Method for injection molding of stainless steel insert and stainless steel insert

A technology of insert injection molding, stainless steel, applied in the direction of coating, etc., to achieve the effect of simplifying the bonding structure, reducing costs, improving bonding strength and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

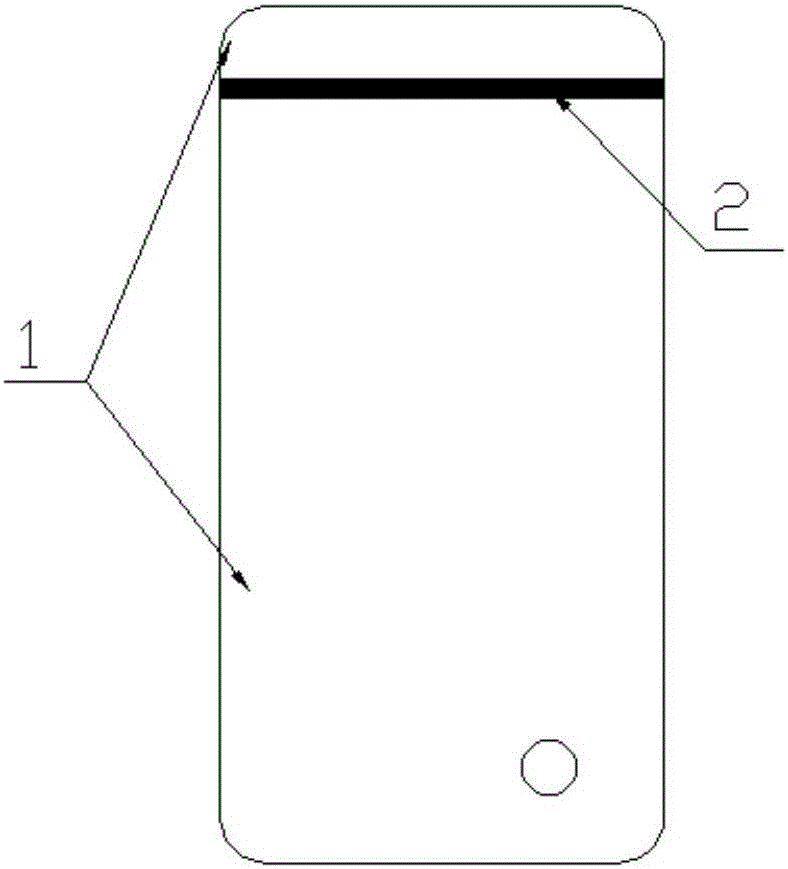

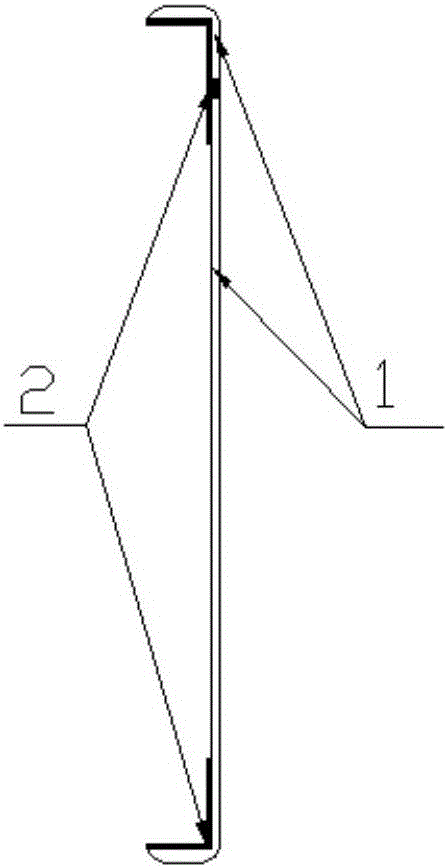

Image

Examples

no. 1 example

[0036]Stainless steel products with a specific structure (material 304) are degreased and cleaned, using degreasing agents commonly used in the market, such as thermal degreasing HY-201 of Pubo Chemical Co., Ltd., degreasing at a temperature of 40-65 degrees Celsius (this time Choose about 55 degrees Celsius), soak in the degreasing agent for 1 to 5 minutes (this time choose about 3 minutes);

[0037] For the sandblasting treatment of stainless steel products, choose 180# ceramic sand, and perform sandblasting at a speed of 10 Hz under a pressure of 2.0kgf, so that the stainless steel products can obtain a rough surface;

[0038] The sandblasted product is injected with PBT plastic. The temperature of the injection mold is 140-170°C (150°C is selected here). During the injection molding process, it is found that the stainless steel metal falls directly and cannot be effectively combined with the plastic.

