Application of Nitrile Group-Containing Compounds as Flame Retardant in Flame Retardant Thermoplastics

A thermoplastic and compound technology, applied in the field of flame retardant thermoplastic modification, to achieve the effect of improving residual quality and reducing smoke factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

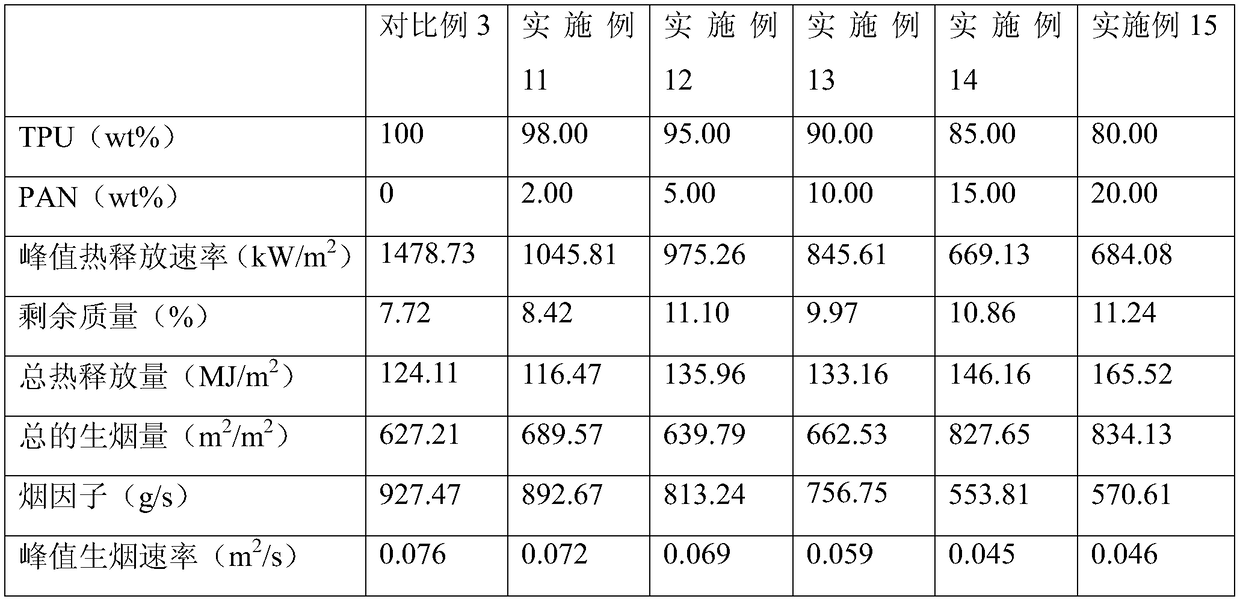

Examples

Embodiment 1

[0022] Butadiene rubber was used as flame retardant to prepare flame retardant thermoplastic polyurethane elastomer composite-1.

[0023] The preparation method of the flame-retardant thermoplastic polyurethane elastomer composite material is:

[0024] 1) Sample preparation, weigh appropriate amount of TPU and BR in advance and put them into containers for later use.

[0025] 2) The temperature of the internal mixer is controlled at 180° C., the rotating speed is 30 rpm, and a thermoplastic polyurethane elastomer with a mass percentage of 98.00 wt % is added to the internal mixer, and after it is melted, 2.00 wt % of TPU is added. Butadiene rubber was melt-blended for 10 minutes, and the composite material was taken out and pressed into shape.

[0026] 3) The obtained material is placed in a constant temperature and humidity test box (25°C, 60% relative humidity) for 72 hours before performance testing.

[0027] 4) The obtained flame-retardant composite material is pressed i...

Embodiment 2

[0029] Butadiene rubber was used as flame retardant to prepare flame retardant thermoplastic polyurethane elastomer composite-2.

[0030] The preparation method of the flame-retardant thermoplastic polyurethane elastomer composite material is:

[0031] 1) The preparation of sample is the same as example 1.

[0032] 2) The temperature of the internal mixer is controlled at 180° C., the rotating speed is 30 rpm, and a thermoplastic polyurethane elastomer with a mass percentage of 95.00 wt % is added to the internal mixer, and after it is melted, 5.00 wt % of TPU is added. Butadiene rubber was melt-blended for 10 minutes, and the composite material was taken out and pressed into shape.

[0033] 3) The obtained material is placed in a constant temperature and humidity test box (25°C, 60% relative humidity) for 72 hours before performance testing.

[0034] 4) The obtained flame-retardant composite material is pressed into 100×100×3mm by a flat vulcanizing machine 3 sample. 35kW...

Embodiment 3

[0036] Butadiene rubber was used as flame retardant to prepare flame-retardant thermoplastic polyurethane elastomer composite-3.

[0037] The preparation method of the flame-retardant thermoplastic polyurethane elastomer composite material is:

[0038] 1) The preparation of sample is the same as example 1.

[0039] 2) The temperature of the internal mixer is controlled at 180° C., the rotating speed is 30 rpm, a thermoplastic polyurethane elastomer with a mass percentage of 90.00 wt % is added to the internal mixer, and after it is melted, 10.00 wt % of TPU is added. Butadiene rubber was melt-blended for 10 minutes, and the composite material was taken out and pressed into shape.

[0040] 3) The obtained material is placed in a constant temperature and humidity test box (25°C, 60% relative humidity) for 72 hours before performance testing.

[0041] 4) The obtained flame-retardant composite material is pressed into 100×100×3mm by a flat vulcanizing machine 3 sample. 35kW / m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com