispherical resonator is composed of a shell 1, a rim 5 and a self-aligning pillar 2 located at the inner central axis of the shell 1, and the inner surface of the shell 1 and the surface of the self-aligning pillar 2 are coated with a layer of conductive Layer 6; the self-aligned pillars 2 are inserted into the substrate of the package and vertical interconnection, and connected to the lead-out structure E4 through a layer of conductive wrapping layer 4; the substrate of the package and vertical interconnection is embedded with a plurality of non-planar electrodes , including drive detection...

Embodiment 3

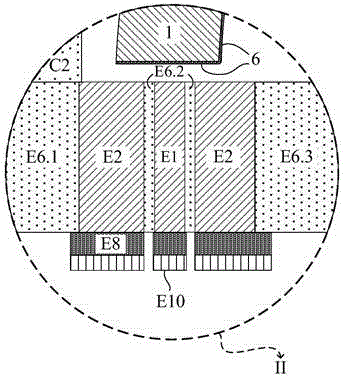

[0075] Such as Figure 3a-Figure 3c As shown, the shell resonator with shock resistance provided by this example includes:

[0076] A hemispherical harmonic oscillator;

[0077] a substrate for packaging and vertical interconnection;

[0078] Multiple non-planar electrodes embedded in the substrate;

[0079] A glass encapsulation cover for vacuum encapsulation;

[0080] Wherein, the hemispherical resonator is composed of a housing 1 and a self-aligning column 2 located at the inner central axis of the housing 1, and the inner surface of the housing 1 and the surface of the self-aligning column 2 are coated with a conductive layer 6; The self-aligned pillars 2 are inserted into the substrate of the packaging and vertical interconnection, and connected to the lead-out structure E4 through a layer of conductive wrapping layer 4; the substrate of the packaging and vertical interconnection is embedded with a plurality of non-planar electrodes, including driving The detection el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com