no. 2 example

[0040] The stainless steel product (material is 304) of specific structure, carries out the sandblasting treatment with the first embodiment, then carries out further degreasing and degreasing, and the degreasing process is the same as the degreasing parameter in the first embodiment, so that the product surface is kept clean;

[0041] Put the stainless steel product into the electrolyte solution with a concentration of 8-30% (the electrolyte solution is composed of acidic or alkaline, active agent and corrosion inhibitor) for electrolysis, the voltage is 1-13V (choose about 10V here), and the time is 5 -60 minutes (choose about 30 minutes here);

[0042] The dried product is injected with PBT plastic, the temperature of the injection mold is 140-170°C (150°C is selected here), and the stainless steel product is annealed at about 150°C for one hour after injection molding;

[0043] After the stainless steel injection molded product is cooled for 4 hours, the pull-out force is ...

no. 3 example

[0045] The stainless steel product (made of 304) with a specific structure is subjected to activation treatment after the same treatment as the second embodiment (before drying) to remove the black or gray hanging ash on the surface produced by electrolysis; the activator is Pubo Chemical Co., Ltd. HY-202 (belonging to the organic acid series), the activation temperature is 20-50 degrees Celsius (choose about 20 degrees Celsius here), and the activation time is 1-10 minutes (choose about 3 minutes here), to ensure that there is no gray stain on the surface of stainless steel products The effect is better if you can also configure ultrasonic waves during activation;

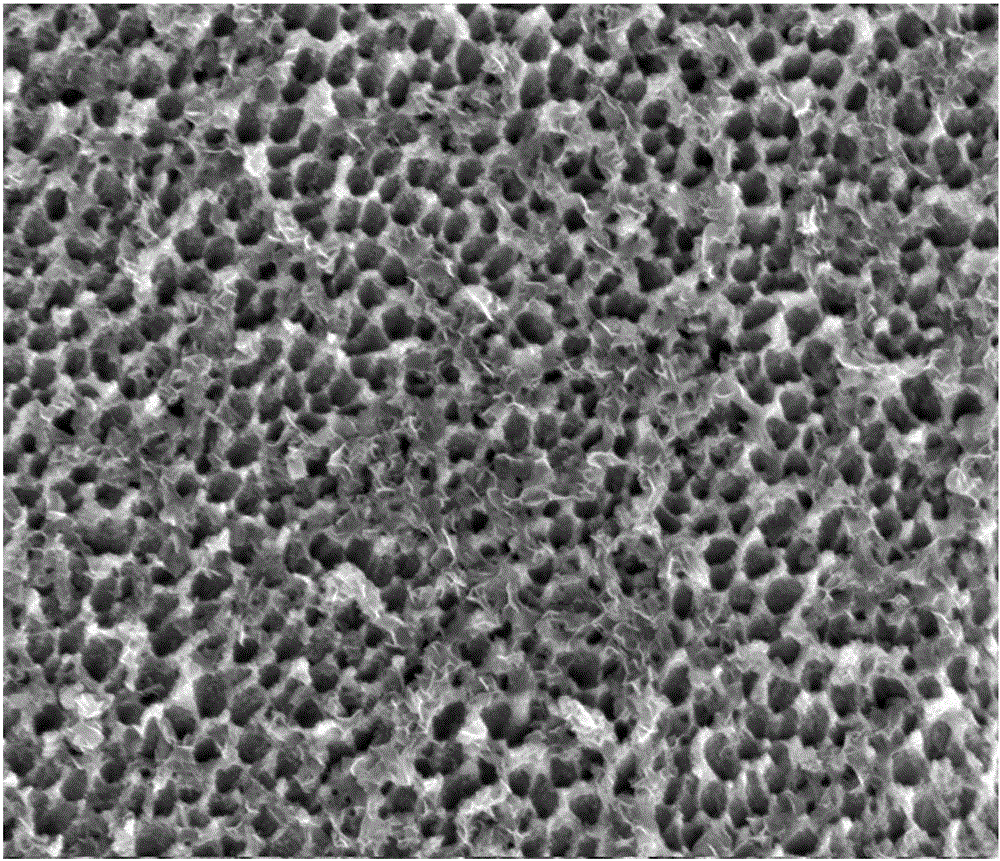

[0046] Then carry out corrosion treatment, the conditions are: in the corrosion solution with a concentration of 20-40%, soak for 60-600 seconds at a temperature of 20-60 degrees Celsius; the corrosion solution includes ammonium chloride, ammonium fluoride, sodium carbonate One or more of them, the pH value of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com