Greasy dirt-resistant oil-water separator

An oil-water separation device and anti-fouling technology, which is applied in the direction of separation methods, liquid separation, grease/oily substance/floating matter removal devices, etc., can solve the problems of poor anti-fouling and clogging performance of organic membranes and poor removal effect that are not suitable for large-scale application. Ideal and other issues, to achieve good oil-water separation effect, good anti-fouling performance, and improve separation efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

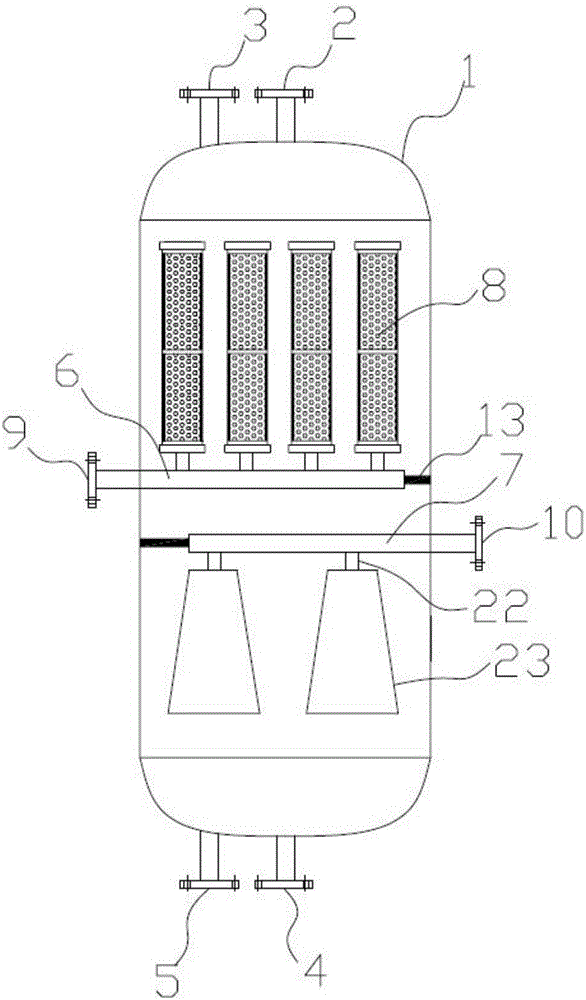

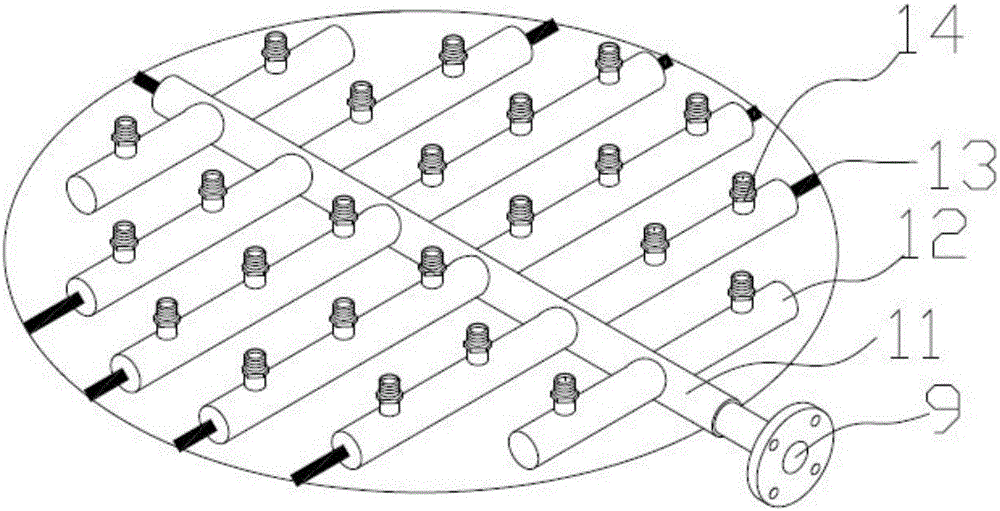

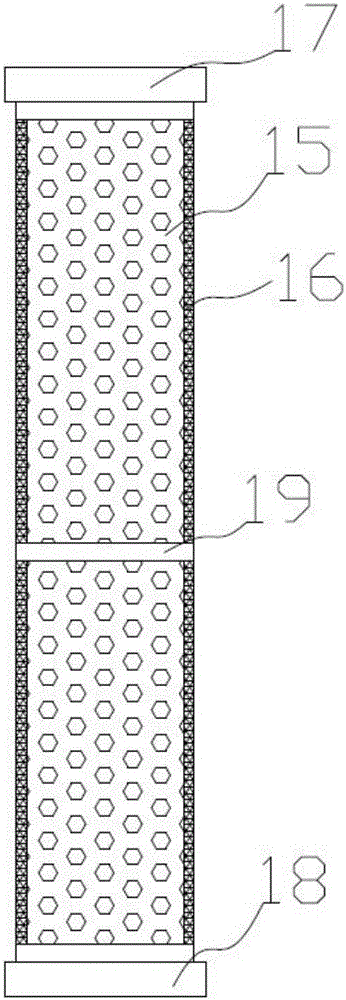

[0027] Such as figure 1 A pollution-resistant oil-water separation device shown includes a tank body 1, a water inlet water device 6, a water outlet water device 7 located below the water outlet water device, a columnar oil-water separation filter element 8 and an outlet water diversion mechanism, and the top of the tank body There is a light oil discharge port 2 and a backwash air inlet 3 for connecting compressed air. The bottom of the tank is provided with a heavy oil discharge port 4 and a sewage discharge port 5. The water inlet water device and the water outlet water device are fixed on the In the tank body, the side wall of the tank body is provided with a water inlet 9 and a water outlet 10, and the water inlet water device includes a water inlet main pipe 11 and a water inlet branch pipe 12 (see figure 2 ), the water inlet main pipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com