Sensor fiber sound emission integrated sensing system and method for monitoring safety of structural body

A sensing optical fiber and sensing system technology, which is applied in the field of distributed sensing optical fiber acoustic emission control devices for sensing structural performance degradation, can solve the problems of short signal transmission distance, less monitoring content, poor resistance to electrical measurement interference, etc. The effect of engineering practical ability, improving monitoring accuracy and reducing monitoring cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

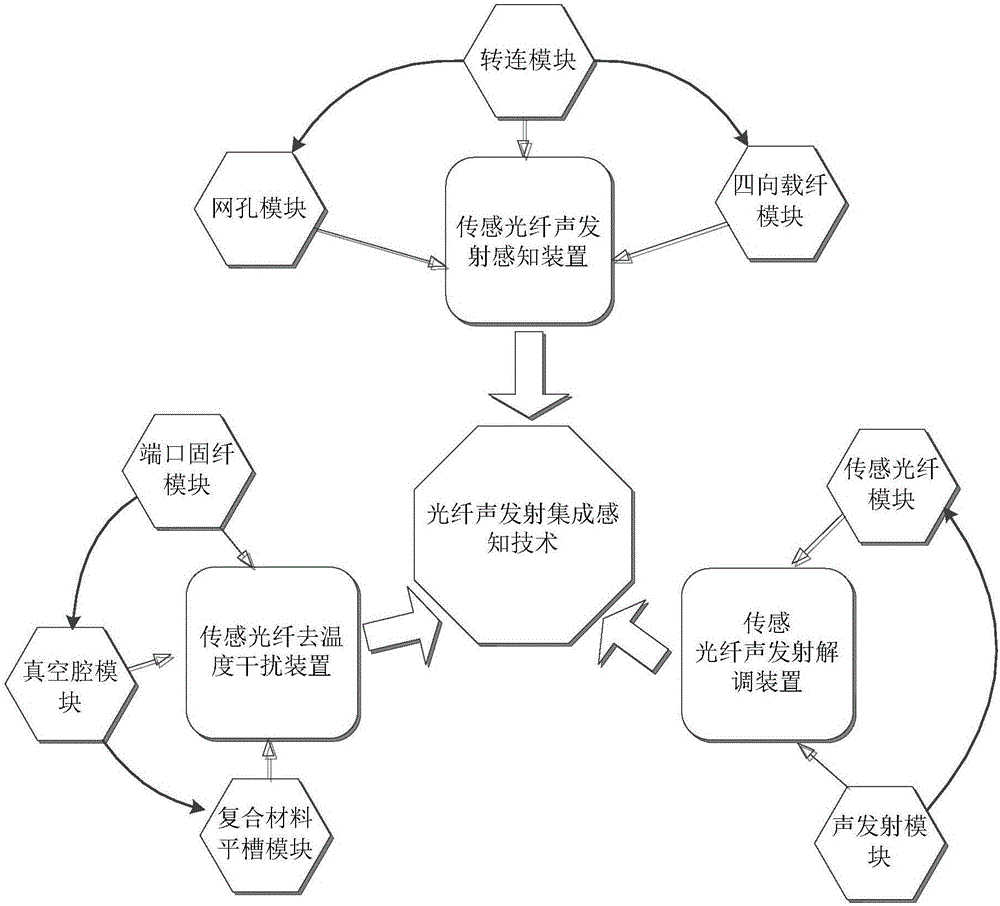

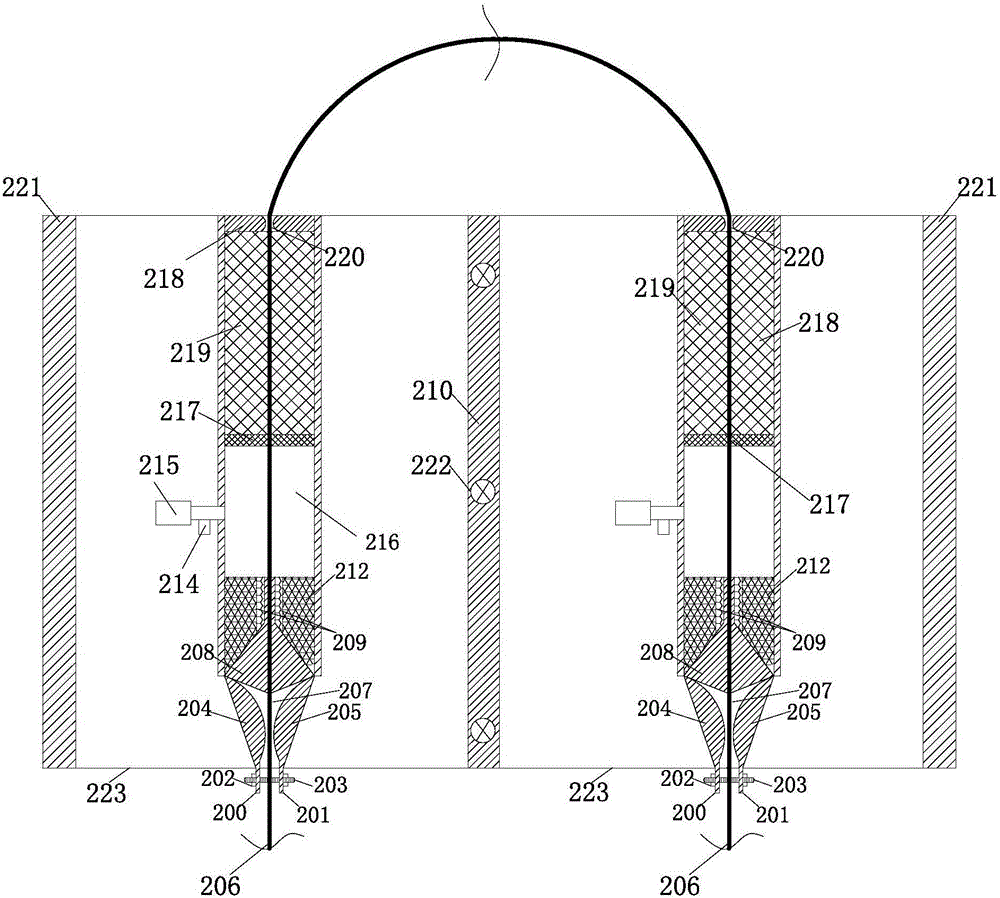

[0029] like Figure 1 to Figure 6 As shown, the sensing optical fiber acoustic emission integrated sensing system for monitoring structure safety of the present invention includes a sensing optical