Flue gas sampling device and method

A flue gas sampling and heating device technology, applied in sampling devices, sampling, measuring devices and other directions, to achieve the effect of improving sampling accuracy, sampling accuracy and instrument service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

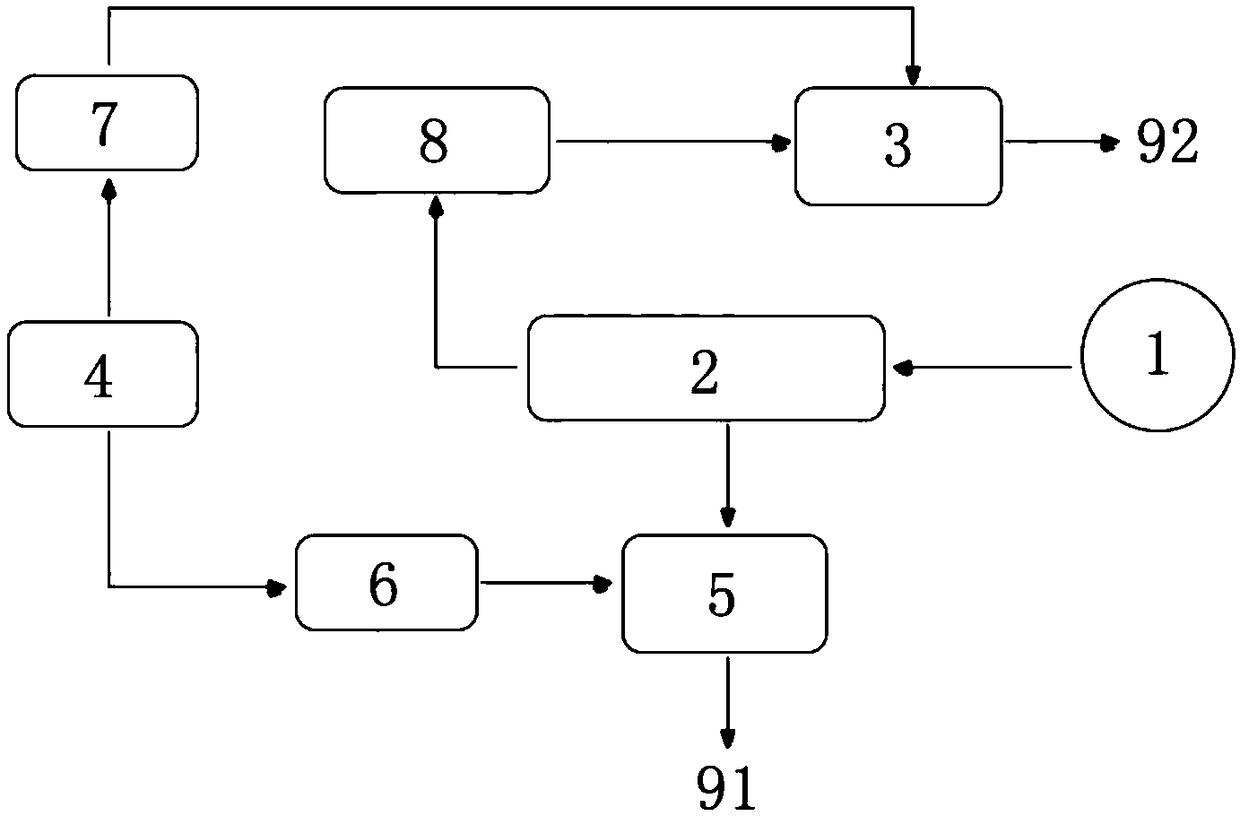

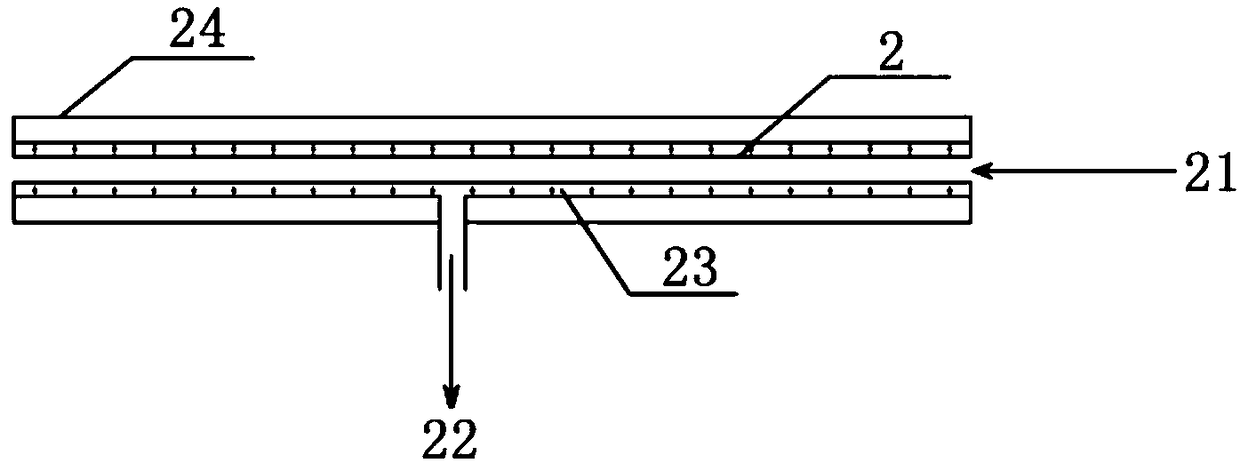

[0029] Such as Figures 1 to 2 As shown, this embodiment is composed of a sampling point 1, a high-speed flue gas sampling pipe 2, a gas injection device 3 and a gas supply device 4, wherein the sampling point 1 is connected to the high-speed flue gas sampling pipe 2, and the gas injection device 3 is a jet pump. The supply device 4 provides compressed air for the gas injection device 3, so that the sampling gas entering the high-speed flue gas sampling pipe 2 from the sampling point 1 reaches an axial flow of 20-30 m / s, and accelerates the dust in the sampling gas; high-speed flue gas sampling The pipe 2 includes a dust-containing channel 21 and a dust-free channel 22 , the dust-containing channel 21 is arranged in the direction of the sampled gas inflow from the sampling point 1 , and the dust-free channel 22 is connected and perpendicular to the dust-containing channel 21 . When the sample gas passes through the dust-containing channel 21, the dust in the high-speed airflow...

Embodiment 2