fiber temperature interference removal device and a sensing optical fiber acoustic emission demodulation device, and the sensing optical fiber passes through the sensing optical fiber in turn to remove temperature interference device and sensing optical fiber acoustic emission demodulation device.

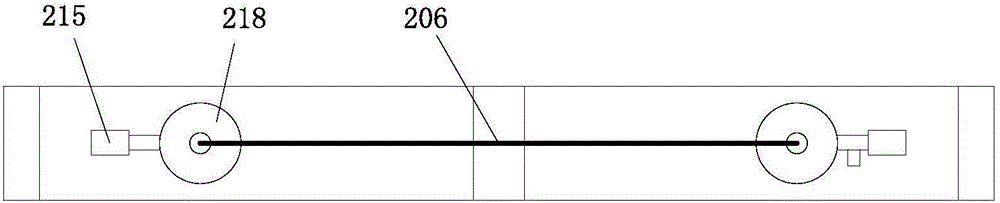

[0030] The sensing optical fiber temperature interference removal device includes a vacuum chamber module, a composite material flat groove module, and a port-fixed fiber module. The vacuum chamber module and the composite material flat groove module are connected by a cover plate 217 with a side length of 2 cm. The vacuum chamber module is connected by a four-corner plug with a length of 2cm between each apex, and the composite material flat groove module is connected with the port-fixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com