[0031] Such as Figures 1 to 2 As shown, embodiment 2 adds a heating device 23 and a protective sleeve 24 on the basis of embodiment 1. The high-speed flue gas sampling pipe 2 is composed of a stainless steel pipe plus an inert coating. The selection of the inert coating does not affect the flue gas composition. Just react. The heating device 23 is arranged outside the high-speed flue gas sampling pipe 2, and the high-speed flue gas sampling pipe 2 and the heating device 23 are connected by heat-conducting silicone grease. A protective sleeve 24 is also provided outside the heating device 23 and the high-speed flue gas sampling pipe 2 .

Embodiment 3

[0033] Such as Figures 1 to 2 As shown, embodiment 3 increases the mixing box 5, the first control switch 6, the second control switch 7 and the pressure measuring device 8 on the basis of embodiment 2, the mixing box 5 is an airtight container, respectively connected with the dust-free passage 22 1. The gas supply device 4 is connected to the detection gas outlet 91. After the dust-free sample gas is extracted from the dust-free channel 22, it first enters the mixing box 5 and is diluted with the gas provided by the gas supply device 4, and then is discharged through the detection gas outlet 91. The gas supply device 4 and the mixing box 5 are connected through a first control switch 6, and the first control switch 6 is a proportional valve for controlling the degree of dilution. The gas supply device 4 and the gas injection device 3 are connected through the second control switch 7, the second control switch 7 is a proportional valve used to control the gas flow acceleratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com